The DS150CLHV is basically the same as the DS100DLHV except in the motor selection, which leads it to have about 50% more torque and be about 2X as fast. Consequently, it carries a modest price premium for the added performance.

In all honesty, 99% of modelers are served perfectly well by the less costly DS100DLHV - but without question - there are some amongst you for whom the added performance of the DS150CLHV makes the difference when you're performing 3DXA maneuvers and especially when you're flying SPA-class model like a Tiger Tail, Phoenix 5, or Kwik Fli. We created this servo for you as well as folks flying high performance like an Extra, Edge, Slick, and YAK.

Note:

These are tiny servos with even tinier gears and operating them manually via the servo horn may damage them. This damage is not covered by warranty. Please do not treat these like a standard size servos. You've been warned. Also, operating voltage is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo instead of a BEC. This is because LiPos deliver the required current without voltage spikes, noise, or otherwise adversely affecting the delicate avionics (15C or better is recommended). After all, synthetic orange colored Tang may have gone to the moon, but it doesn't compare to freshly squeezed orange juice. Same thing when it comes to feeding your avionics!

COMPETING SERVOS

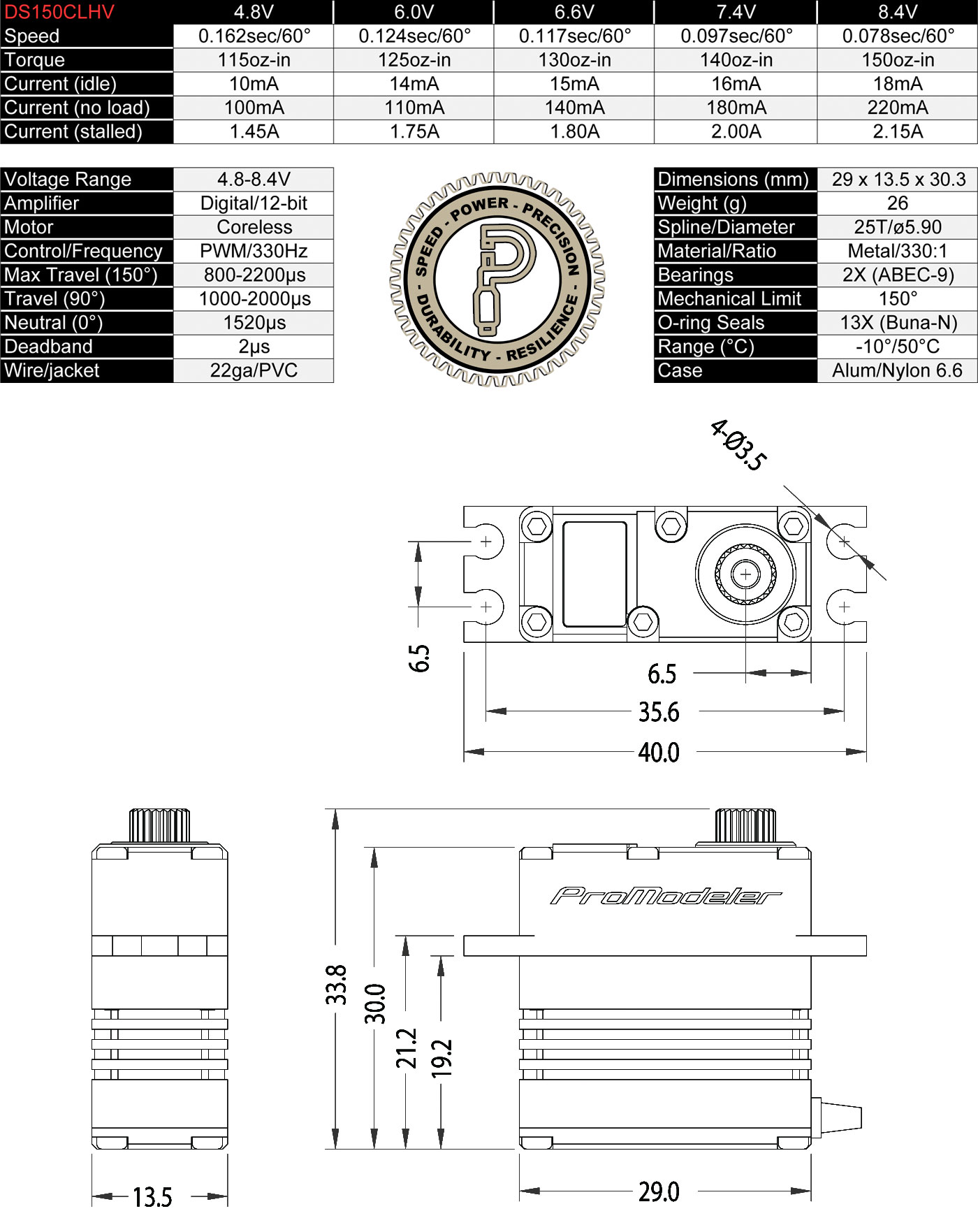

There are lots of micro servos available, but when you break out the tape, serious contenders are lacking. As a reminder, these are our basic specs:

- ProModeler DS150CLHV . . . @8.4V, 150 oz-in, 0.078sec/60°, $54.99

Someone on a forum wondered how the well regarded MKS HV69 compared and honestly, it's a pretty good micro-servo. Their basic specs are:

- MKS HV69 . . . @8.4V, 140 oz-in, 0.10sec/60°, $54.99

So it's priced the same, produces about the same torque, 'but' is about 20% slower. How's it otherwise compare? Here they are side-by-side - you decide.

Q&A various sources:

Q. James Speelman via Facebook; I'm curious how do you know what gears are stronger?

A. We know SAE65 is stronger in one of several ways. For example, because we also use aluminum (specifically 7075) for some of the gears within our lineup, we have real-world experience backing us up. Anyway, all (and I mean 100% of aluminum gears within servos, all brands, not just ours) receive a wear coating (hard anodizing) to help them last because gears are actually sliding surfaces and comparatively soft aluminum would be toast very quickly. But there is a difference between hard and tough and we refer to this as strength. So put another way, a hard wear coating is one thing in terms of durability but this doesn't make them any tougher. And this is a critical aspect of performance within our models because of how they're stressed - sometimes so hard there are pilots that may in some instances break the gear teeth themselves in flight (or with mere mortals, in a crash). So because aluminum gears aren't as durable you're going to be replacing them more quickly pretty much no matter what. Now this is usually OK depending on the amount of torque the servo will develop, but not always true. Anyway, SAE65 is a MUCH tougher material for gears. Source? Pretty much any engineering course in material science or specifically, gear design. And finally, empirically, we can easily prove this by testing to destruction where the ultimate strength of SAE65 matches the theory and the aluminum gears shear away their teeth wall before the SAE65 even begins to deform.

If you are considering a different micro-servo, tell us which one because we'll be very happy to tear one down and show it side-by-side with ours!

Overall Customer Rating of 6 Reviews: