When someone asks for a servo recommendations for an Extreme Flight model, I can usually share personal experience. When I can't, I have experienced customers and friends whom I trust to help bring me up to speed, if needs be. However, when someone asked about servos for a 48" Edge 540, I could speak with some basis of experience.

This, because I own a 48" Extreme Flight Laser 200 (in the red Bud Light scheme as campaigned by Leo Loudenslager and presently hanging at our National Air and Space museum). It, as well as a Vanquish, another Extreme Flight 48" aircraft (and just about my *favorite* model airplane). And while my Laser 200 isn't an Edge 540, like all these diminutive EF-models which are created for aficionados of XA (extreme aerobatics), they all give you that tiger-by-the-tail flying experience.

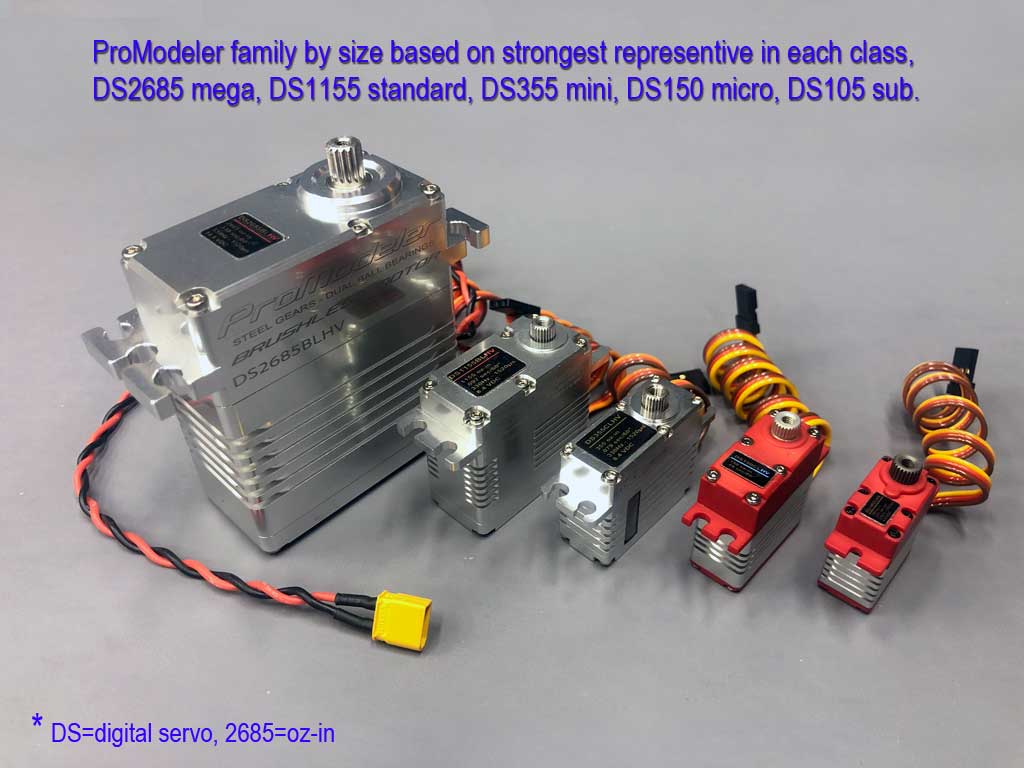

In short, there's no mystery about the servos I'll recommend. You definitely want one of our super subs! As background, we offer 5 basic size-classes, and the subs are our very smallest.

- From our quarter-class, our largest, down through standard, mini, micro, and sub-micro

And while we offer 4 different subs, only two are most suitable for this class of model airplane. Both are hybrid designs. By hybrid meaning the type of construction. Hybrid being a combination of an aluminum center (with cooling fins), plus a lightweight (but reinforced) engineering-polymer upper transmission section.

The alloy center is CNC-machined of 6061-T6 aircraft aluminum. The most important two features of the center case are the motor's a close-fit, and the cooling fins. The purpose of both is to promote shedding heat generated by the motor when the servo is working hard. And let me tell you, when a servo doubles the output of competing servos, it's *because* it's working hard! Shedding the heat is über important!

