Extreme Flight (EF) have a model called a Turbo Bushmaster on their website that's so popular they've been offered it in several different wingspans to include 65", 84", 100", 120", and even a 140" version. Note; while EF discontinued the 65", there's now one offered by OMP, instead (link for *if* that size tickles your fancy).

Meanwhile, this caseSTUDY servo guide's focus is the 84" Turbo Bushmaster (aka TBM). And, yes, I know the TBM is a Legacy Aviation brand, *but* it's on EF's website and to my confused pea brain, this makes it an EF-product, so please just work with me.

Note; both the above links, as with all links within this article, open within their own browser-page. This means you won't loose where you are just because you're curious and clicked a link.

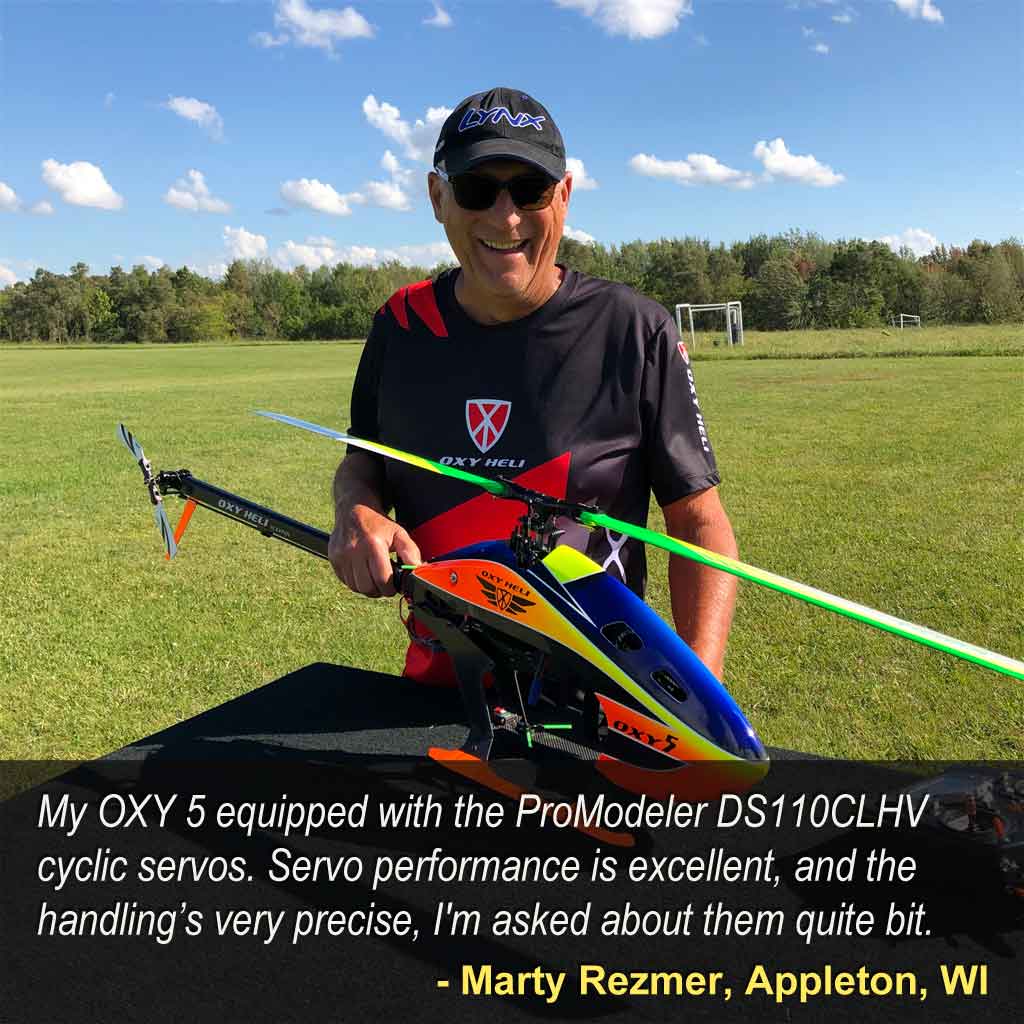

Several folks have aided me in putting this together with both photos and details of their experience. Perhaps none more so than a father daughter team of Marty Robinson and Elise, who is a mechanical engineering student at Texas A&M, who both have TBMs. This yellow 84" is hers.

- This father daughter duo is only half the story, it's *her* airplane - his is the 120 inch version

Anyway, and as usual, one of these caseSTUDY guides comes about because of customer calls inquiring about a servo recommendation. While we've sold beaucoup servos for all six sizes of this aircraft design, I own the 84" size TBM, personally. This, because I have a soft spot for 60-in class model airplanes due to their handy size.

Let me explain why this is germane with a model sporting a 40% greater wingspan, like this one.

- Low, slow, and high alpha somewhere off the beaten path within a hidden Arizona wash

Back in the day

You see, ever since I've been a modeler (+50 years), 40-60 size models have been my 'thang'. Sure, maybe I'll go off and do gliders spanning 72-160" with the local glider club, and I also love EDF and turbine jets, plus noisy TD 0.49 powered stuff spanning 24", and I especially grok giant scale models powered by gassers ranging from 50cc to 170cc, or larger, *but* somehow, the aircraft size I seemingly always gravitate back toward remains those 48-56" wingspan models powered by .40 size engines and 60-69" models powered by .61 class engines. Or similar size models with electric-power using 4S and 6S packs.In this, I suspect I'm like a lot of modelers if for no other reason than due to observations at the three different clubs I belong to.

The *why* is simple enough, it's because at this size they're no fuss, no muss models of a sufficiently compact nature they fit in whatever I'm driving (even those with an old school one-piece wing). And models with a 2-piece wing this size are a no brainer because then I can bring several without resorting to the SUV. And importantly, they've got enough size and presence to fly great even in a pretty good breeze.

Fast forward 50 years

So if you're newish to electric power, then these days nothing much has changed when using electrons instead of glow fuel. Thus, along with a 2-stroke .40 model like a Tower Hobbies Kaos, I also love packing a 52" wingspan 4S powered model like an Extra. Ditto 60" wingspan models powered by a 6S pack alongside an old school 64" pattern bird like a Bridi Dirty Bird powered by a Kraft 61. Maybe it's the same with you.

Enter the Extreme Flight 69" Turbo Raven, and Legacy 84" TBM. These make the 60"-cut

because despite the longer span, they also use the same 6S power systems spinning the same 16-17" props, which brings me to this major point . . . in the age of 2-piece wings, it turns out wingspan isn't everything! So right now our focus is the 84" Turbo Bushmaster and if you have an interest in the Extreme Flight Turbo Raven, instead, then just click the link to the TR article where we discuss servo selection for it also!

On why wingspan isn't everything

So the reason wingspan isn't everything is because just as the 65" Turbo Bushmaster, once the wing is split, it is really more akin size-wise to a 52" Extra NG in terms of the fuselage length (and because both use the same 4S power sub-system), essentially the same can be said for this 84" TBM compared to an Extreme Flight Gamebird - yes, this is a link to a Gamebird article!

As for why this is, it's because once again, the aircraft may sport an 84" wingspan, but the fuselage is practically the same length as that of many other 60-69" Extreme Flight models whether it's an Extra NG or Turbo Raven - and again, the same-same 6S power sub-system is being used. E.g. an XPWR22 or AM600, or similar, with 16x8 to 17x8 prop, plus Scorpion or T-Motor ESC. Batteries, however, may differ (more on this later). Me? I think this is Extreme Flight showing how savvy they are by respecting the modeler's inclinations. It's good business, which is why they're at the top of the game - in my opinion, which like belly buttons, we all have.

Plus, importantly (from ProModeler's viewpoint), they all use the same mini-class servos, e.g. our DS110, DS160, DS210, DS205, DS255, or DS405 line up, which range in price from $50-100.

So while the TBM sports a significantly greater wingspan than a 60" model (40% more), as it turns out, it's not really any larger in practice, meaning no more difficult to tote since the wing splits in two.

So despite being a lot larger, it's still a *very* convenient size model aircraft to transport in pretty much any car on the planet - with ease! As for the flying? This thing offers you a pure yeehaw experience!

Point being, when a customer emailed regarding a servo recommendation for his 84" TBM, because I had already spoken to quite a few folks about it, I was already rather familiar with the servo requirements. But as usual, everybody is different so the answer to what's the best servo for *your* TBM is . . . it depends. Depends on what? On you! let's delve into what may be the criteria by which you select one servo versus another.

- Colton Clark, exhibits a deft touch, hovering within the close confines of red stratified clay

Settin' the hook

For anybody's model, the right servo varies based on your preferred schedule of maneuvers (like XA-type, IMAC, sport), on your skillset (pro, journeyman, or duffer), and your budget (money is no object, buy only what I need, or I've got to be really careful with my spending because a new baby is coming). Put another way, everybody has different priorities!

Anyway, as it happened, the fellow who sent the email include a link to a private YouTube video of someone flying a TBM. Out of curiosity I clicked and holy smokes, the guy flew really smooth and had a knack for timing harsh maneuvers like crankshaft and waterfalls that rivaled some of the best I've ever seen. As for servos, he was using ProModeler, which naturally made me puff up with pride (but honestly, the guy was so good he could have been using any of our better competitor's product).

As for the video, however, a secondary effect on 'me' was it instantly enthralled me with the beautiful capabilities of this high wing model aircraft. Two things in particular reached out and grabbed me by the throat. First, when using the ailerons and flaps together to initiate a roll and then stop on a dime as if it were an NG in the hands of a top pilot! Second, when landing he deployed crow and the ailerons kicked up about 5-8° while he independently controlled the flaps. Silly thing landed super slow with about a 20' roll out. it was astonishing!

