What's this servo for?

Suitable uses for a DS1505BLHV include large unmanned vehicles for civilian consumer, defense contractors, ordinance disposal, and industry like;

- High performance RC trucks ranging from 10-20KG

- Fixed-wing tactical UAVs grossing 25-250Kg

- Squad-level remote sensing/surveillance

- Rotary-wing agricultural-spraying to 400Kg

- Ordinance disposal manipulators from 20-80Kg lift

Click Specs next.

Specifications

MIL SPEC

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

Making the ProModeler DS1735BLDP better is that unlike hobby-grade servos, it's built with MIL-SPEC components and tested to these MIL-STDS (military standards).

These are real world ownership considerations applicable to civilian-use, also.

Product Details

The principal DS1735BLDP use in RC trucks is steering. Big fast powerful rigs abuse steering servos like nothing else on Earth, but durability is the prime consideration.

Demanding applications like an SCX6, 1/5 EXB, or DBXL-E (and a host of others in the heavyweight-class) require the best performance considerations - like centering, power, and speed - but always rugged durability above all. This servo is engineered to deliver in spades! Let's see where the ruggedness is built in.

For example, the all-alloy case looks trick, but lots of imports servos have alloy cases. What separates ProModeler is how it's built.

Case has several jobs . . .

- Mounting tabs

- Cooling fins

- Transmission section

- Hard points for gear shafts

- Steel gears

- Environmental protection (seals)

Electronics Section

- Million-cycle potentiometer

- Potting compound on PCB

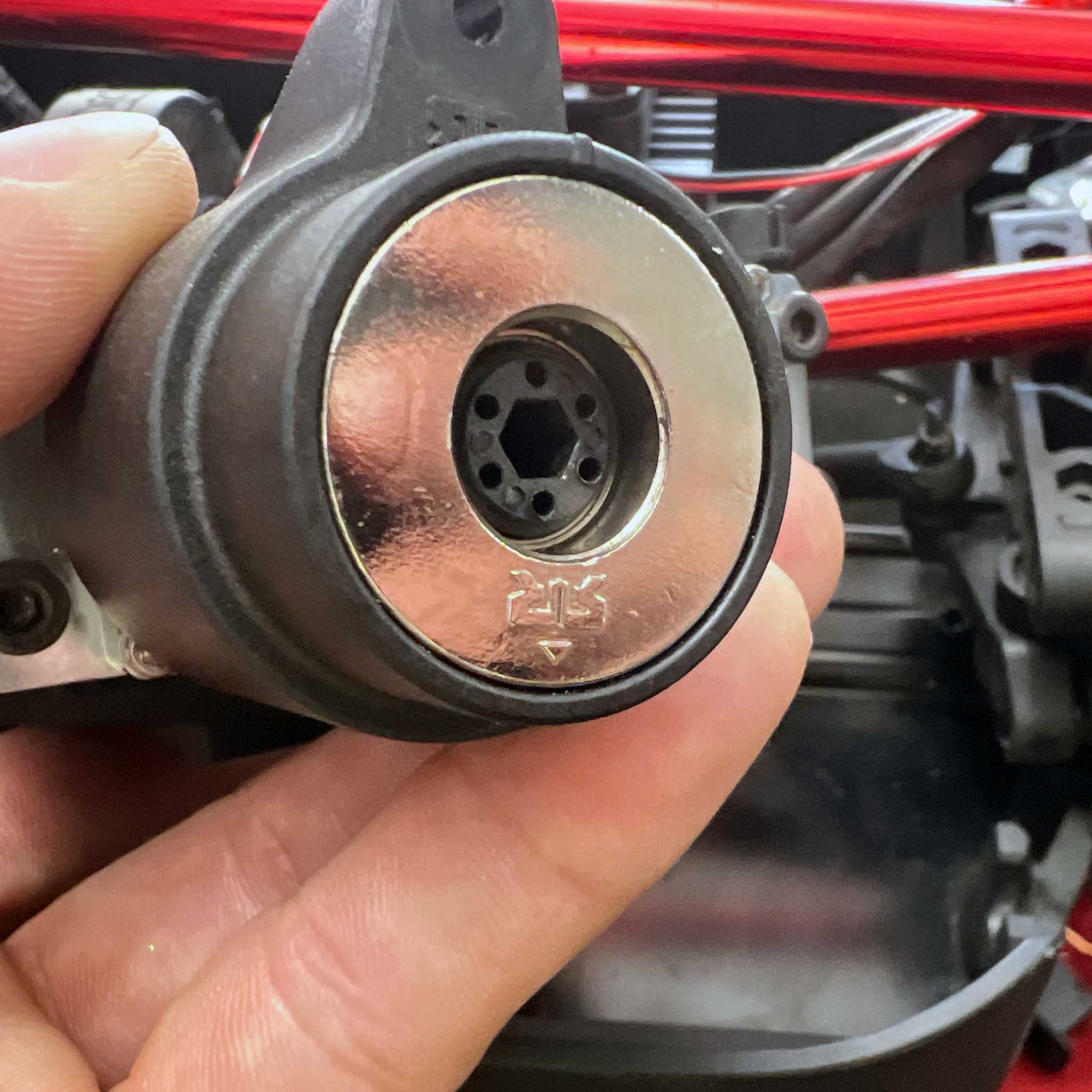

- Slip-fit brushless motor

To begin, the foundation is the 10-bolt construction. It's one where Allen head machine thread fasteners thread into the center case. This makes it more rigid in torsion (twisting force that's trying to lever the case sections apart and screw up the gear mesh). Reason this is important is if the gear-mesh changes under load it creates bad wear patterns leading to failure (basically bad juju for any servo).