Anyway, if your only experience with this class of servo are those cheaply made 9g servos found in foam ARFs, or perhaps a much higher quality equivalent, by Hitec, then holding one of these little jewels within your fingers will be an eye opening revelation.

- Diminutive center case is precision machined of 6061-T6 aircraft aluminum

Note; we also have one sub-micro model, which features an all-alloy case. However, this rugged miniature is more frequently used in other applications. For example, micro-turbine powered jet as well as 1/18th and 1/24th scale crawlers - usually mounted on highly custom front axles called portals because they have gear reduction happening at the outboard stubs where wheels/tires are mounted.

- Custom 1/24 scale portal axle features steering via a ProModeler DS125CLHV sub-micro

Anyway, unlike the very rugged DS125CLHV, the ones I am recommending for your Edge 540 have a reinforced engineering-polymer upper case. Regardless, eyeball the splendor that is the DS125CLHV for if you ever find yourself with an application that requires something like this.

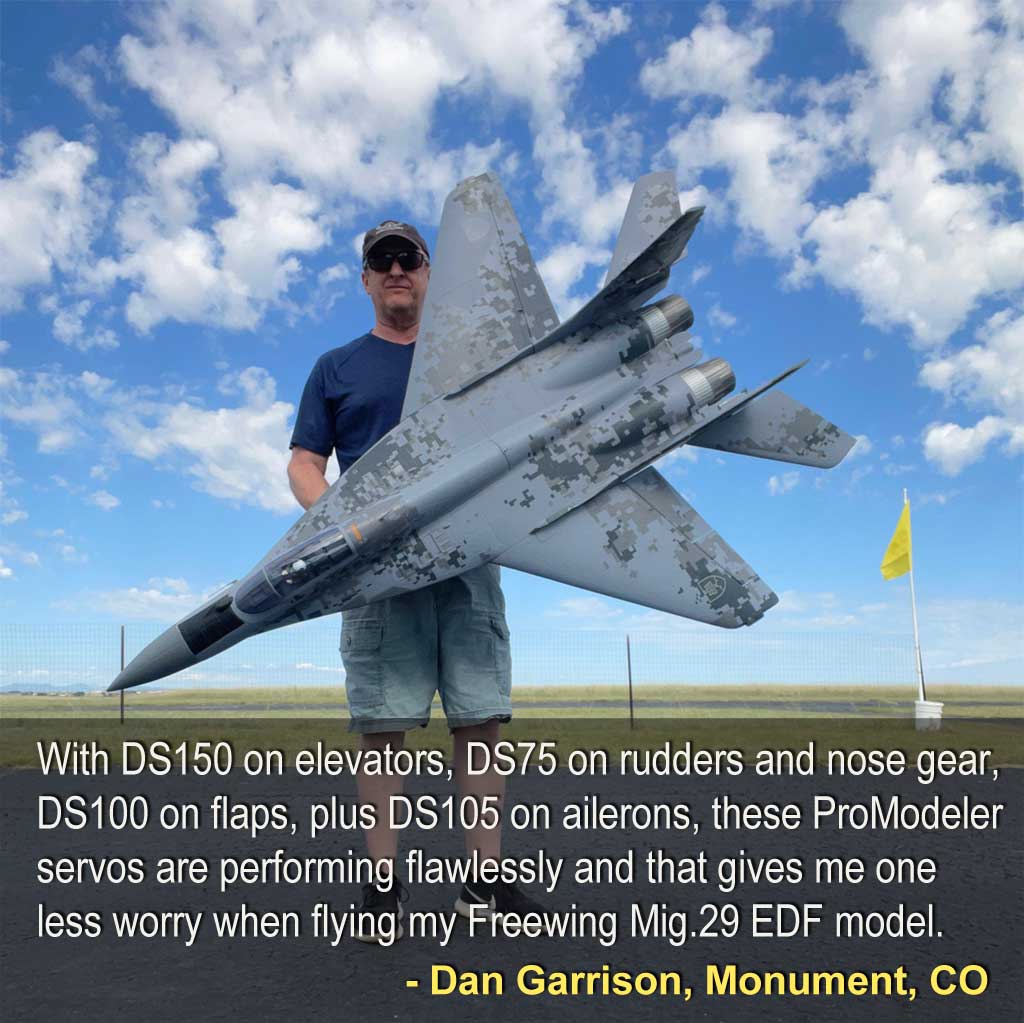

So who else uses the DS75CLHV and DS105CLHV? The guys flying foam jets are big time customers for these servos. And the funny thing is, they pony up $600-800 for a model equipped with a butt load of 9g-class servos only to declare them junk after a few flights and come to us and then complain about paying another $400 for good servos. As if it were our fault!