Singing the wonders of balloon tires

But want to know what really caught my attention? He was flying the model whilst equipped with 6" Kavan balloon tires and then landing on grass that wasn't manicured like a my front yard or a club flying field - more like barely pasture - and when using crow the model slowed it to a freakin' crawl that almost seemed to hover in midair.

And those big air tires did the job on the rough grass just like they do for an Alaskan bush plane. Remember, after all, this model is inspired by the turbine PT6A-27 converted Viking DHC-2T Beaver.

So talk about an all weather flier where it's large enough to handle a breeze, *and* you can use unimproved flying sites . . . wow! Point being, the video left me totally stoked for the capabilities of this aircraft.

By the way, I'm sorry for talking about it and not sharing the link but he specifically asked me *not* to share the video because the owner of the model and videographer, both ask him not to. So, naturally enough, I've honored this request (although maybe reading this article leads them to reconsider).

- These are Kavan 6" tundra inflatable bush wheels -maybe 7" would be even better!

More on settin' the hook

In fact, however, watching him fly it was kind of like when you're fishing and the bass nibbles on the bait and you haul back and set the hook. Well, just like that, his video set the hook in *me* and suddenly, I couldn't get my mind off the Turbo Bushmaster. So just like that, and completely out of the blue, one minute it was just another model, and in the next, I simply *had* to have a TBM for my own fleet.

Why? Honestly? It's because, I'm a modeler just like you and prize the superb build and quality characteristics of the Extreme Flight product. And because the TBM offers something, which to me is new, the scale look that one bush wheels or floats just looks right, catch my drift? Saying I don't see me ever using bush wheels on an NG, capisi?

Anyway, this TBM is like everything else in the EF product lineup, it's one of those models that always puts a big smile on your face (to the point your cheeks hurt on the drive home at the end of the day from smiling so much). Basically, they're all giggle makers *but* the TBM is special because you're not limited to a manicured grass flying field or asphalt (like models where you are intent on preserving the wheel pants, and which this model doesn't have, anyway). With fat tundra tires impromptu fields of opportunity become flying sites and with floats, all the waters of America are your oyster.

FYI; while rather pricey, an even larger set of 7" Airtop smooth (vintage look) inflatable balloon wheels (with ball bearings) are available from TOPMODEL CZ - direct from the Czech Republic.

Note; along with the 7" smooth Airtops, remember to order the 8mm axles, too - heads up!

Getting your model

So when the itch gets bad enough, I scratch it. How? By doing like and everybody else, I made the call, whipped out the old MasterCard, and ordered myself a TBM from Extreme Flight! Fortunately, my darling Lynn is accommodating and views me flying models as having one hobby, and me buying another model as another hobby. Yup, two separate hobbies and she doesn't complain!

Oh, and remember, I mentioned tundra type tires and floats, both, above? Well, adding more versatility is Extreme Flight (unlike most vendors) also offer float kits, too. So while I was at it, I also ordered a color-matching set of floats!

Waxing rhapsodic about float flying

As an aside, if you've never tried float flying, take it from me, it's the most fun to be had with your pants on - trust me on this if nothing else!

Flying off water is something magical for all pilots, whether the goal is lazy afternoon slow flight and setting up for landings, or maybe passing the transmitter amongst your pals. Or aiming to achieve 100 splash-and-goes, flying off water is compelling. And since this is an EF model, instead of easy, maybe you love to let it all hang out - like from the hover, bringing the rudder down to *just* dipping the rudder in the water before climbing out!

It's all about having fun.

- A pair of TBMs hovering in perfect synchronicity at Lake Lanier, GA just NE of Atlanta

By the way, while float flying is especially convenient for me because Florida has plenty of lakes to fly off of (as long as I'm watchful for gators and no, I'm not kidding), the facts are, because pretty much everywhere in the country has lakes and rivers, this means there are a lot more flying sites around than you would suspect exist. Just keep your eyes peeled, and ask around because flying with floats is a perfect change of pace!

Best part is how *easy* the crew at Extreme Flight make it for you - you merely trim a bit of covering and presto, this reveals the mounts are already built-in! Like what could be easier?

But more later about floats.

Anyway, and while I was at it, in addition to the very nicely priced set of floats, I also ordered their recommended XPWR 22cc motor, 16x8 prop (carbon), plus their ESC - everything *except* the recommended servos and servo arms because, well, duh - that's where we come into this story!

The brown truck experience

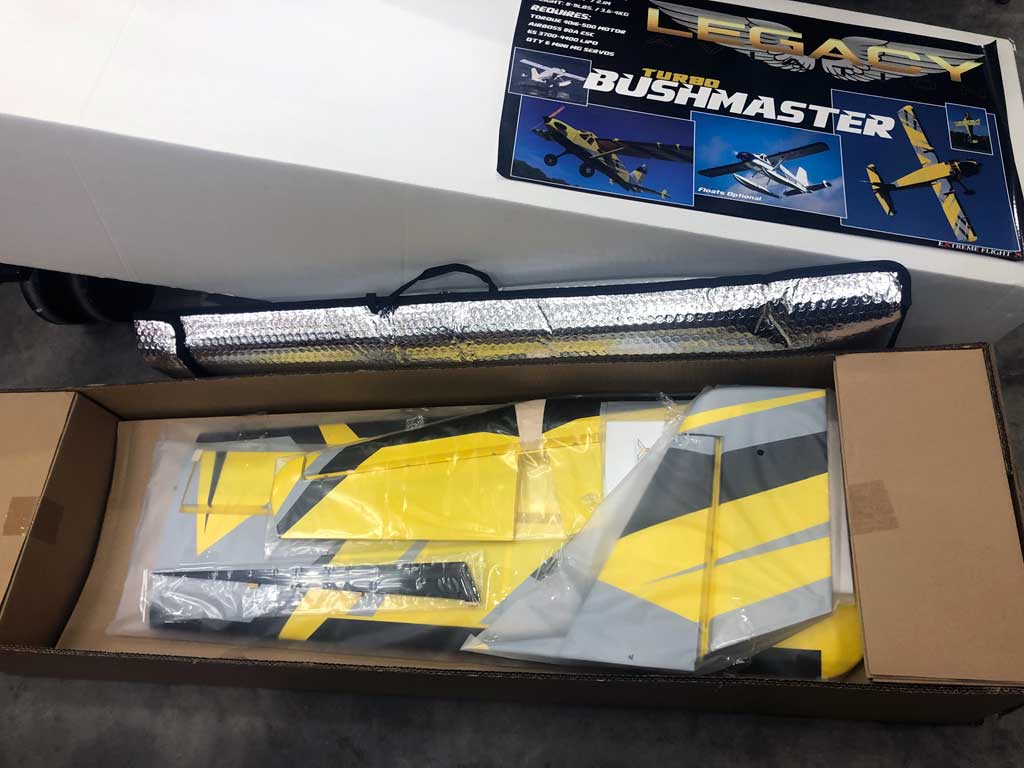

So in due course the UPS truck dropped off the shipping box. Me? Eager to tear it open to inspect, I'd given receiving a heads up so when they sent me a text it arrived, I dropped everything and hustled over to the warehouse. And let me tell you, it arrived beautifully packed, and there was no damage.

FYI, I've bought more than a dozen models from Extreme Flight and none have ever been damaged in transit. And this is no small feat. I know because I've been involved in importing a model from Asia (Audacity Models Pantera helicopter, a trainer type for learning to hover and sport fly).

Point being, there's a fair bit of package design and engineering that goes into this kind of thing, which unless you're in the business, you don't recognize. Anyway, reason these things come from half way around the world undamaged is Extreme Flight are expert at it, but I digress.

Back to the floats; they arrived via a separate shipment. And also survived the globe spanning plus brown-truck experience without a scratch - yippee! Note, as usual, the shipping-box is a typical heavy-duty D-flute brown-cardboard box while the white box (the one with the label below) is the display-box.

Due to how the display box is compartmentalized, it keeps components like fuselage, cowl, wings, stabs, gear, and hardware separate and undamaged. Everything is kept separate expressly so nothing touches, *and* a very nice touch, you even get a set of wing bags (like what you'd pony up $40 for, as an option otherwise - and they're free). Sweet!

By the way, the label shows two available colors, white with blue, and a jazzy yellow with black and silver. But they offer the model in red, also. Anyway, I selected

yellow in part because my eyes can see this color scheme better in unusual attitudes - especially at dusk, which is when I occasionally get time to fly after work.

After all, unusual attitudes is exactly what this model is for!

- Extreme Flight are such a class act they even include a set of wing bags - sweet!

Extreme Flight's servo recommendations

Since a caseSTUDY is principally about servos, then of course I took note of what they recommended. They presently offer up three suggestions for this model (although this is always subject to change). From least to most capable (or expensive), these are;

Hitec 7245MG - 89oz-in @ 0.11sec/60° - Amazon street price $77 each- Savox SV1250MGP - 111oz-in @ 0.095sec/60° = Amazon street price $69.99

- Savox SV1261MG - 277oz-in @ 0.095sec/60° - Amazon street price $93 each

- Theta THM989 - 320oz-in @ 0.07sec/60° - online street price $89.99 each

When I bought mine, they offered the Hitec. While Hitec offer a very high quality product, I felt at the time they'd be kind of light duty for the significantly larger wingspan of the TBM. After all, 84" is a 40% increase compared to a 60" model. It seems EF agree.