Speaking of gears, they're all-steel. Why steel? Simple, because it's the best and most durable material available. For example, did you know NASCAR, drag racers, Ferraris, and Corvettes use all-steel gears, also? There's nothing better. Fact.

But equally important is where the steel gear shafts are anchored. In this servo, the gear shafts are anchored with bronze hard points embedded into aluminum. These reinforce the case and spread impact loads. Servos without these soon end up with round bores for the shafts that get pounded into an egg shape, thus allowing the gear mesh goes to Hell.

Believe me, if that happens then it's new gears 'and' a new case because you can't put new gears into a case with worn bores (you can but they'll get trashed really quickly). So what this really means is those servos are throw always. It's our view you're better off if we reinforce the case to begin with, agreed?

DP = Direct Power

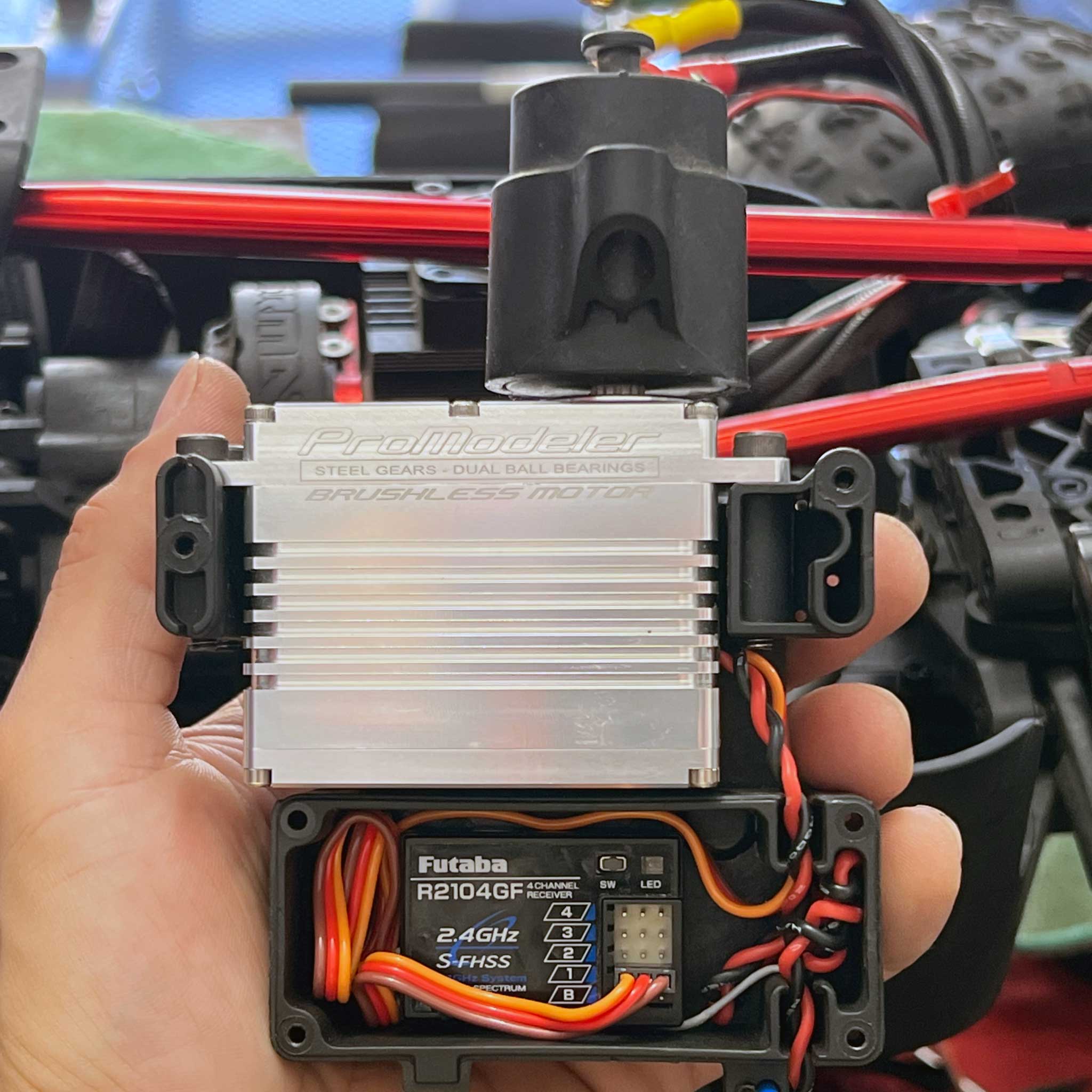

Direct Power . . . what's this mean? For anything you have in mind to use this servo you need to feed it a max of 8.4V. Doesn't mean you can't steal power from this 2S pack to feed the receiver too (consumes very little), but you must expressly feed it a clean source of 8.4V.

So there are two basic types of surface model this servo is commonly used in, gassers like a Losi 5ive and electric like an SCX6, DBXL-E, etc. For a gasser like a Losi 5five, this power source is going to be a 2S pack like this B2S2500. Why? Simple, because the servo can draw as much as 15A of current, which routed through the receiver would likely smoke the the lands (the little silver and gold colored traces connecting all the components of the circuits). This let's out the receiver's magic smoke. So smokin' the receiver is bad juju, capice? Costs you more money!

So to address this, we divorce the power for the receiver from the power for the servo itself. Yes, it still needs to plug in to the receiver for receiving the control signals (and to close the ground plane), but to operate it uses a totally separate source of power. This comes in via an XT-30 connector. This is how the servo actually runs the servo's motor.

