Applications beyond military, commercial, and industrial for the DS2685BLDP include:

General Information

This massive 15T midi-class servo features a brushless motor and steel gears for enhanced durability. It's a wide input range DC-product designed to be powered from 8.4-15V (usually meaning a dedicated 4S LiIon battery pack, but feel free to try a BEC if you think it has the stones).

Built on a case CNC-machined from a solid billet of 6061-T6 aircraft aluminum, the gear shaft bores are reinforced with steel inserts to make the transmission section more rugged (competing products must be sent to a 3rd party for this).

Electronics comprise a double-side circuit board with the PCB being populated with MIL-SPEC components. These are protected against shock and vibration via potting compound. Note; the potentiometer is a genuine Japanese Noble (versus a cheapo knock off). And with regard to water intrusion, sealing is achieved via custom polyurethane moldings.

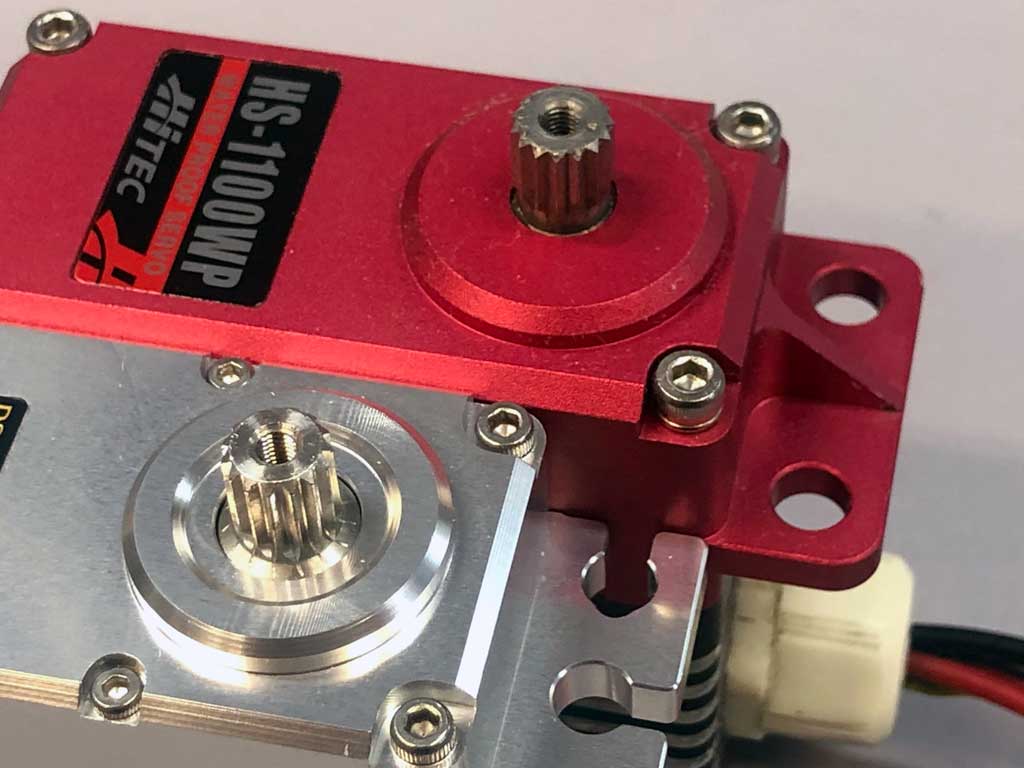

Pitted head-to-head with the well regarded Hitec HS-1100WP . . .

- Theirs uses a brushed-motor and ours uses brushless (lasts 5X longer).

- Theirs outputs considerably less torque and is significantly slower.

- Their case must be sent to a 3rd party to be reinforced, ours already is.

- Theirs is more costly because of the margin for distributors and dealers.

- Theirs doesn't meet MIL-STDS, plus ours uses MIL-SPEC components.

Direct Power:

The DP in the model number means this servo requires Direct Power. Anyway, this means it uses a Wide Range of juice (either 2S or 4S pack). While

we have them in capacities ranging from 650mAh to 6000mAh, the most popular pack is the B4S2500 and if you want one, then remember to add it to your order. Or select it from the pull-down menu under Power Options. Anyway, whether you buy a pack from us, or not, just so you know, the 4S 2500 is the most popular size, and it uses an XT30 - keep this in mind.