Thus, the lowest torque offering EF presently advise using is the 111oz-in of the SV1250MGP (about a 25% increase over the Hitec). Not sure I agree, but it's their product so I certainly won't disagree, especially because this means our $50 mini servo, the super fast DS110CLHV (110oz-in @ 0.035sec/60°) also makes the cut by their standards. And the DS110 being so speedy makes it idea for gyro use (Aura8 or AS3X). I personally love the Aura8 which a friend turned me onto.

However, in all honestly, while I'll make the case for *who* should consider such a light duty servo as the DS110CLHV, the facts are I don't actually feel many should. In fact, I think most XA-pilots (XA is extreme aerobatics) would be better served with considerably more torque. For proof, witness EF's next two recommended servos offering 277 and 320oz-in of torque. That's a lot!

So who is a candidate for our servo offerings instead of theirs? Well that's the whole point of this little discourse. Let's delve in and see if our servo selection is compelling enough to make the cut in terms of meeting *your* requirements!

- Low doesn't get any more exciting than Jeff Williams' high speed wingtip-grazing low pass

Thing is, amongst EF's offerings their minis begin at $70 (111oz-in) and then jump over $90. This leaves a gap in terms of both torque and price where we slot in three different servos (plus we offer 2 servos that are *more* powerful than the ones they offer for the same 70 bucks (for if you're in the class of pilots who need/want more torque). You know who you are.

Point being, while quite honestly, everybody doesn't need a servo like their 277 or 320oz-in, as always, it depends on who you are, how you fly, and how much money you want to throw at the model.

However, while we're being honest, when I chat with customers, many not only don't feel a need for the 270 and 320oz-in offerings EF have they don't even want our 355 or 405oz-in offerings, either.

Sure, money always comes into play and the simple fact is very few want to spend $90 for one of their servos, or our, either. Especially because this aircraft instead of needing just four servos, because it requires flap servos, also, it means you're staring down the purchase of six servos. And it all adds up, right?

Anyway, cutting to the chase. The one in bold is probably the right one for you although I selected the next one, which costs an extra 10 bucks a pop for mine because of the all-alloy case and the fact it uses a brushless motor. Don't know didly about servo motors? Review this article before deciding: About RC Servo Motors.

ProModeler's servo recommendations

So ProModeler offer six alternatives mini-class servos ranging from 110ozpin to 405oz-in and priced from $50-100. Arranged from least to most capable (and low to high price), these are;

- DS110CLHV - 110oz-in @ 0.035sec/60° - $49.99

- DS160CLHV - 160oz-in @ 0.064sec/60° - $59.99

- DS210CLHV - 210oz-in @ 0.061sec/60° - $69.99

- DS205BLHV - 205oz-in @ 0.052sec/60° - $79.99

- DS355CLHV - 355oz-in @ 0.077sec/60° - $89.99

- DS405BLHV - 405oz-in @ 0.050sec/60° - $99.99

Usually one of these articles shares thoughts regarding good, better, and best but with 6 suitable servos, it's gonna take some fine slicing and dicing to identify what's actually best for you.

And this is the major point because everybody and their brother has an opinion *but* the only opinion that really matters is yours! So let's figure out which servos suit you best based on your budget and flying style!

Note: all ProModeler servos have soft start!

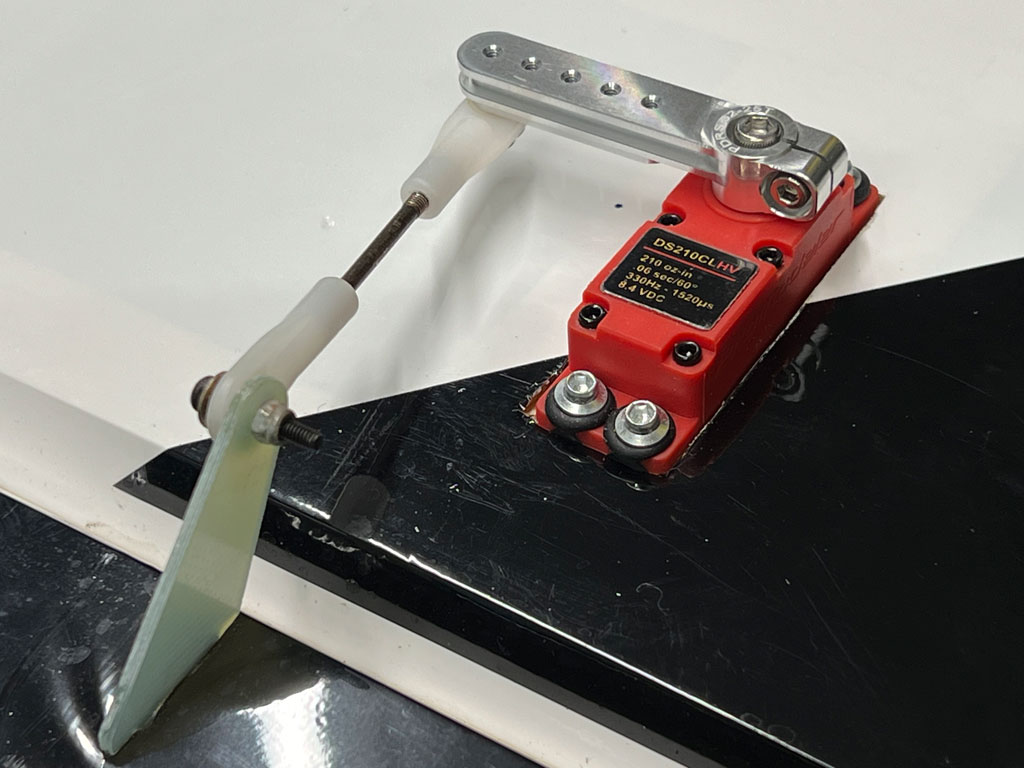

- A mixed bag; Elise Robinson's TBM sports DS160 on flaps, and DS210 on other flight controls

Back to me and my TBM. After I'd opened the box and given everything a look-see, I set aside a set of six DS205BLHV servos plus PDRS32-25T (1-1/4") servo arms along with a PDRS50PP-25T (pull-pull pulley for for the rudder instead of a tiller-type arm like PDRS40D-25T), and that's as far as I got. Sadly, I promptly got wrapped around the axle with work. Means *my* TBM remains in the on-deck circle awaiting me having time to assemble it - sigh.

Note, to the above, you'd better believe I swallowed hard when I signed the chit for the six DS205BLHV servos. They're nice but they're not cheap. And as an aside, folks assume because I run ProModeler I can just grab whatever I please from the warehouse.In point of fact, I can and do, *but* this doesn't mean they're free.

Little known fact

As it turns out, inventory control keep a close eye on me whenever I'm in the warehouse. Not that they view me as a thief, or anything but because they know I'm a thief if given half a chance. Why? It's because I have to sign for anything I take so, a) I can be billed, and b) so the inventory stays straight.

Billed? Yup, means I don't get them for free *and* what's more, not only do I pay for servos just as you would if you visited the warehouse and got some *but* I pay the exact same price!

Anyway, while I regretfully put the model away for later, because I own about a dozen of Extreme Flight's models, I'm not exactly lacking for a good handling aircraft to fly. So while it's unfortunate I haven't found the time to assemble my personal TBM, it's not the end of the world, either.

So where am I going with this? Well, naturally, into a servo discussion for the 84" Turbo Bushmaster because I may feel the DS205BLHV is the best servo for me *but* this doesn't make it the best servo for you!

And by the way, not having time to get my TBM together doesn't mean I haven't had a chance to fly one because they're very popular (actually, it seems they're everywhere). Moreover, because we've had loads of guys reach out to us for a set of servos since they released the model, what I have to say (over and over again) has gotten a bit repetitive.

So it's really *past* time for me to put together this TBM caseSTUDY to help guide folks without your having to a) wait on reaching me by phone, or b) using email to pick my brain. Win-win!

Anyway, while I decided on the DS205BLHV servos for mine, that doesn't mean they're the right servo for you. So let me share how I guide folks because in truth, the DS205BLHV is a somewhat pricey servo ($80), and I recognize such expensive brushless servos won't be everybody's cup of tea.

That, and what a decent sport pilot like me, versus an accomplished IMAC-type (precision aerobatic, or pattern) pilot, versus a non-precision XA pilot (XA being extreme aerobatics), versus the guy who is the 2nd coming of Jase Dusia, versus a duffer *needs* are all different things.

Point being, there's a *reason* we offer you six mini-class servo alternatives!

Considerations

In point of fact, while the 84" Turbo Bushmaster uses the same power package as their 60" models, the servo selection is going to be different than for a 60" model. Heads up if you figure to repurpose mini servos from that 60" Extra you recently stuffed. Why?

It's because what works perfectly for a 60" really won't necessarily be so good for the task of horsing around an 84" span model like this TBM because there's a bunch of added aerodynamic leverage acting on the servo. This, because you're dealing with a couple more *feet* of wingspan. Basically, don't expect the servo that works nicely on a 60" to handle the larger wingspan model with the same ease.

There's a reason for this caveat, and it's not just coming from me because you'll note EF offer you three servos, two of which are *much* more powerful than those typically used for a 60" model. These being one offering you 277oz-in and another offering you 320oz-in of grunt.

Anyway, let me begin by explaining the case to be made for our least expensive mini-class servo, the $50 each DS110CLHV.