To help out the owner of a gasser like a 5ive, we offer our packs with both an XT-30 for the servo 'and' a pair of Dupont connectors to power the receiver and whatever else you'd like to power, like LEDs. But not cooling fans. Never power fans from the same battery as is powering the servo and receiver, OK? And while we offer these packs with XT30 and dual Dupont in capacities ranging from 850mA to 6000mAh, we don't care from whom you buy the battery pack, just that you do. Why is this important?

Here's why, this the thing; while nitro/gassers have no choice but to use a battery to power this thing, a byproduct of electric powered rig like an SCX6, X-Maxx, DBXL-E, and others is they have a handy thing as part of the ESC called a BEC, a battery eliminator circuit. In compact rigs where a failure of imaginations leave the rookie befuddled for where to mount a separate 2S pack, the ESC can use a BEC-circuit to divert, or steal, some of the juice from the propulsion pack to operate control electronics. Don't do it!

Note; rookies love this because it's easier. They can be lazy and just charge the propulsion packs instead of also charging a control pack occasionally. Basically, not that they're dumb, but because they don't understand the downside of synthetic juice yet, they think it's OK. It ain't!

Basically, onboard electronics use FET (fast switches) to regulate some voltage down to another voltage, ike fomr an 8S 50V pack to a 3S 2-cell pack, or 4-cell - depends on the servo, remember, we offer both. Anyway, regardless, son't do this to power the servos.

Essentially, 100% of the times you interpose electronics between a battery and the control circuit you're decreasing the quality. Creating a synthetic power source is in no conceivable way even as good as any chemical source on the planet. Physics.

In short, there's no way a synthetic source is close to as good as natural chemical-generated power, it's like digital versus analog - seriously! The point I'm trying to make is no matter your budget, a BEC 'being digital can never' be as clean as the real thing. And if you know more about this than us, then we don't need to tell you, and if you know less than us, then read this to learn more.

propulsion battery We advising using a battery instead of a BEC because we don't want to warranty their product' delivering what they promise. Anyway, a battery is better than any synthetic source (meaning a BEC) for the same reason the best computer UPS (power back up) offer clean sine-wave versus digital delivery square-wave. Basically, the power of chemistry beats electronics and can't ever spike overvoltage like a BEC can. Just can't. And the current is higher without qualifying language regarding temeperatures and air flow cooling considerations weawel words the BEC manufacturers use.

Chemical beats digital every day. Downside is it's more trouble because in addition to the propulsion battery you're going to do the same as nitro racers do, maintain a separate control-power battery. Oh well, comes with the territory.

., we advise using a LiIon instead of LiPo because the metal shells protecting the cells are more robust than the Ziploc like polymer of a LiPo. Performance is macht nichts. Mounted between the shock struts delivers a compact package with the easy maintenance afforded by a clean looking installation. These three servos fit your SCX6 and which is best is up to you.

Installation - Axial SCX6

Axial's SCX6, an immensely popular large scale rig, is very rough on servos making the DS1735BLDP well suited for the rugged duty owners put the model through.

SCX6 we offer three great alternatives, the DS1735BLDP (2S), DS1885 (4S), and a DS2180, once again (2S). The (4) means up to 4S power, or 3.7x4, 14.8V nominal, we call it 15V but in practice it means a pack at 16.8V coming fresh off charge. Similarly, 2S means 7.4V nominal but in practice this is 8.4V in the real world.