Thing is, as hot rodders know, speed costs and the folks flying EDF and miniature turbine powered jets are the *speed costs* side of flying model airplanes!

Anyway, if you're the sort to appreciate beauty in all things mechanical, then you'll especially appreciate the details of this DS125CLHV servo gear train. Details to appreciate include the thin shim fitted beneath the o-ring on the output shaft to provide compression for sealing, to the tiny bronze hardpoints pressed into the aluminum alloy case. These, expressly to reinforce where the steel gear shafts for the transmission are fitted to prevent the round bores becoming egg-shaped under repeated loads. More later.

- Note, even our all-alloy case sub-micro receives bronze reinforcements of the case

With with regard the two hybrid submicro servos, the reinforcements come in two forms. First the polymer being used (plastic in other words) is nylon 6.6 meaning it's reinforced with glass fibers. As compared to bog standard nylon, this polymer gets additionally stiffness and tensile strength from the fibers, which act like rebar in concrete.

The other reinforcement is literally a mechanical reinforcement of the plastic by Much harder than aluminum and approaching steel in strength, using bits of bronze in plastic where the gear shafts fit means deformation under repeated load is a thing of the past.

These tiny bits of bronze essentially create hard points within the plastic where we press them into the case. Precision turned on a Swiss lathe, we outsource the manufacture of the inserts to a specialist whose focus is high precision (its really hard to beat a man at his craft).

- Molded in reinforced nylon 6.6 *and* reinforced further with tiny bronze inserts

Use of the DS75CLHV and DS105CLHV in things that fly

So for a 48" model, even if you can afford the all-alloy version of our sub-micro DS125CLHV servo, you really would rather have one of our hybrids. This, principally because they're lighter (and because they don't cost as much).

So which are the two servos we recommend for your Edge 540? Our DS75CLHV and DS105CLHV. And either one is perfect for the job. Which is better? Well . . . define better! By the way, if you're wondering, you don't really need a decoder ring to suss out our part numbers because;

- DS = Digital Servo

- 75 = torque rating in oz-in

- CL = Coreless motor

- HV = High Voltage (to 8.4V)

Better than what else is available in this class? That's for you to decide. But compared to sub-micro servos created just a few years back, these tiny servos may be the same physical size, yet instead of outputting 30-50g, they output a lot more.

Note; subs in this class may range in mass up to 20g yet are often referred to as 9g-class.