DS110CLHV - $50 each X6 = $300

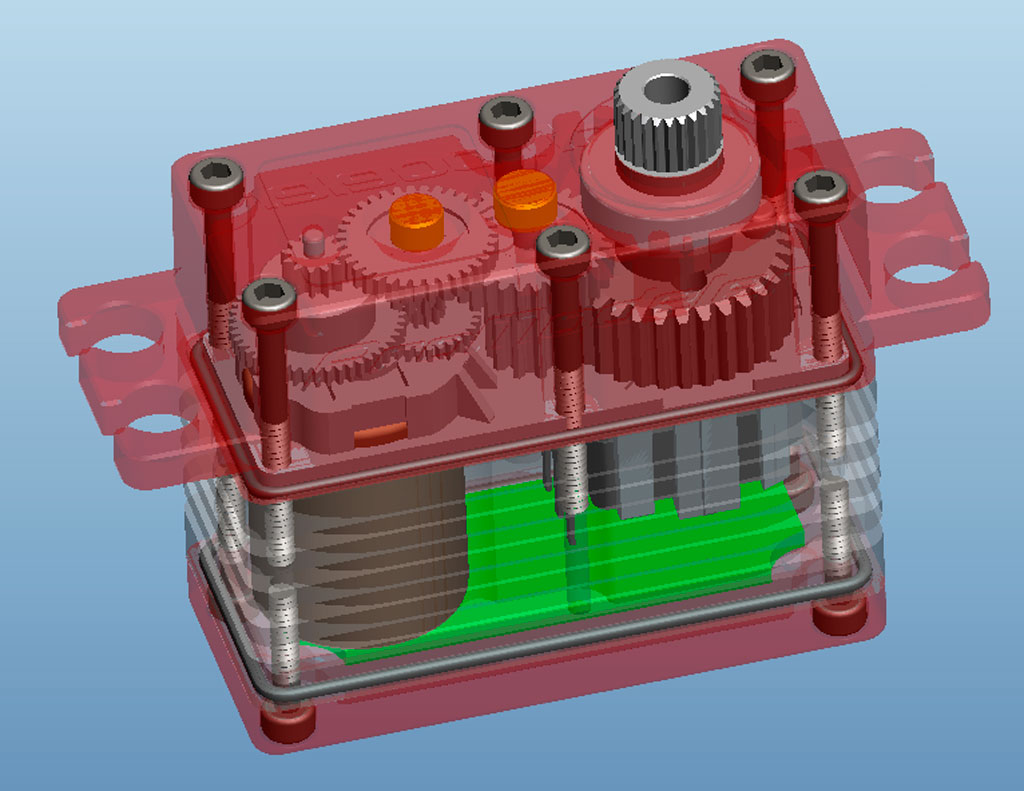

First up is the DS110CLHV. And this 110oz-in mini transits in a blistering 0.035sec/60° and is quite special *but* before we get ass deep in servo nomenclature, let me clue you in on what the ProModeler servo-code is because it's so easy you don't need a decoder ring to suss it out.

- DS = Digital Servo

- 110 = torque rating in oz-in

- CL = Coreless motor (and we have BL, or brushless and the$e are 'mo betta)

- HV = High Voltage (to 8.4V)

Anyway, the DS110CLHV was initially developed for a defense contractor with a gyro controlled UAS. Their big demand on us was speed because of their use of gyros. So once it came off contract and became available to civilian sales, it was immediately taken up by pilots of 500-class helicopters because helis use 3-axis gyros and for 3D maneuvers, servo-speed is king!

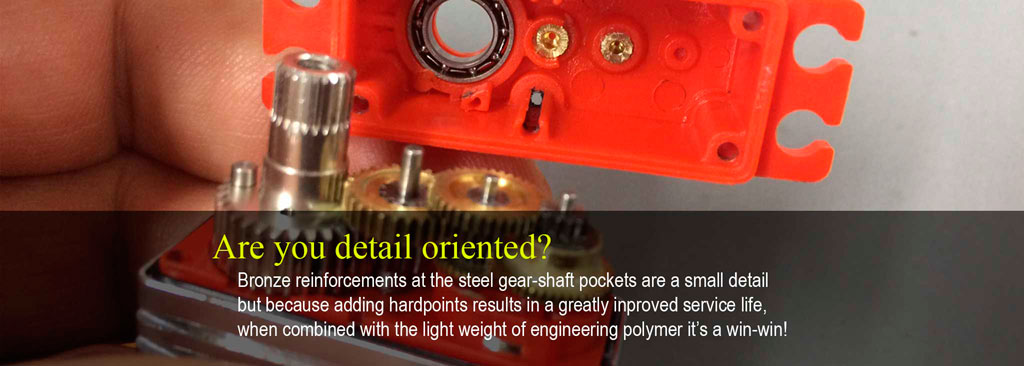

The construction of the DS110CLHV is shared with the other two in the class, the DS160CLHV and DS210CLHV. All three offer lightweight construction featuring polymer upper and aluminum centers. We bush the case at high stress locations with bronze inserts (where the steel gear shafts are fitted). This gives you the durability of an alloy case (one that's actually better than servos where the steel shafts are fitted directly in the aluminum because bronze is harder than aluminum).

- Molded Swiss-turned SAE65 bronze bushings create hardpoints in the plastic for gear shafts

But while the DS110CLHV is fine in a 60" model, it's really not enough for the 84" TBM in my opinion. Just not enough grunt. Maybe if you're into slow maneuver 3D pilot who torque rolls, does rolling Harriers, but never maneuvers that require lots of torque like a crankshaft, waterfall, or rifle roll. Otherwise, trust me and step up to our next in class, the DS160CLHV.

So, my first actual servo recommendation for the TBM is the ProModeler DS160CLHV.

- The render lets you use Superman-like X-ray vision to see the guts of an assembled CLS-mini

DS160CLHV - $60 each X6 = $360

So I'll begin by noting we developed the DS160CLHV servo in 2016. Again for a defense contractor. Off contract in 2017 it immediately found a home in 60-class 3D-airframes. Between the speedy DS110CLHV and the more powerful DS160, amongst pilots of 60" class 3D models these two minis feasted on our competitors in the marketplace.

And while the DS110 is way the hell faster, the DS160 is no slouch at 0.064sec/60° - all whilst being quite a bit stronger. This is because that's the typical tradeoff (strength for speed and vice versa). So with a 45% increase in rated torque, and equipped with all-steel gears, both are immensely durable.

But of the two, the DS160 is hands down the most popular choice for 60" class models. When you're shopping around, the *why* is obvious, price plays a huge roll. Not just built better than competitors but at just $60 a pop, price has a lot to do with it (or so I suspect). And given the genuine Japanese Nobel 1mc potentiometer the centering is excellent.

The mini-class servos with all-steel gear trains (all of ours) stay tight and last a long, long time.

And in truth, while the D160 remains a great servo for 60" 3D aircraft, for larger models like TBM or Turbo Raven? Honestly? Once upon a time we would usually guide folks to more powerful servo, like our DS205BLHV, instead. Why? Because of the heaviest component of the model, the propulsion pack.

Batteries

In a word, the reason for using the more powerful servo had to do with the batteries. It's because the power system may be similar, but instead of a 6S3300 weighing maybe 500g, folks often equip the Turbo Raven with a 6S4000 massing 620g. An extra 120g is not zero.

With a 60" model the extra 120g may be a big deal (depends on the pilot's capabilities, of course, some pilots can't even notice the added weight) but with models like TR (and TBM), the added wing area of the 69" wingspan vs 60" wingspan means a lower wing loading even with the heavier pack so the model handles the added mass with grace. In fact, an accomplished 3D pilot in my club is a proponent of using an 8S pack! But for a 60" model, 200oz-in is a luxury reserved for pilots who fly hard. So where do we get into more servo needed for a heavier model?

More mass needs a more powerful servo

And it's not just the TR, but this is true for the TBM, too. Quite frankly, it's not uncommon for TBM-folks who run the wing-loading numbers to opt for a 750g 6S5000 pack. Then, if you add for the larger tundra tires, and/or maybe floats and the *why* for more powerful servos begins to resolve itself. You need more power to accelerate the initial entry into the maneuver because the mass has to be moved and forced to respond to the command and it's the servo acting against airflow that does the moving. Stands to reason once you think about it, right?

However, beyond more mass, add to it the longer wingspan, which means ailerons have more leverage. Leverage is imposed over the servos by the air flow, too (meaning the amount of force the force of the air can feed *back* into the servos as airspeed builds).

Think back a minute to when you were a kid and stuck you hand out the window at 60mph. Lot more force than when Dad was driving 20mph, right? Same thing with our models, the air is pressing back against the servo. And the faster you fly the model, the more it presses back hence, when you fly a maneuver like a Rifle Roll, where you're flying WFO and then deflect the ailerons to the max, you need servos with cojones! So the recommended minimum servo if the budget could handle it for a 69" model like the Turbo Raven was the

DS205BLHV. Ditto the 84" Turbo Bushmaster. Only fly in the ointment for most folks is this is an $80 servo. So most guys simply shy away from spending that much dough.

And *this* explains is why EF offer these two servos;

- Savox SV1261MG - 277oz-in @ 0.095sec/60° - Amazon street price $93 each

- Theta THM989 - 320oz-in @ 0.07sec/60° - online street price $89.99 each

. . . and back to ProModeler servos (since obviously, these are pricey servos for many folks).

Recapping

So almost by default, nearly everybody opted for the DS160CLHV, a $60 servo for their 60-69" model instead of the $80 all-alloy brushless servo 205oz-in. So while the DS205BLHV is a considerable step up in terms of what you get (all-alloy case and brushless motor), the bottom line is it's simply to expensive for a lot of folks. And if $80 is too much to bear, then the above two servos are also, agreed?