DS1735BLDP

DS1885BLDP

DS2180BLDP

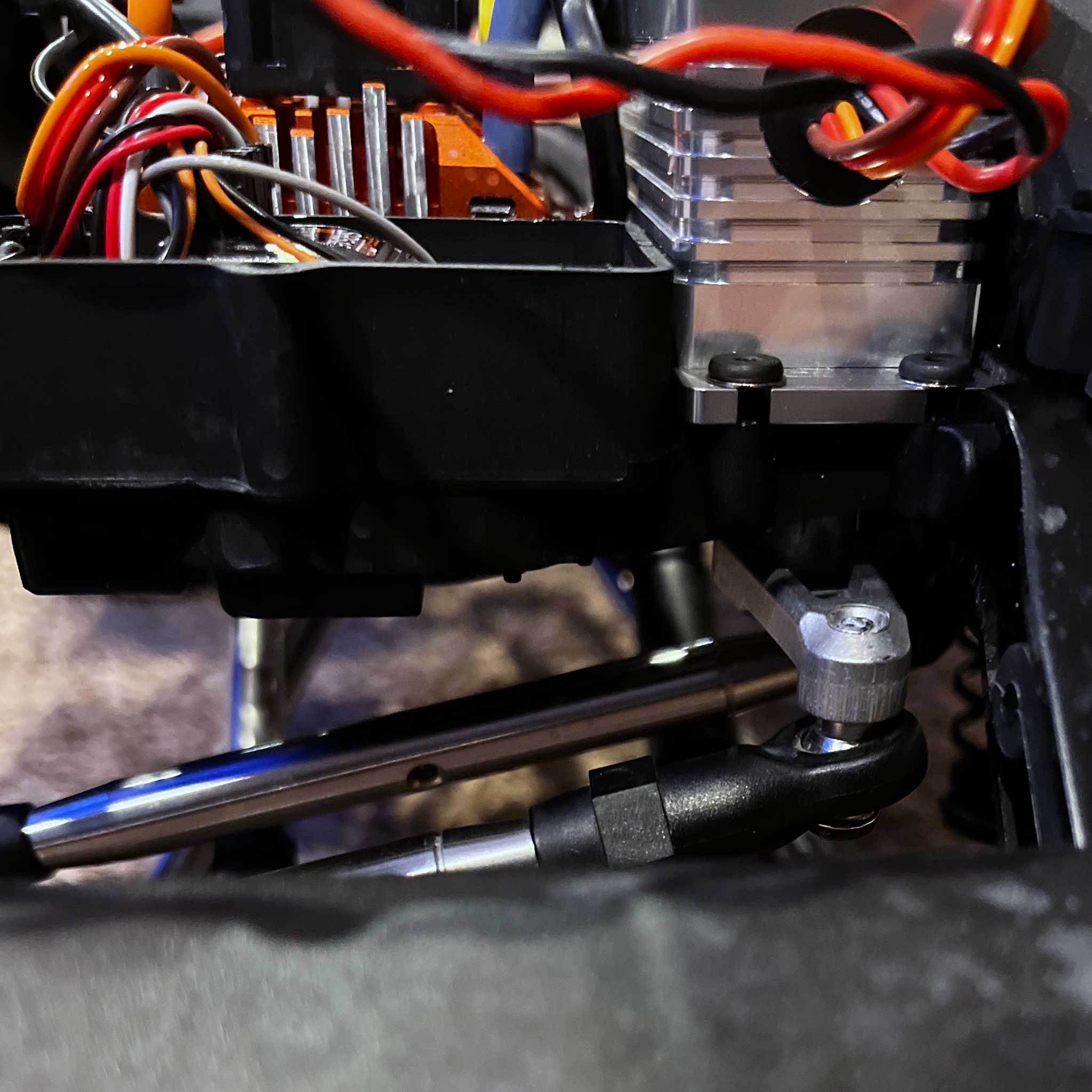

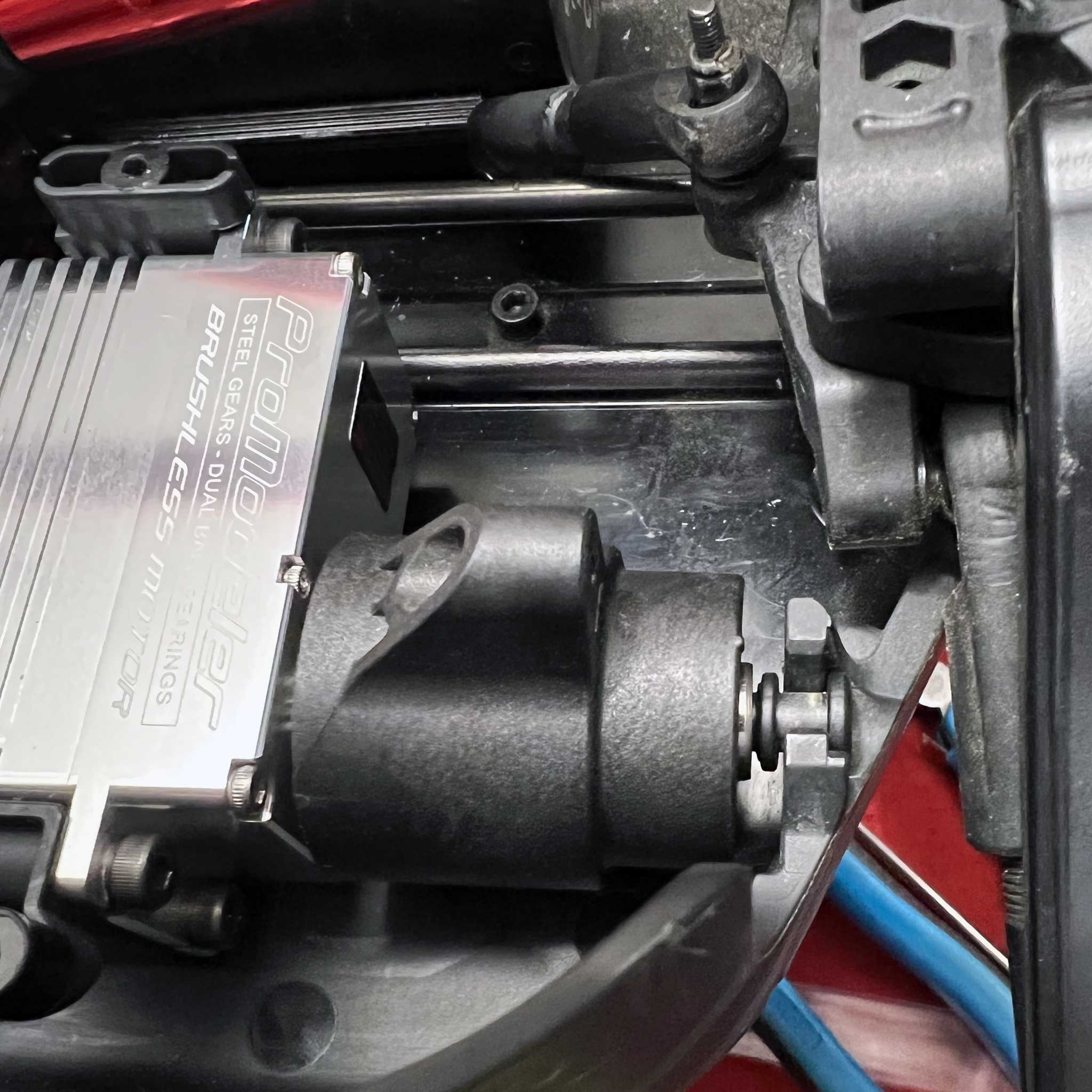

- Final installation of the direct power DS1735 servo within the Axial SCX6 truck