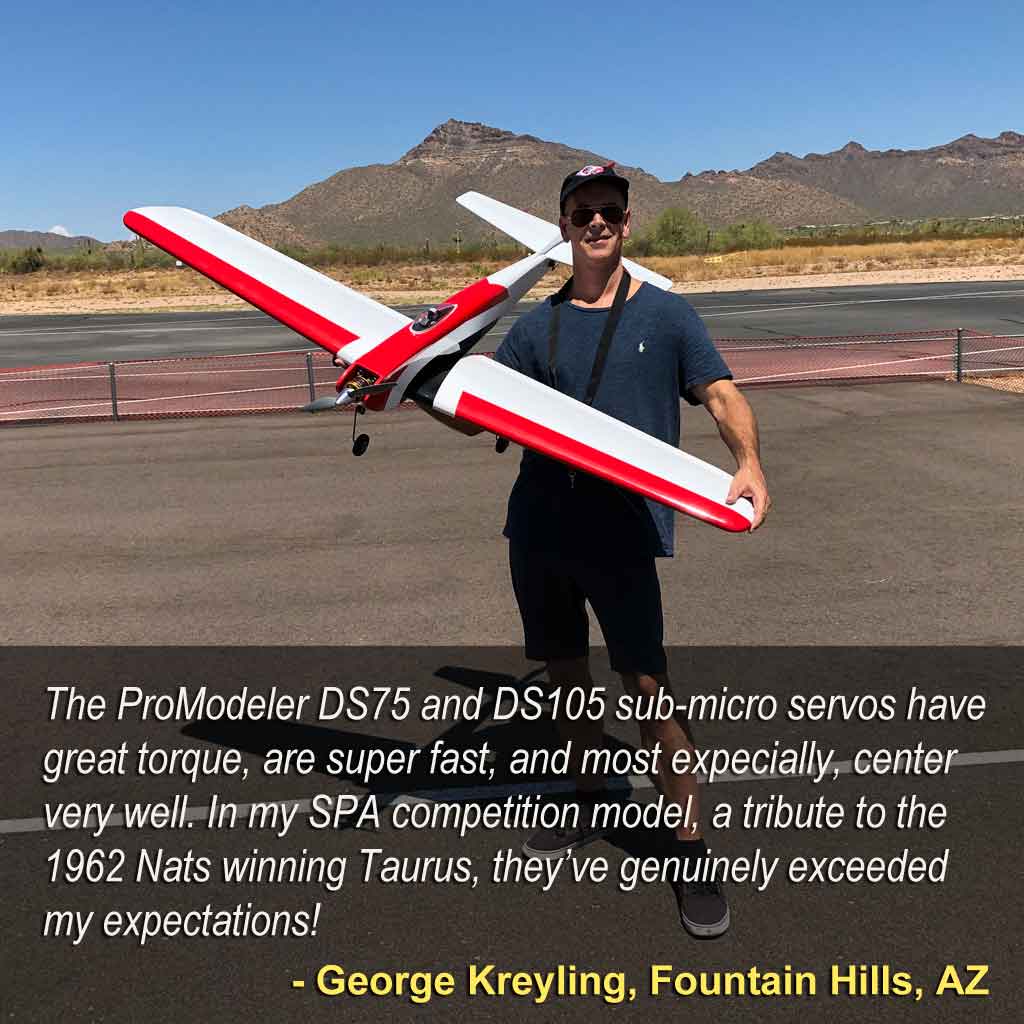

So these mouse-size servos are incredibly powerful and offer precise centering. For those of you who appreciate these benefits - in addition to finding use in XA model aircraft - knowing they are favored by competition aerobatic pilot , may be important.

These pilots, instead of flying brutal XA-class maneuvers fly with finesse. They exhibit a deft touch in flying what are called precision pattern birds. For them, centering is the single-most important characteristic. For them, centering tops power and speed.

So if precision maneuvers are defined as beauty, and XA are the beast of maneuvers, then with the DS75 and DS105 you're getting beauty *and* the beast!

So which is the best one for you, the DS75CLHV or the DS105CLHV? Well, this depends. When select either our DS75CLHV or DS105CLHV (sister servos, where you pony up an extra 10 bucks for the 105), you're getting the best we know how to make.

Whether you can tell the different is not for us to say, either. And other than the added power, they're nearly the same-same servo) in depends on how hard you fly. And frankly, most folks reading this will be perfectly happy with the DS75CLHV.

Look, let's be honest, you need to be the second coming of Jase Dussia to feel the difference the 40% more powerful DS105 gives you versus the DS75. There's a much greater amount of torque between the DS75CLHV and the DS105CLHV than most pilots can feel (other than in your wallet).

No, we're not going to leave you dangling, we'll give you the means to decide in a bit. but first, and circling back around to a few details about the full scale Edge 540. If you're not in the know, the Edge 540 is a product of Zivko Aeronatics near Oklahoma City, OK.

Means it's Made in USA. Also, perhaps your first exposure to the aircraft came through the super popular Red Bull series, where the Edge 540 was the platform of choice. And it's a looker, too.

From any given angle, like this right-rear quartering-view, for example, the subtle beauty of the elegant design is readily apparent. Like just look at this thing! Gorgeous, eh?

- With the sun just about to begin going below the horizon, time for a few after-work flights!

Note; this aircraft features a single-place canopy because it flies with just one pilot. Unlike many aerobatic aircraft where there are two seats fitted, this one is never used as a training aircraft.

Here's a little know fact, many full scale aerobatic aircraft are configured in tandem expressly so the pilot flies and instructs from the rear. This is because the airshow circuit isn't exactly lucrative work. Glamorous? Yes. But get rich flying? Nope!