And note; if you're a journeyman 3D pilot (not in the class with a Dussia-type), then I *really* can't fault you either because you may not even be able to tell the difference at this point in arc of your development. Basically, the DS160 is plenty good enough if you can't feel the difference due to your flying style.

But what if you want a more powerful set of servos? Maybe because you have plans to work the simulator and get better!

Background

A recent development of the CLS series (DS110/160/210CLHV) is we upgraded the gear train from all-metal to all-steel. Steel being a tougher metal makes for a more durable servo so the precision fit lasts several times longer than before (and compared to other brands). Proof steel is the best for gear trains doesn't even require you to be an materials engineer. You just need a set of eyeballs Mk II.

Guess what gear material is found in the transmissions of Ferrari Formula 1 race cars? Remember, they're the race cars of the money-is-no-object crowd where just one wheel hub, not the freaking wheel, just the hub, cost $10,000. They're equipped with transmissions using, ta-da, all-steel gears! Ditto when you attend a NASCAR event, all these significantly heavier race cars once again (in a sport where no poor people are fielding a car) havetransmissions using all-steel gears, as well.

Wanna know what you won't find in either? Titanium, that wonder material beloved by marketing types because it makes rubes reflexively reach for their wallets. Engineers? Engineers know titanium is a bullshit material choice for gears. And other than amongst those influencing hobbyists, now you know why. Steel is better. My point?

Cast your eyes on this beauty, the new all steel gear train of the CLS series servos. Best part, we held the line on pricing because we've come a long way from where we started. In short, we've gained market share, and this translate into clout.

Means now we can actually negotiate with our suppliers and not be on the back foot due to buying small volumes! And since we offer the servo with the new all-steel gear train at the same price, guess who wins? You!

Guess who hates our guts for doing it? Yup, the usual suspects amongst our competitors!

- ProModeler DS110/160/210CLHV now features a tougher, more durable, all-steel gear train

So here's the story of the all-steel gears. My motor supplier rang me up one day and said, I got something new for you. This turned out to be a motor that would let the DS160 make 210oz-in and critically, not only that but gain a tick in the speed department whilst doing it. Hmmm!

Magnets are the magic

Modern servos are a product of neodymium magnets. They're what's at the heart of these wonder servos making so much torque. Thing is, we knew we'd hit the limit of our all-metal gear train with the 160oz-in DS160CLHV servo. It's why for the DS205BLHV we went to an all-steel gear train.

Thing is, stuffing the new faster and more powerful motor in the same-same case as the DS160 to create the DS210CLHV meant we'd see folks breaking the gears in the air due to the heavy loads being imposed. However, if we switched to all-steel gears, then we could offer it at a price point between the existing DS160 and the DS205 and instantly gain access to modelers who just couldn't justify an extra 20 bucks per servo but for whom an extra tenner was doable.

Best part of all this, making the DS210 work was pretty simple, except, to hold up, we also needed to redesign the upper case. In this, we added a little bit more polymer surrounding the bearing to better anchor it for the anticipated loads. So we redesigned the upper case, which is why it looks different.

So now we offer you the DS210CLHV instead of the DS205BLHV as the next step. Best part about this servo, at just another tenner, it slots in perfectly between the DS160CLHV costing $60 and the DS205BLHV costing $80 at the midpoint of $70. Bingo!

- Elise Robinson, her 84" Turbo Bushmaster, Ice House Fly-In Apache Pass, Rockdale, TX

DS210CLHV - $70 X6 = $420

So our first choice for budget minded pilots would actually be the DS210CLHV, instead of what once our best alternative, the DS160CLHV. Not only priced at just 70 bucks, they transit in the same 0.06sec/60° as the DS160 - while costing just an extra ten bucks.

Basically the DS210 is the same servo as the upgraded to stainless DS160 with a 30% stronger motor. So this servo would be my first recommendation for your 84" Turbo Bushmaster over either the DS110 or DS160 just because as models get larger and heavier, there's no substitute for more torque. Torque is what let's the model perform the maneuvers you want to perform.

So why, knowing the DS210CLHV was coming did I nevertheless opt for the pricier DS205BLHV for my own model? Simple, with the DS205 I get a brushless motor (more betta') and an all-alloy case (mo betta' again).

By the way, the all-alloy case of the DS205 makes it more rigid than the DS210, a big plus with 3D airplanes. Added to which, the DS205 is faster than the DS210, another plus. The alloy case also means it's more durable where the bearing fits the case as it never wears the way a plastic case servo does eventually. But these also cost more - can't be helped. So because they go for 80 bucks a pop, and most guys don't want to spend this much for a mini-class servo, then the DS120 is a nice addition to our lineup (and we probably produce more mini-class servos than anyone else in the business).

Meanwhile, Extreme Flight actually recommend yet a *more* powerful servo than our DS205 or DS210 in the form of the Savox SV1261MG (277oz-in) and the Theta 989 (320oz-in). Why? In a word, leverage. Why does this matter? Well, leverage, matters a lot, let me explain.

Leverage

Look, there's a reason my first instinct servo-wise was to grab a set of DS205 servos. This is because I am a good pilot but not a gifted pilot. So my 50 years of experience informed me the DS160 wouldn't be enough servo for the significantly longer wingspan of the 84" Turbo Bushmaster when flown hard. At the time the DS210 didn't exist so I opted for DS205. And this makes sense when you think about it because why else do you buy an Extreme Flight aircraft but to fly it hard? However, if I really flew hard 3D (different from just flying hard like i do) then I would have grabbed a set of DS355. And these days, maybe even a set of our DS405 mini class servos, instead!

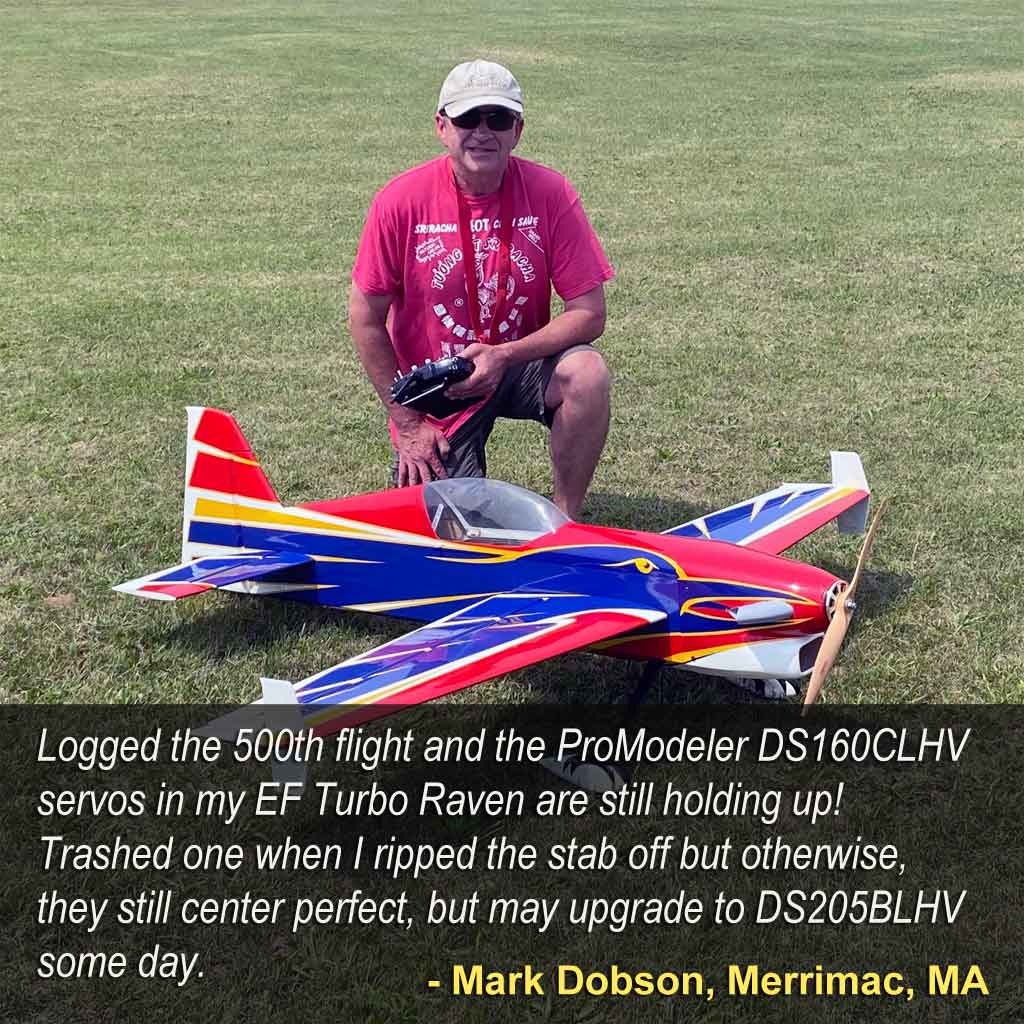

So yes, DS160CLHV have been perfectly fine with any 60" Extra on the planet (60" put another way, is a model with a five foot wingspan). The DS160 are even strong enough for most pilots with the Turbo Raven (69"), witness the above photo. But this is a model sporting a nearly 6 foot wingspan (or nearly 20% more leverage than a 60") so the TR definitely deserves a more powerful servo if flown hard, and much more powerful if flown in hard 3D.

But the 84" Turbo Bushmaster? This is a *seven* foot wingspan model aircraft (or 40% more leverage versus a 60" model). So I think because there's a Hell of a lot more leverage with both of these compared to a 60", there are better ideas servo-wise than our DS160 because of the added leverage.