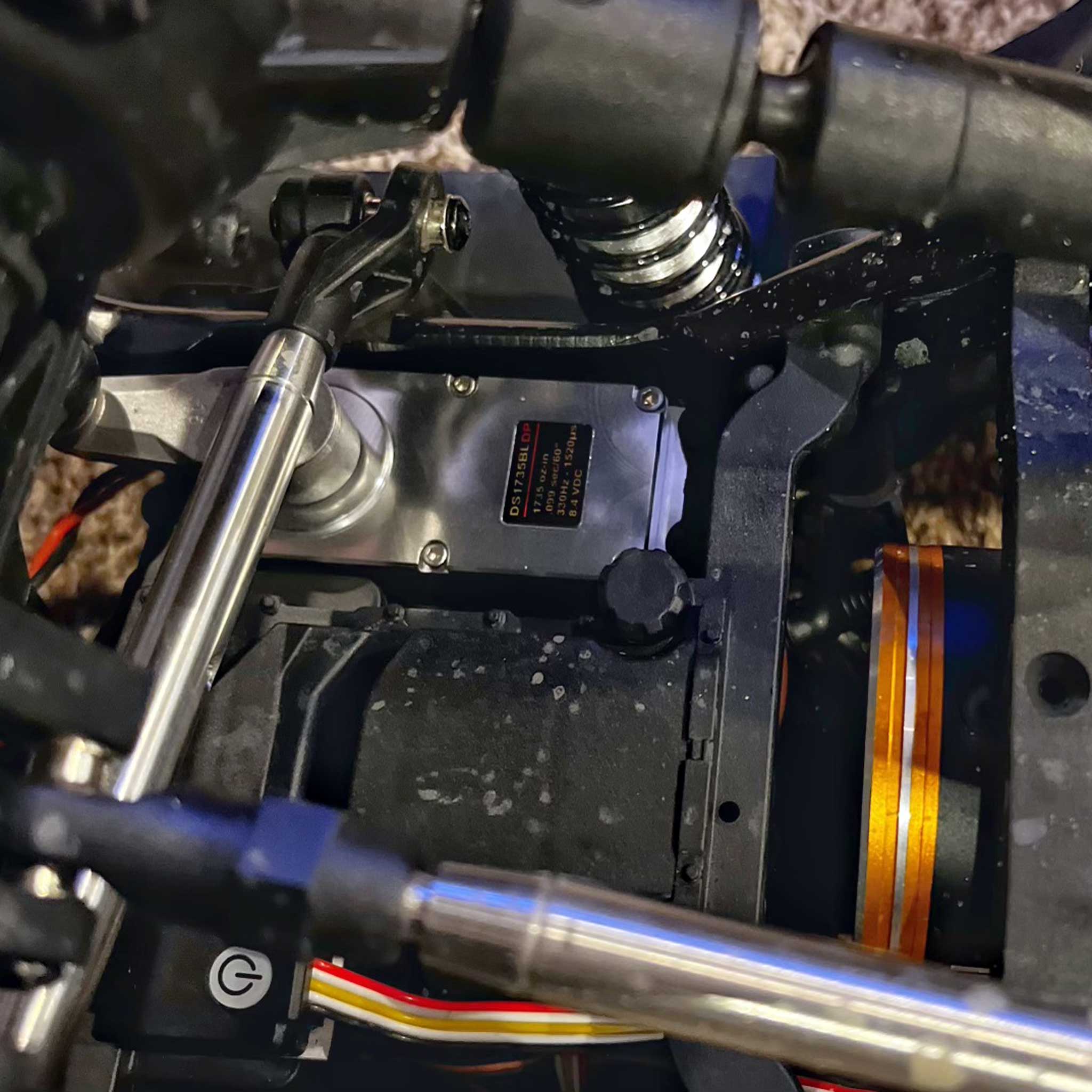

- Closeup look at the stock servo arm, which is retained helping save a few bucks!

- A different perspective of the DS1735 installation - this time from beneath

- Engine cover installed you can really appreciate the clean DS1735BLDP install

Installation - Losi 5iveT

This area will contain installation tips for this servo.

Installation - Losi DBXL-E 2.0

TEMPORARILY shows DS1885BLWR being installed but the DS1735BLDP fits similarly

Installation into this Losi DBXL 2.0 is a doodle. Basically you're going to shim it 5mm higher and replace the stock arm with one of ours along with a pack of adjustable links to compensate for the slight difference in output shaft position. That's it, easy peasy!

So the first step is to survey what you have, often a Spektrum SPMS906 steering servo.

- The stocker is a Spektrum servo, not bad per se but no pork belly, that's for sure!

Step two is removing the stock servo, which is so easy we won't tell you how. Please excuse the dirt!

- Look at the size of the installation bay - it's ginormous.

So next you're going to fix the beam mounts to the servo. A small drop of threadlocker is all that's called for, word to the wise.

- One the beam mounts are installed we're almost there.

All that's left is to shim the servo. Some 5mm thick shims will do the trick (hardware store item)

- Looking pretty good sitting there, eh? The Losi DBXL-E 2.0 is very generous in terms of space with which to work.

So we're almost done. All you need is a set of dual-linkages to replaced the fixed length plastic pushrods with ones you can adjust.

- While there are tons of available linkage kits, Losi's LOI351014 work just fine

So the last step is to install the linkage rods onto a servo arm and a PDRS40D-15T will do nicely.

- Subtrim the servo center, and set the end points and you're done!

Installation - Arrma Outcast 8S & Kraton 8S

Arrma’s 1/5th rigs - Outcast 8S and Kraton 8S - are incredibly popular because of their performance and versatility. With a longer wheelbase the Kraton's forte includes rally and Moto-X style racing, while the Outcast’s shorter wheelbase puts physics to work and makes it the triple backflip McTwist machine of stunt junkies!