So because this kind of flying is something you do out of love instead of for the lucre, pilots on the airshow circuit often boost their income with a spot of unusual attitude instruction, and/or aerobatic instruction. This, by the way, explains why so many aerobatic aircraft have the long canopy indicative of a tandem set up (fore-and-aft pilot seating versus side-by-side, like in a Cessna or Cirrus) versus the single place canopy of the Edge 540.

In short, the Edge 540, whether fulls-scale - or a tiny example like the 48" wingspan replica produced by Extreme Flight - isn't a toy. Far from it! Just as a true craftsman isn'tt defined by his tools, while a warrior is, in some ways, this Edge 540 is a weapon in the right hands.

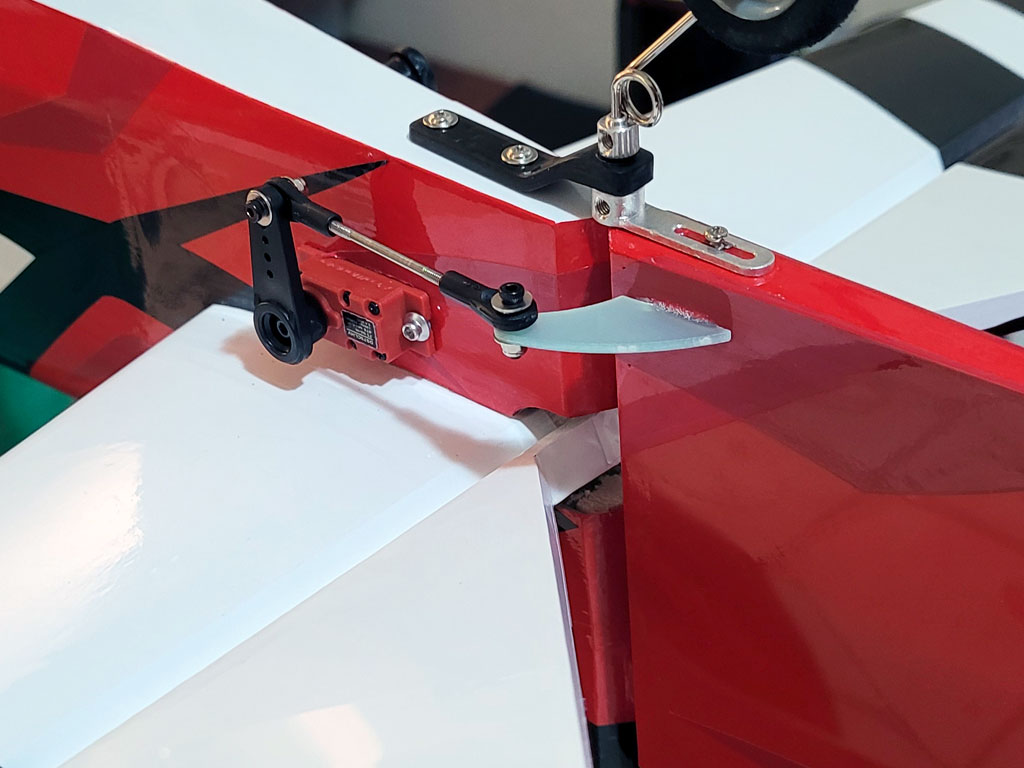

I kid you not if I say it's capable - in your hands - of letting you invent totally new maneuvers with it. So let's look at the servo installation. We'll begin by eyeballing the aileron installation.