And there's the word again, leverage. What it comes down to is when you're muscling the model around you need a lot of torque to overcome the leverage of the longer wingspan. This is why Extreme Flight offer you a 277oz-in and a 320oz-in servo as better alternatives for the TBM.

- Muscling the model like this down low takes a lot from both the pilot and the servo

So the original DS160 works very well in 60" class 3D models. And the DS205 was previously our all-out recommendation for a hot dog pilot of a 60" but the DS210CLHV changed the calculus because now you could afford more torque and not break the bank. So who wants the DS205BLHV instead of the DS210CLHV? Let's discuss this servo briefly.

DS205BLHV - $80 X6 = $480

In a word, the guy who wants the best money can buy prefers the brushless motor and alloy case of the DS205 to the DS210. With the DS205BLHV you also get all steel gears but all all-alloy case and brushless motor are nice upgrades durability wise.

Brushless motors not only run cooler but also last 5X longer. You don't care? I understand but I come from a school of thought that says buy once, cry once.

Don't know didly about servo motors? Review this;

Anyway, until you've held a DS205BLHV in your hand you can't understand the sheer beauty in a perfect mechanical design. It's an engineer kind of thing. A hot rodder understands, so do others with an affinity for metal like machinists, plus tool & die makers. So if you don't grok this, I totally understand because the DS205 isn't for everybody.

Me? I had no problem peeling off three extra double saw bucks for the DS205BLHV versus DS160CLHV. But yes, some of you will balk, and I get it. But some of you won't and it's for you whom we produce this servo!

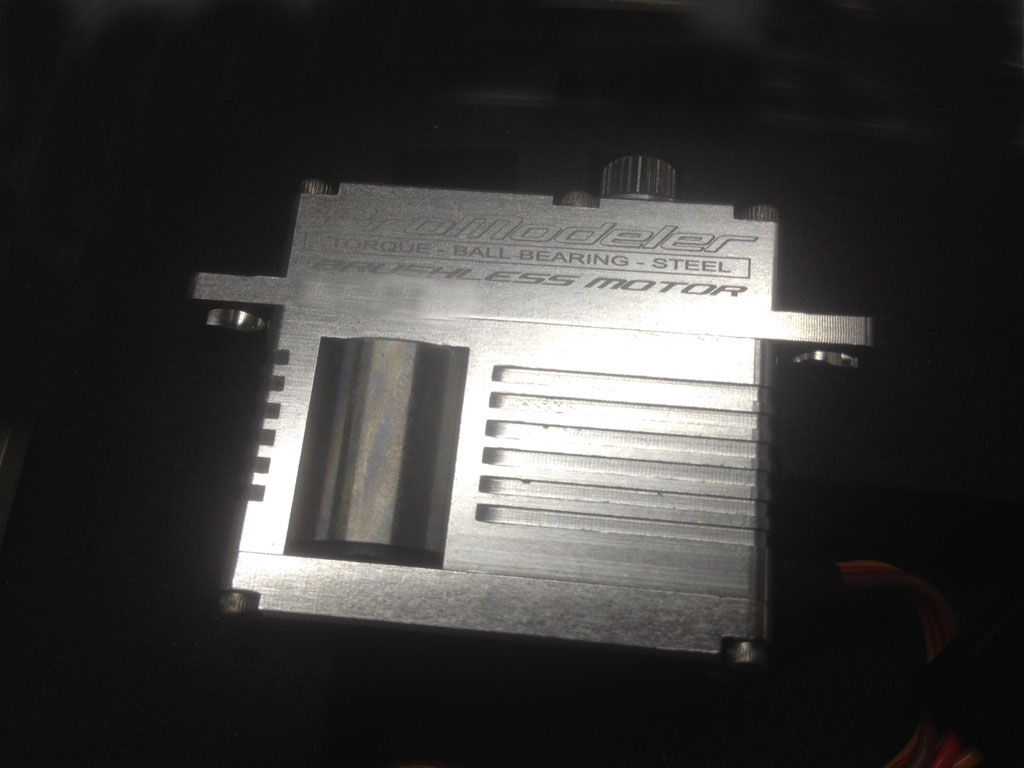

- The alloy-case DS205BLHV has brushless motor, all-steel gears, and transits in 0.052sec/60°

Recapping

So to be honest, in the 84" TBM, the DS210 is enough servo for all but the most brutal of pilots. In fact, for a lot of pilots, the DS160 is perfectly OK also because (and this is important), a lot of folks love how the Turbo Bushmaster looks and flies *but* aren't really into hard core 3D. After all there are a range of maneuvers considered 3D fomr relatively easy to perform like torque rolls, to ones demanding all the servo will give like Rifle Rolls, Crankshafts, Waterfalls, etc.

The right servo for you, depends on you!

Also, while it's our opinion, the DS160 is GREAT for a 60" airframe, and quite decent with a 69" wingspan model like the Turbo Raven (or 67" Skywing models), it's a case of not quite enough for the 84" span Turbo Bushmaster, in our opinion. Especially if you're an accomplished hard-flying 3D pilot (lie Dussia).

Thus, while we guide most folks toward the DS210CLHV - at a minimum - everybody doesn't agree. EF, for example, are guiding hard flying TBM pilots to servos outputting 277oz-in and 320oz-in. We do, too, and this is where our DS355CLHV and DS405BLHV enter the picture.

Note; it's my further opinion while the DS210CLHV threads a needle in terms of price/performance (the perfect servo for probably 90% of pilots), for the pilot good enough to tell the difference, the brushless DS205BLHV is 15% quicker at 0.052sec/60°so while it's not for everybody, the more discerning (and better heeled) usually opt for the

DS205BLHV instead of the DS210CLHV.

So for whom are the DS355CLHV and DS405BLHV for? Very simple. They are for the more aggressive. The harder you fly, the more you appreciate the servos EF is guiding you toward, the 277oz-in Savox 1260MG and 320oz-in Theta THM989 for this model. And if you are good enough to appreciate those, then I believe you'll appreciate ours, too. And not just for the difference in price for what you get, but for the generally superior build quality of our product. Big words? Stand by, we prove it. Patience.

Fly in the ointment

Problem is, for both Extreme Flight and ProModeler, . . . is very few pilots agree such a powerful mini makes sense for them. Since EF don't have a decent 200oz-in in their lineup (yet), this creates an opening for ProModeler.

Their offerings go from . . .

- Savox SV1250MGP - 111oz-in @ 0.095sec/60° = Amazon street price $69.99

- Savox SV1261MG - 277oz-in @ 0.095sec/60° - Amazon street price $93 each

- Theta THM989 - 320oz-in @ 0.07sec/60° - online street price $89.99 each

. . . and where for the same $70 we offer you DS210CLHV (210oz-in 0.06sec/60°)

But while their Savox SV1261MG offers 277oz-in at 0.095sec/60° for $93, we offer you . . .

- DS355CLHV - 355oz-in @ 0.077sec/60° - $89.99 (stronger and faster, for $3 less)

- DS405BLHV - 405oz-in @ 0.050sec/60° - $99.99 (stronger and faster for $7 more

. . . so the DS355 outperforms the SV1261MG by a wide margin for less money, the Theta is offered for the same money as the DS355CLHV, but is slower and not quite as strong. However, we also offer you one both stronger and MUCH faster in the DS405BLHV.

So why it many resist +320oz-in Theta would they be interested in our 355oz-in servs? Mostly, I believe, it's because they've never experienced what this class of servo has to offer when the wingspan is 40% larger than what they're used to. More powerful servos are what's needed to overcome the extra leverage. And our 355oz-in and 405oz-in servos deliver in spades! Thus, the reason many aren't interested in more powerful servos (presuming they can afford them is they either don't need them because they don't fly hard, or if they do, then they have never experienced what this class of servo brings in terms of letting them up their game. It's basically a lack of perspective the best pilots may have due to not having ever experienced it.

And when I say best, I mean those experimenting with new stuff. The ones actually inventing the maneuvers other pilots eventually begin to copy. After all, someone was first with the Waterfall, right?

Meanwhile, most folks end up refusing to believe me when I say it'll matter. This, even when Extreme Flight themselves are guiding folks to their 277oz-in and 320oz-in offerings, also. It's a conundrum and seemingly can't be helped. In short, it's a nut I haven't managed to crack yet. And I'm not convinced it's just the extra 10 bucks per servo preventing them from making the jump into that 300-400oz-in class of minis.

But some have . . . witness this fellow. He totally groks what super minis offer.

I suspect, over time, as higher caliber pilots allow pals who are pretty good sticks to fly their 300-400oz-in equipped models, when they get to feel for themselves the difference in certain maneuvers (think Rifle Roll, or Wall where there's a huge advantage of flying servos with stump pulling torque sufficient to jam the control surface out in the breeze at high speed at speeds that overwhelm 200oz-in servos), then regular 3D-pilots will eventually come around.

In fact, sport pilots typically ask about using our DS110CLHV, instead of the DS160, much less the DS210. Why? In my opinion it's 100% because these costs less than the DS160CLHV.

Meanwhile, the least expensive offering on the EF website (at the time of this writing) is the nice Savox SV1250MGP plus the very nice but even more expensive (and very nicely made), SV1261MG followed by the Theta THM989, all three of which - straight up - offer us solid competition.