Also, if you have other ideas for powering it, like maybe using a stand-alone BEC like a Castle Creations CC BEC 2.0 or similar (we have these also), it's unlikely to have the stones to run the servo at full power.

Or if in the alternative, you're thinking of just tying into the propulsion pack, instead (maybe by tapping into two cells via the balance connector), then please be aware, a) those leads aren't large enough for the power demands, and b) ripple (electronic noise) due to the motor/ESC (as it varies throttle position) will backfeed into the circuit (on the servo) and damage a component on the PCB. We're expressly warning against doing this so you know in advance that repair cost won't be covered by warranty. Not trying to be an asshat, but also don't want this to become a problem, so heads up, eh?

Is having a servo meet MIL-STDS worth anything to you? Click and let's see!

MIL-STDS

Probably the most important thing differentiating ProModeler from ordinary imported hobby-grade servos is the use of military specification (MIL-SPEC) components 'and' that it's being built to meet military standards (MIL-STDS).

Turns out, what our primary customer requires of us (things like shock protection, anti-vibration measures, and protection against water intrusion) are pretty important to hobbyists as well. We're thinking win-win!

Not that we're comparing the shock to an airframe due to gunfire with your knocking a servo off a workbench. Nor loitering to keep eyes on the target during a thunderstorm with fording a small stream, but both present risks to the servo. And engine vibration in a model is probably worse just because the source of vibration is significantly closer to the servo, and every bit as destructive to electronics.

So while nothing in life is guaranteed but death and taxes, for sure if your servos are built to these test standards, then it's better than risking a pricey model on one built to hobby standards. But that's your lookout.

Bottom line? If you're picking between two identical servos, then the one meeting MIL-STDS is better - no question, right? After all, what's built and tested to military standards is just as beneficial for hobbyists but honestly, you're not picking between two identical servos.

It's not just because ProModeler is built to meet military standards, but because it's clearly built better. Maybe this sounds like marketing bullshit to your ears, but we're from the south where it's not bragging if you can prove it. So let's field strip them!

Then you can eyeball the insides of ours and our major competitor. Yup, look at them both side-by-side for yourself. After all, it's said a picture is worth a thousand words, right? But it's also said beauty is only skin deep (and ugly goes through and through). Maybe they won't show you the guts of theirs, but we're not afraid because it lets the product speak for itself!

Clicking on Photography closes this section, and opens that one, instead.