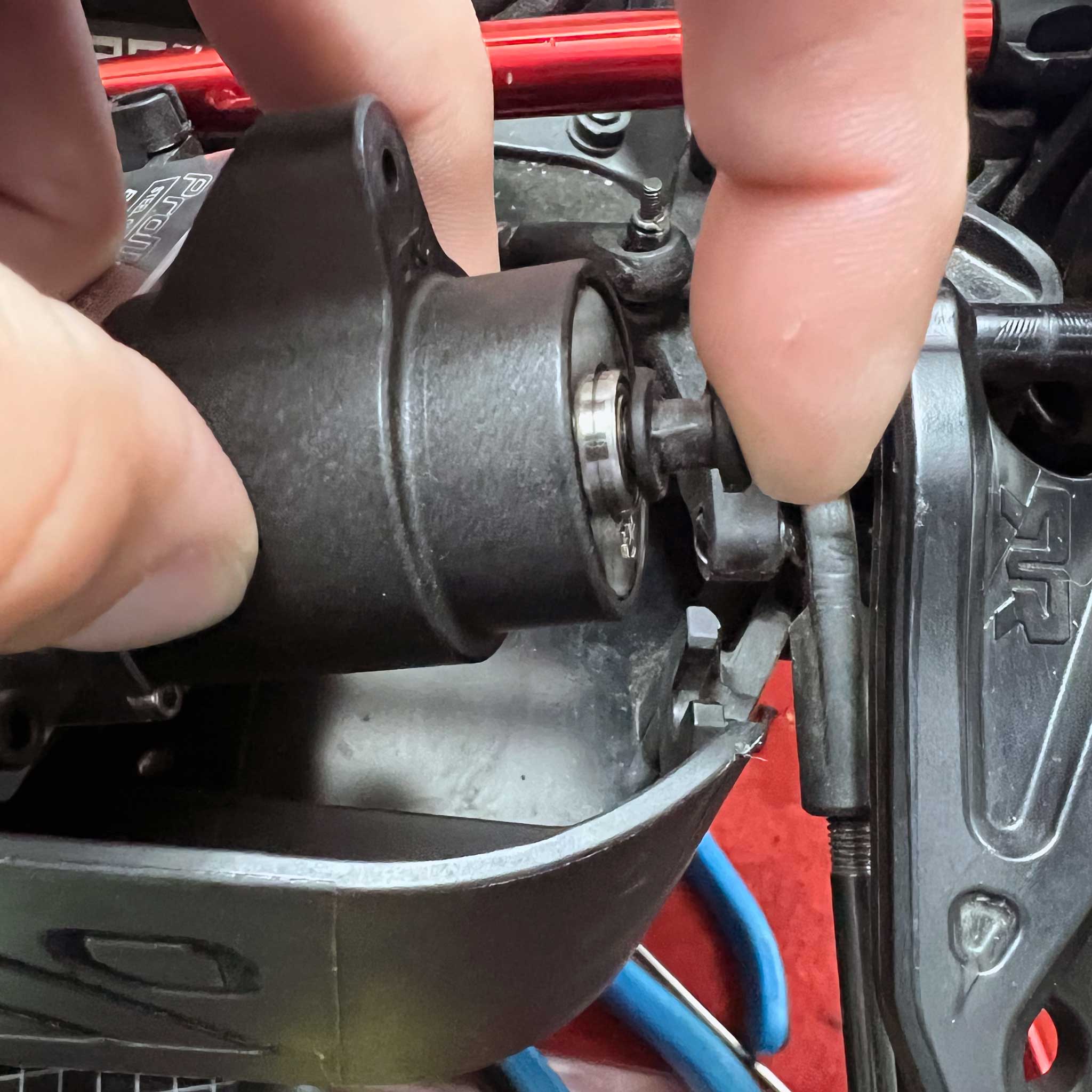

Both use the 1/5th receiver box for the DS1735BLDP . . . it simply bolts-in, no huhu whatsoever! Next, adjust the servo saver’s locking plug (ARA340165) by using the left-hand thread Allen bolt/washer (ARA340167) to set the correct depth for the bearing in which servo saver’s axle fits. You'll need a 4mm Allen driver.

These photo instructions focus solely on this adjustment as it's the only tricky bit.