- DS160CLHV used for the Turbo Bushmaster flaps, here fully deployed

Servo recommendations, specs and pricing

So reviewing EF's mini-servo offerings, specs, and street pricing to see what we can learn;

Hitec 7245MG - 89oz-in @ 0.11sec/60° - Amazon street price $77 each- Savox SV1250MGP - 111oz-in @ 0.095sec/60° = Amazon street price $69.99

- Savox SV1261MG - 277oz-in @ 0.095sec/60° - Amazon street price $93 each

- Theta THM989 - 320oz-in @ 0.07sec/60° - online street price $89.99 each

To reiterate, I try to guide folks away from the DS110CLHV for a tBM because I don't feel a Century-class servo is enough (although we *do* have some pilots flying the TR with our DS110CLHV and they're happy).

But to my knowledge, we don't know of any flying the TBM with DS110. So we don't recommend the DS110 for probably for the same reason EF stopped offering the Hitec HS-7450MH. It's because nether of these servos are strong enough, in my opinion, to *really* force the control surface as far out into the breeze as needed for good 3D performance. Not against the leverage afforded by an 84" wingspan model (against so called blow back).

- Electing to use the PDRS40D-25T for the pull-pull rudder and a connection to the tail wheel

So cutting to the chase, let me tell you who killed Cock Robin. ProModeler offer six servos that will fit the Extreme Flight 84" Turbo bushmaster air frame;

- DS110CLHV - 110oz-in @ 0.035sec/60° - $49.00 each

- DS160CLHV - 160oz-in @ 0.064sec/60° - $59.99 each

- DS210CLHV - 210oz-in @ 0.061sec/60° - $69.99 each

- DS205BLHV - 205oz-in @ 0.052sec/60° - $79.99 each

- DS355CLHV - 355oz-in @ 0.077sec/60° - $89.99 each

- DS405BLHV - 405oz-in @ 0.050sec/60° - $99.99 each

We've touched on the DS110CLHV, DS160CLHV, DS210CLHV, and DS205BLHV. Next, let's go beyond what EF offer you (277oz-in and 320oz-in), to our DS355CLHV and DS405BLHV offering up a stunning 355oz-in and 405oz-in respectively!

- DS210CLHV equipped with PDRS32-25T servo arm (1-1/4", 5-positions) on ailerons

So how do we define hard 3D, or XA?

It's like this; if you are performing Rifle Rolls (wide open throttle and full aileron deflection), a maneuver which is *really* hard on aileron servos and which not all 3D pilots can pull off, then you need more than the DS210 offers (or the DS205). This is probably why EF guide top pilots to the 277oz-in and 320oz-in servos (our assumption being, those who are less than top pilots don't need to be expressly told).

Ditto if your repertoire Include the violent Crankshaft maneuver (rough on everything), and Wall maneuver (especially hard on elevator servos because it presents the entire bottom of the airplane to the forces of the wind). Similarly, if you fly the Parachutes, another maneuver tough on elevator servos. If you so, then you stand apart from most 3D pilots. Quite honestly, you are in a rather select group of what I call XA-pilots (Extreme Aerobatics).

Look, I don't know you, and have never seen you fly so I can't judge based on what you say on the phone - only you can make this decision. But trust me, if you perform the above maneuvers, then you really, really want more than 160oz-in or even 210oz-in. You probably want more than 277oz-in or 320oz-in, also.

DS355CLHV - $90 X6 = $540

So what's next? Well, since Extreme Flight deem it worthy of offering the 277oz-in @ 0.09sec/60° SV1261MG, then it's worth noting for similar money you can buy the DS355CLHV, instead. Ours at 355oz-in is 28% more powerful and costs about the same. That this is a lot of money is true, we get it *but* it's built significantly better than the Savox, too. Why? Steel gears, hardpoints in the case, cooling fins, and it meets two MIL-STDS for vibration and shock.

The hardpoints within the case (at the gear shaft mounts) are there expressly to ensure the servo will actually *live* when making that kind of torque. After all, once you get into the mid-300oz-in, a mini servo experiences forces that pound the steel gear shafts against the aluminum of the case so forcefully it distorts. Happens with ours at 205oz-in and I bet it happens at 277oz-in also. Let me tell you, the bores wouldn't hold up in our servos so we reinforced them, what makes you think they hold up any better in theirs?

So I predict they won't stay round - they'll go egg shape in time - and it doesn't take long when you abuse the model *unless* the case is reinforced. We do, they don't. It's your money but it reminds me of the old saw, 'choose wisely'. Especially as once the bores go egg shaped, then the tolerance of the gear mesh goes to Hell and they begin to wear like crazy. Fact!

But beyond that, the SV1261MG lacks cooling fins and if you think you can run a few amps through that servo and not shed heat efficiently you're in for a surprise. And the servos in a 3D model are constantly moving so they get hot. ProModeler? We mill cooling fins into our servos for the purpose of effectively shedding heat, not for decoration! Heads up. This costs more to do *yet* theirs sells for a similar price as ours. No cooing fins, no hardpoints, no MIL-STDS, less torque, and a touch slower but similar price? Go figure!

Plus with ours, you get all-steel gears, which are way the hell stronger than whatever they're using. Then there's the Theta THM989 . . . instead of fins they use the space on the side of the case for a lasered logo - sigh. As for the gears, they don't say.

- Turbo Bushmaster's direct elevator linkage gives you tight control

DS405BLHV - $100 X6 = $600

So who should pony up for our DS405BLHV servos? Maybe nobody. Or maybe those of you who are out there actually inventing new maneuvers! Why? Well, if you fly really hard, then the +400oz-in being output by the DS405BLHV absolutely WILL shove that aileron out into the breeze with the authority, which a 277 or 320oz (or even our 355oz-in servo) just won't.

Is this reason enough to pay $10 more than the Theta? We think so, especially in light of how much better made it is than that Asian import. But we dunno, it's *your* call, but if you shop around, an extra $10 is not very much more dough for what is a clearly better made product.

That, and when the DS405BLHV is working hard, because it's so very, very much powerful, it'll be loafing compared to their more heavily stressed servos. There's a school of thought that values overkill and the DS405BLHV is the very *definition* of overkill.

A few last thoughts before wrapping this up . . . what 'really' differentiates a ProModeler servo from the competitors? Meaning, what makes the DS110/160/210 series better is unlike hobby-grade servos, they're built to meet military standards (and subjected to these tests).

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Water intrusion - Test Method 514.5

In part, this is due to the requirements of our primary customer. However, because we're modelers and have knocked a servo off a workbench, experienced crashes, and know a thing or two about vibration (plus how a summer afternoon pop-up rain shower may drench a model before landing), it means these tests are important for civilian users (modelers).

Floats, Extreme Flight, water resistant ProModeler servos, and you

Earlier, I mentioned Extreme Flight offering floats for many, many, of their models, the TBM included. This is a large part of what made me such an enthusiastic supporter of their company (I love float flying).

And obviously, other pilots must agree because these guys (EF) aren't exactly stupid, else why do they offer so many float kits if someone isn't buying them? Enough so, they're easily the market leader. In short, in addition to world class 3D models, they offer world class float kits and make it very easy to do.

This is basically what you get - prefabbed FRP floats (FRP means Fiber Reinforced Plastic, aka fiberglass). So pre-painted floats of a caliber to rival their cowls, and to include struts, sub-fin for the fuselage (to compensate for added side area forward of the CG), plus all the required hardware. And it's all top shelf stuff!

Point being, if you're looking at another servo, one which offers similar performance and pricing but hasn't been tested to military standards, to include - ahem - resistance to water intrusion, then if you've never considered float flying, here's another reason servos meeting MIL-STDS are better for you (even if you don't feel you need the benefit ProModeler's enhanced durability due to all-steel gears, hardpoints in the case, potting compound on the PCB deliver right now).

However, beyond making servos expressly designed to survive the abuse encountered in the real world, there are important ownership considerations worth mentioning with a ProModeler CL-series servo.

For example, when I mention hardpoints, many are surprised to learn this means there are bronze inserts within the polymer case. These, for reinforcing where the steel gear shaft fit. With the CLS-series, this makes for a twofer, e.g. the benefit of lighter weight with the durability of an alloy case!

Also, do you consider your servos to represent an investment? If so, then ProModeler servos are worth your consideration not just because they outperform the others, but because they're built to last longer. And the thrifty amongst us will especially recognize what receiving good value means in addition to receiving top level performance. Honestly, in this regard, it's well recognized your ProModeler servos really deliver, and here's why.

First, many modelers immediately notice the cooling fins machined into the case. All else being equal, cooler components last longer, right? But beyond this, even if you're not an electrical engineer, you'll appreciate other small touches - ones which are otherwise invisible. We refer to our 10-bolt assembly as the porcupine case - can you guess why?

- Compared to smooth-side or plastic-cases, alloy cooling fins deliver longer component life

Second, there's the matter of the 13 o-rings which seal the case. They're between individual case components, and at the output spline shaft, and beneath the heads of the ten grade 12.9 Allen head screws (used to secure the three servos in the CL-series together). And as noted above with the porcupine case, these thread into aluminum instead of plastic!