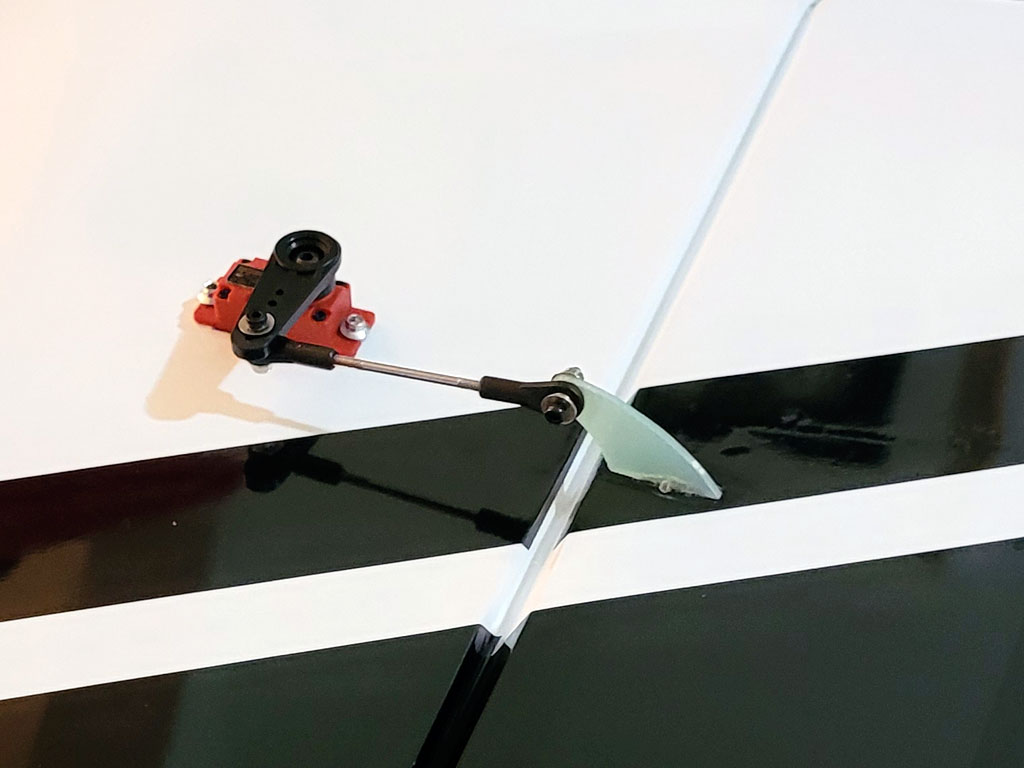

- Featuring a pocket-style servo installation, a short pushrod does the business

Extension-wise for the wing panels, you only need a pair of 4" and a pair of 6"

The 6" connect to the servo lead within the wing panels, and the 4" long extensions connect to the receiver. When you mate the wing panels to the fuselage, that's when you join the 6" extension on the servo lead to the 4" extension connected at the receiver. The trick is knowing which, is which?

Me? I make a simple overhand knot in the right aileron extension at the receiver. This, so I know which-is-which when I make the connection. Some guys like labels, but I'd rather keep it simple because labels can fall of, but you do you. Both methods work.

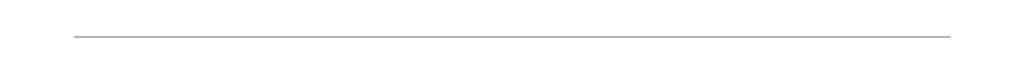

Heads up, we offer both conventional and locking-type extensions. For the 6" ones within the wing panel, my advice is go with the locking type. Meanwhile, for the 4" the shorties at the receiver, you're better off with the non-locking style. This because you'll be removing the connection when disassembling the model.

- Use your thumb nail and lift before pulling the connectors apart - easy peasy!

Next, please allow me a crass bit of self-promotion

What many pilots like about ProModeler extensions versus whatever you buy from hobby dealers are they're insulated with silicone instead of PVC. This means they're very soft and supple, which lets them be routed through tight spots and around sharp corners better. That, and the silicone rubber resists abrasion better.

They're also twisted instead of flat so if the ESC ever begins to fail and emit stray RFI, then the twisting resists allowing the signal to make it into your receiver. And without getting too deep into the weeds, the theory behind twisting it it reduces the

strength of noise signals *and* cancels out external RFI-waves by moving a part of the noise in the direction of the signal and another part in the opposite direction.

Honestly, this is a bigger deal with folks flying ignition powered engines *but* it's worth a thought with electric-powered models, too. Heads up!

Next, let's see what is involved with rudder and elevator servo installation. Rudder first.

- A tidy installation, note the supplied Allen-head mounting screws - they're the good ones!

Tucked beneath the stab, and secured with a pair of screws as usual, this photo also shows off the very nice tail wheel bracket as supplied by Extreme Flight. Me? I've been known to use one of these on others models because it's so nice! Kudos to the crew at Extreme Flight for going the extra mile with the hardware package.