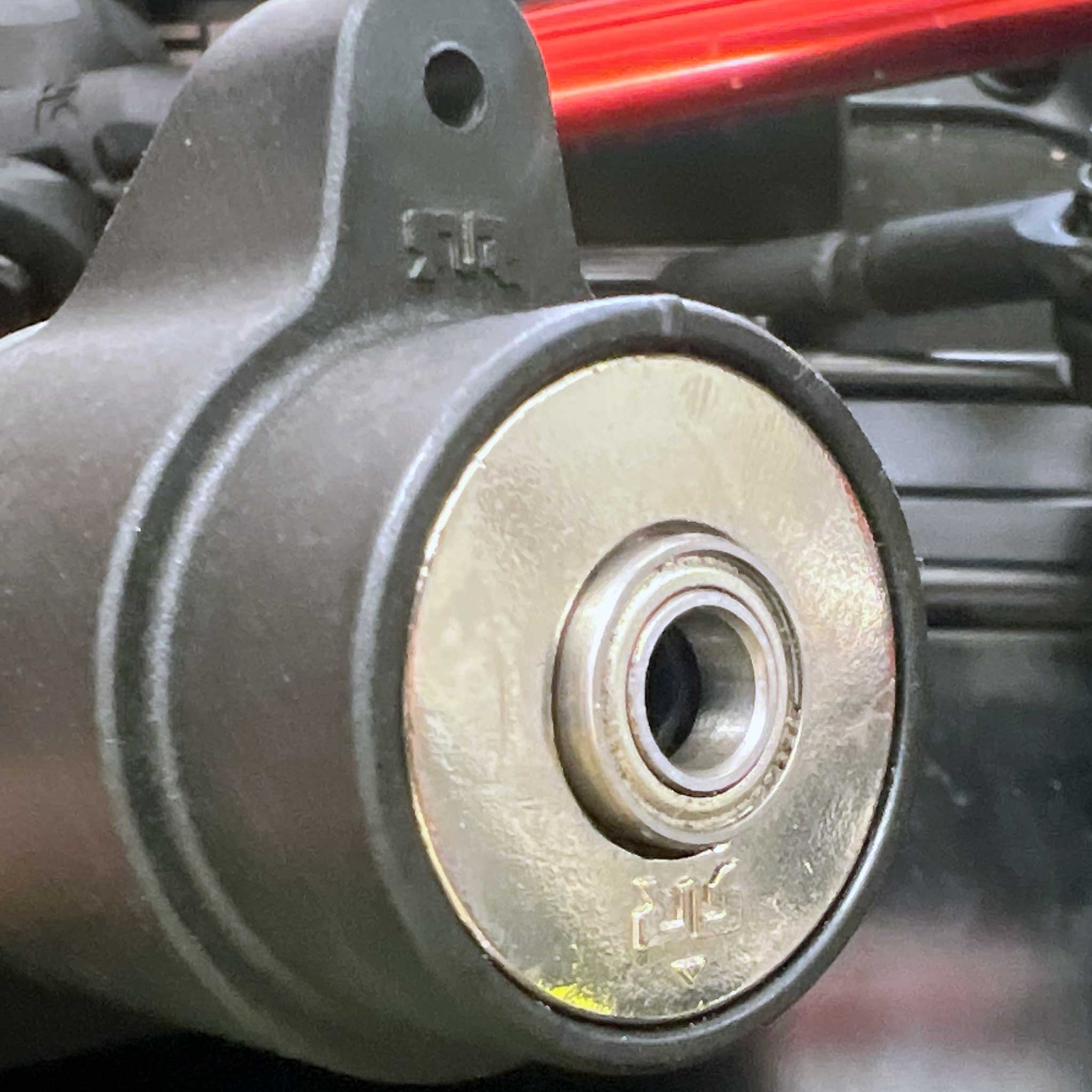

- The DS1735BLDP bolts right into the 1/5th receiver box - easy peasy!