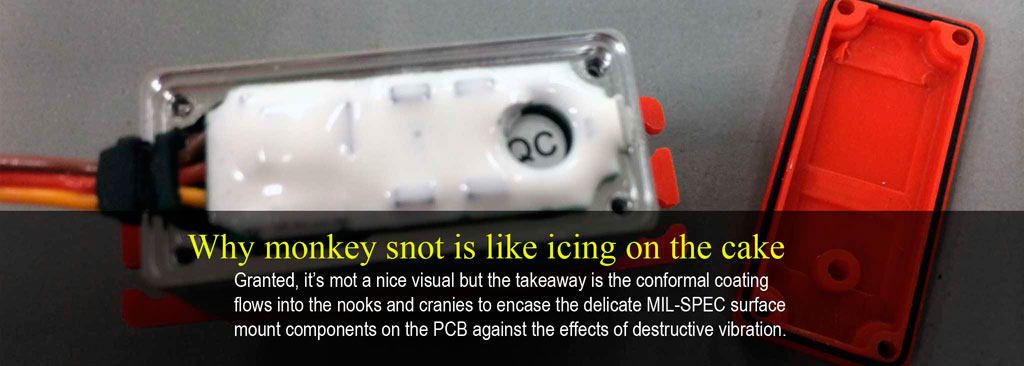

Third, there's how we protect the PCB from vibration with a conformal coating (instead of a cheapo square of foam rubber). Also referred to as potting compound in the civilian world, we just call it monkey-snot. Why? It's because it's such a sticky smelly mess to apply. But totally worth it!

So why do we bother applying monkey snot? Simple, it's because once applied to the PCB, it oozes between components and sets. This is the secret sauce behind our servos thriving in harsh high-vibration environments. Bottom line? This is an aerospace-grade technique, and one which also help makes ProModeler servos more valuable to you by prolonging service life.

After all, while they're destined for an electric model right now, who is to say - perhaps a few years from now - you don't choose to race high vibration Formula 1 model, or perhaps are attracted to helicopters, or even high performance turbine powered models? Thus, since you can't predict your future interests, maybe instead of focusing on just one thing when making your servo selection, you'll bear in mind how your investment in ProModeler servos versatile enough for wherever your heart may some day lead you, means you're also being a good steward of your financial resources. After all, money doesn't grow on trees, right?

So beyond performance, ProModeler is really about delivering good value!

Summary

When building a world class 3D model aircraft from the likes of Extreme Flight, then ProModeler offer you six really solid servo alternatives for customizing your experience. Fast for gyros, powerful for the aggression, and both! At great prices.

These range from the stupid fast DS110CLHV, which is optimized for gyros and is outstanding at slow air-speed 3D maneuvers like Rolling Harriers and Torque Rolls, to the stout DS160CLHV, which has the muscle to power your aircraft through many intermediate 3D maneuvers. And then there's the DS210CLHV, which will be your best choice when your skill set includes maneuvers like a Crankshafts.

Plus we offer you three in our all-alloy series like the DS205BLHV, the pricey alternative to our DS210CLHV which is pretty much the best +200oz-in class servo we know how to make what with brushless motor, which if you fly a lot makes the 5X longer lifespan means they're a no brainer. Are they worth the extra 10 bucks a pop over the DS210CLHV? It was to me, which is why I grabbed a set for *my* own Turbo Bushmaster build - but - it's not my decision, it's yours.

And of course, ProModeler offer two other mini-class all-alloy servos, which are both considered overkill, but which some amongst you may wish to investigate. These being the DS355CLHV (yes, 355oz-in of torque from a mini makes it a real monster) and the DS405BLHV. Both are considered complete and total overkill, but they exists for a reason, capisci? Like when your skillset either already includes, or you want to perfect, the high entry speed maneuvers that are really tough on servos like Wall, Parachute, and Rifle Roll

- DS210CLHV - full up aileron - eyeball the H-beam cross-section of PDRS32-25T servo arm

Servo arms

Last thing; you're going to need servo arms and compared to cheesium alternatives, let me mention the PDRS32-25T, a beauty with an H-beam profile for stiffness, and made of 7075-T6 aluminum for strength.

Especially nice about the PDRS32-25T (a 1-1/4" arm) is you also get a clamp mechanism. So the conventional M3 bolt is for fixing it axially to the output shaft, plus the M2.5 machine thread bolt that clamps it radially to the spline shaft.

These two actions totally preclude the arm form working its way loose *and* also prevents any possibility of play between how well the servo arm is broached and how well the splines were cut by the gear hobbers. Think of this as a twofer, or as belt and suspenders for the control system.

In the end, with ProModeler servos you get better parts - from the individual components that make up the servo, like the alloy finned center case for better cooling, better gears, better potentiometer, o-rings, bronze hardpoints, potting compound, cap screws instead of el cheapo Phillips heads - everything about them is top notch. Plus you can get better servo arms, too!

What's the best ProModeler servo for the Extreme Flight 84in wingspan Turbo Bushmaster? As usual, and no surprise to the pros amongst you, the answer is . . . it depends! We've tried to bring to your attention the factors to consider when selecting the best servos for your build! This, while being aware everyone has an opinion as we attempt to show you how to best account for price and performance to make the best decision for *your* needs!

Still have questions? Call us at 407-302-3361 and we'll try to help you!

Proof

OK, here's the last thing. Earlier I mentioned I'd prove our servos are built better than our competitors. Honestly, it's our opinion you don't even need to be an engineer to understand the differences for what makes one better than another - you just need a set of eyeballs Mk II.

What's more, *we* won't prove it to you, and instead, you'll prove it to yourself. How? Within the Head-2-Head section of the website we share side-by-side photos of competing servos. We did this for two reasons.

- many folks have never opened a servo to look at what they have, and

- competitors simply don't show you the insides (certainly not in the detail we do).

Yet isn't it what's inside that's the most important? Our purpose with this isn't to denigrate our competitors but to educate you. Why? It's because buying servos based on looks, specs, or what your buddy flies just isn't good enough. Not when you're being asked to spend your hard earned money! Our position is you should always get good value. Unless your money grows on tress meaning you don't care. Honestly? If this describes you, then we're not really making our products for you.

With regard to why our competitors only show the outside? We don't know, but with these tear downs you get to see inside what you bought and paid for and how it compares because if they won't show you, and magazine reviewers don't, then it falls on us to show you what we believe to be the competitive differences. After this, *you* decide what's best for you, nobody else.

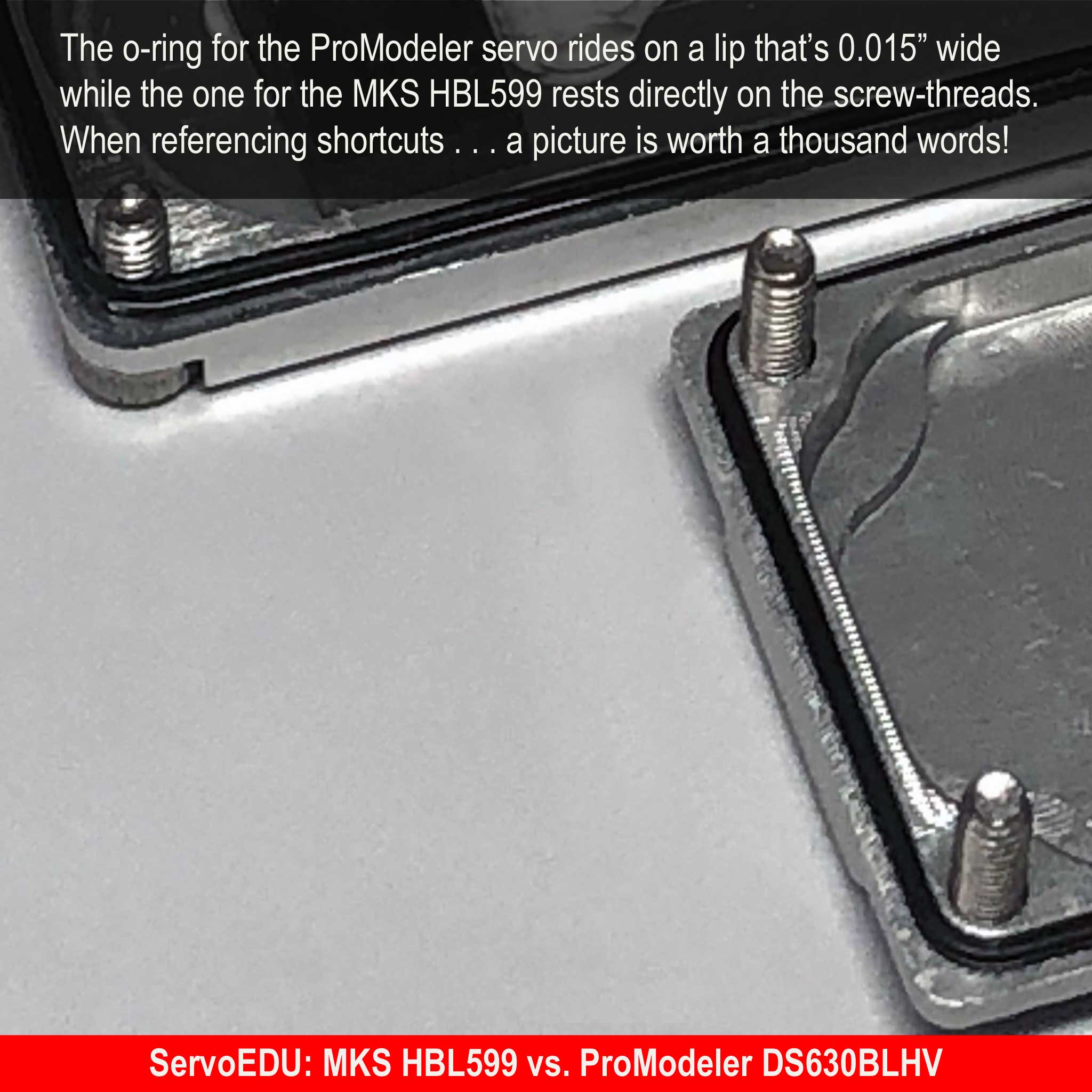

Why? Photos speak for themselves . . . like MKS HBL599 vs. DS630BLHV - or $200 vs. $120

. . . see what we mean? It's your money, spend it wisely!