What's left? The elevator servo installation!

- Another short pushrod connects your servo with the elevator surfaces - no lost motion!

ProTip: I'd like to share a thought for if you're a hard flying pilot. Saying if you're flying like the 2nd coming of Jase Dusia, then you may want to kick things up a notch servo-wise.

By this I mean consider upgrading the elevator servo to the next larger size. A DS100DLHV will do the trick, and this is the same servo used in many 52" models and it's entirely because the gears are physically larger, meaning more robust.

Do you need to? Absolutely not! Just saying, there's a range of 3D pilots ranging form gentleman-3D to holligan-3D. Honestly, we don't know you so we can share our thoughts but it's up to you, to know you, take my meaning? After all, some pilots are harder on their equipment because they simply fly harder than others - like maybe like they're trying to rip the wings off!

So if this maybe describes you, then this tip is for you. Otherwise, ignore it.

Extensions for the rudder and elevator servos

As with the ailerons, you're going to need a pair of extensions. One each for the rudder servo and the elevator servo. These ones are 18" long and once again, I recommend using the type that lock.

Clicking the link takes you to the ones we offer, use the pull down box to select the locking type. Note, clicking opens a new browser tab so you don't lose your place within this article.

Summary

So while I said most pilots would be delighted with the DS75CLHV, I never said whom amongst you *should* select the DS105CLHV versus the DS75CLHV. It's pretty simple, Pilots who fly hard should. If you're flying rifle rolls, walls, crankshafts and such, then you'd be well advised to pony up for the pricier servo.

If you're a low and slow kind of pilot, e.g. torque rolls, Harrier rolls, falling leafs, then the DS75CHV will delight you with it's performance and precision. But if you're a stick banger, then no question, buy the DS105CLHV.

Finally, while I told you all about our servo, the good points, a bit about the performance. I never said what will make you, you as an extreme performance pilot, want them. It's because they'll last a good long time. No, nothing lasts forever but if you're used to typical imports then you know after less than 50 flights this has likely happened to them.

- The bore where the gear shafts fit gots wallowed out due to the loads being imposed

Basically, what's gone wrong in the photo above are the wicked loads being imposed on the little servo are too much for it. I won't name names because it doesn't really matter since any pilot with experience will know exactly which servo we're talking about. But once the bores go south, then the gear mesh follows. Before long the servo strips or the centering becomes garbage. This kind of model isn't one to tolerate either

Closing thoughts

The kinds of article are what I call a living document. This just means that unlike a magazine review or article, which once it goes to print is one and done and any errors or omissions are handled (if they're even acknowledged) perhaps with an editorial correction at the bottom of page 93 perhaps 6-months later (if at all). With this kind of document, we can come back in and make any correction or updates and presto! Thereafter, anyone who reads it going forward is the beneficiary of updated information. It's a rather nice benefit of web-publishing in my opinion.

Speaking of errors and omissions, any you may notice are mine because, as is mentioned in the Book of Daniel, my feet are made of clay. That, and only God is perfect.

Please clue me in regarding your thoughts and observations and if needs be, then I'll endeavor to correct, or add to them. Also, if you have any flying shots of this model I'd be delighted to add them because they'll add a nice spot of color to what is otherwise a fairly dry presentation.

Lacking one of those, I'll share a neat photo of a micro crawler - of the type that also use this class of sub-micro servo. This little rig is about 8" long, and is based on an Axial SCX24, which means it's a 1/24th scale.

And yes, when tricked out they have this kind of wild suspension travel. Further to this, yes, they can negotiate this kind of terrain - it's their special appeal. What's more, if you've only flown model airplanes and think RC trucks are boring, then have I got news for you because the skill to negotiate what these things can go over is simply off the charts level of fun!

Want to learn more? I urge you to visit my favorite crawler forum, it's dedicated to this one brand and it's known as - Arrma Forum - , which lets out the tiny Axial crawler below, but what the heck, don't let that hold you back because these folks love all kinds/brands of rigs! Like maybe poke around, and if you like what you see, also let 'em know I sent you!

Last thing, you may always reach to me at: 407-302-3361 or via email: info@promodeler.com