- This is the servo saver’s locking plug, which you'll be adjusting

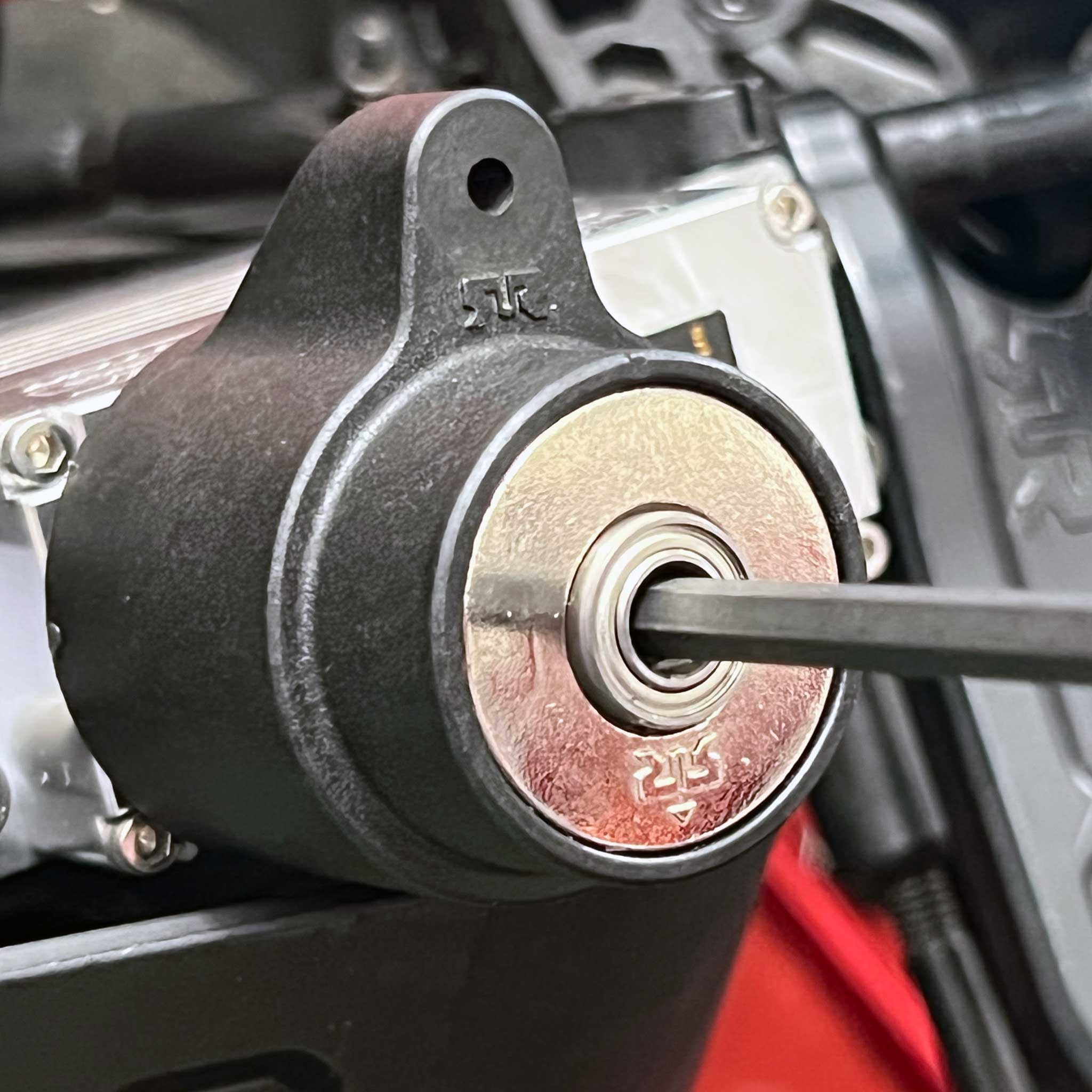

- You'll need a 4mm Allen driver, Bondhus makes a good one

- Once the bearing is in place you'll be feeling for it!

- Here the locking plug in position before placing the bearing in the bore

- Now you see it, now you don't - this adjustment sets the bearing depth.

- Perfect clearance for the 4mm Allen wrench to fit through the bearing

- Press the servo saver axle home and it's ready to test fit

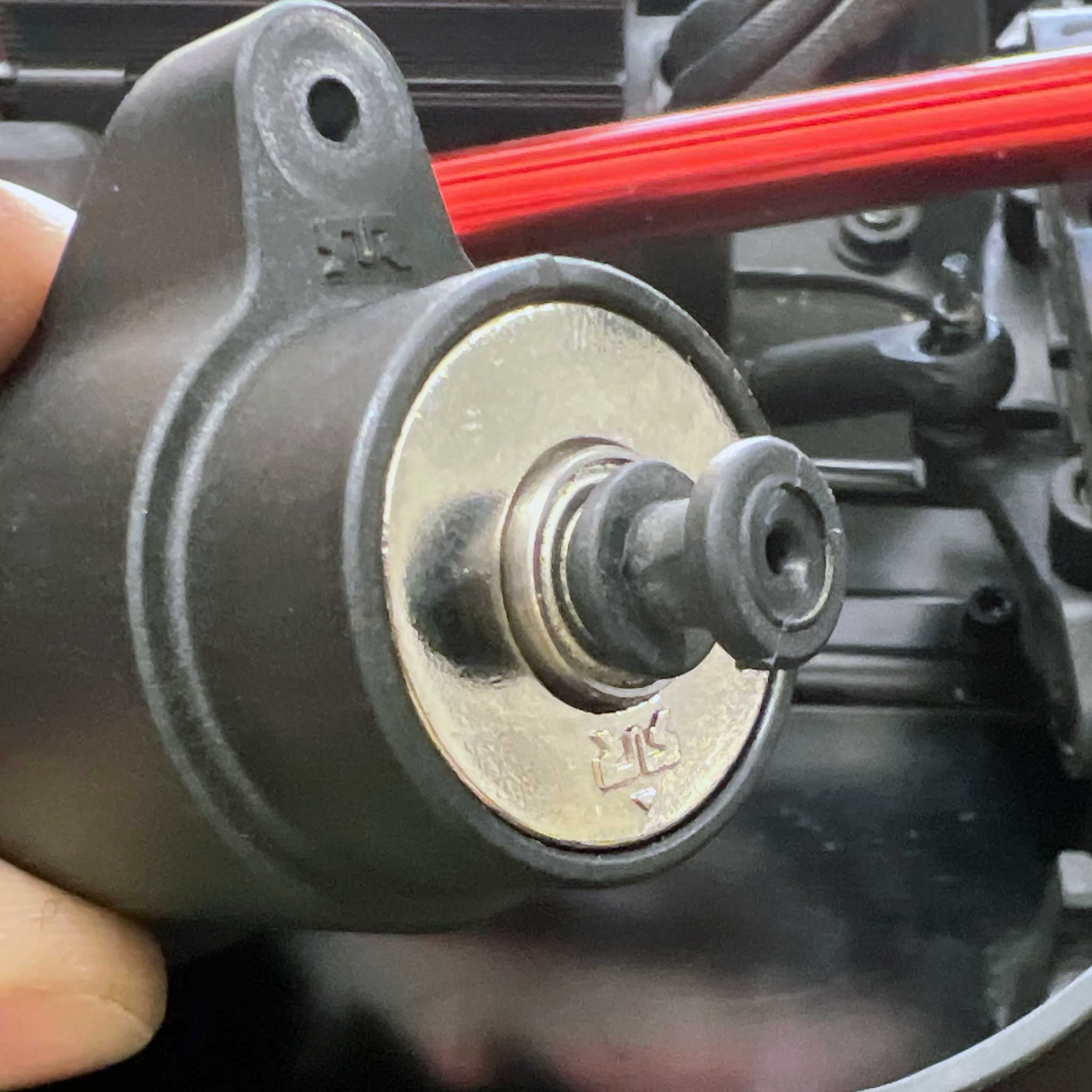

- Just remember, this is a LEFT-HAND thread to adjust the position of the axle

- When the axle fits the cradle like this, you're done, time to button things up!

Note; by replacing some of the stock plastic bits with aluminum, if you fancy a trick aftermarket servo saver from Vitavon or Hot Racing, they work the exact same way.

What you get

You'll receive a DS1735 servo. If you're smart, you'll have also ordered a B2S2000 battery pack to power the servo (it's a direct power servo, after all). This, versus trying to monkey around with a voltage regulator to parasitizing power from the propulsion pack . . . but that's on you.