Photography

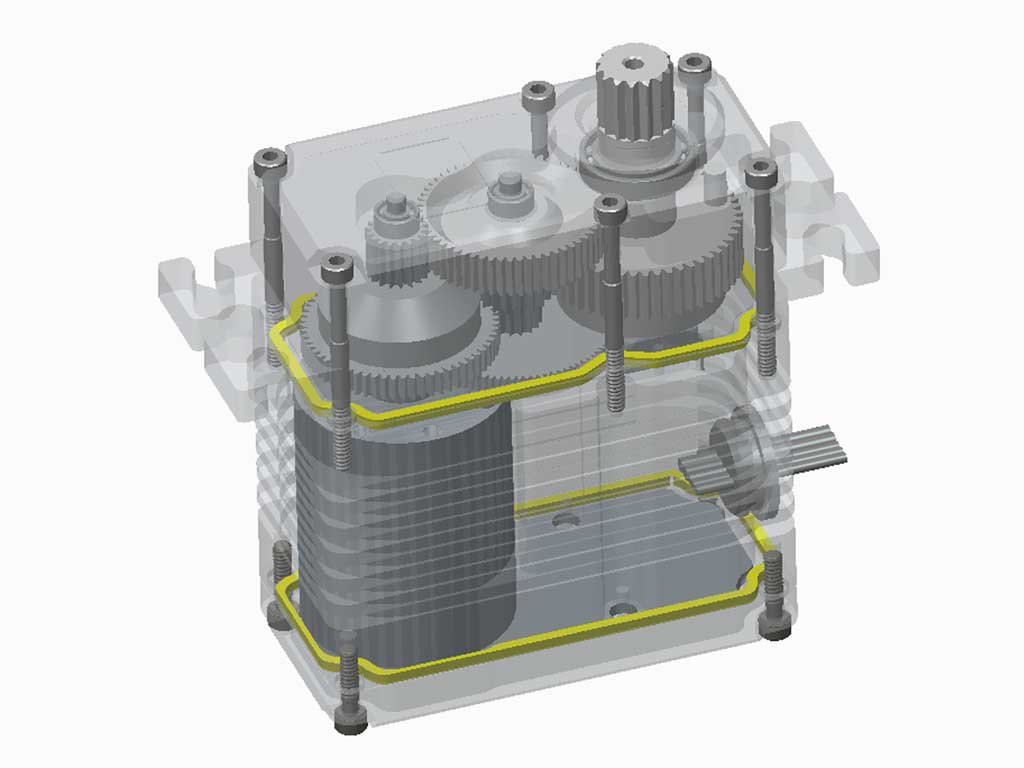

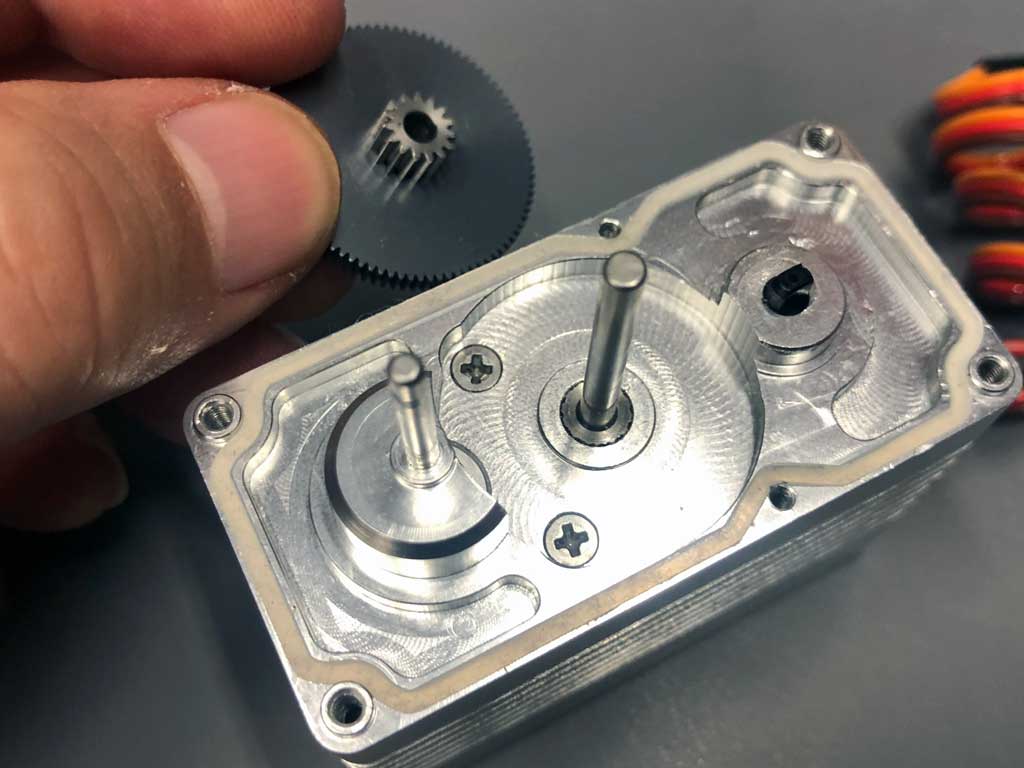

We'll begin with a render off the CAD-workstation (so you can see the design standard). Note; there are ten Allen-head machine-bolts, with six in the transmission section (and four boxing in the output shaft bearing for strength and rigidity).

By the way, servos often begin with a sketch (sometimes on a napkin over lunch as we discus competitor's product, we kid you not). But, when it's time for the actual designing process, we go to the computer.

The yellow? Those are the gaskets for sealing this beast against water intrusion. These are custom-molded polyurethane expressly for sealing this beast. And the gears? These are made of steel. It's the best material you can get (true whether it's for our servos or the transmission of a Mustang GT or even a money is no object Ferrari). There's nothing better!

- Note the 10 Allen head machine bolts securing the assembly together.

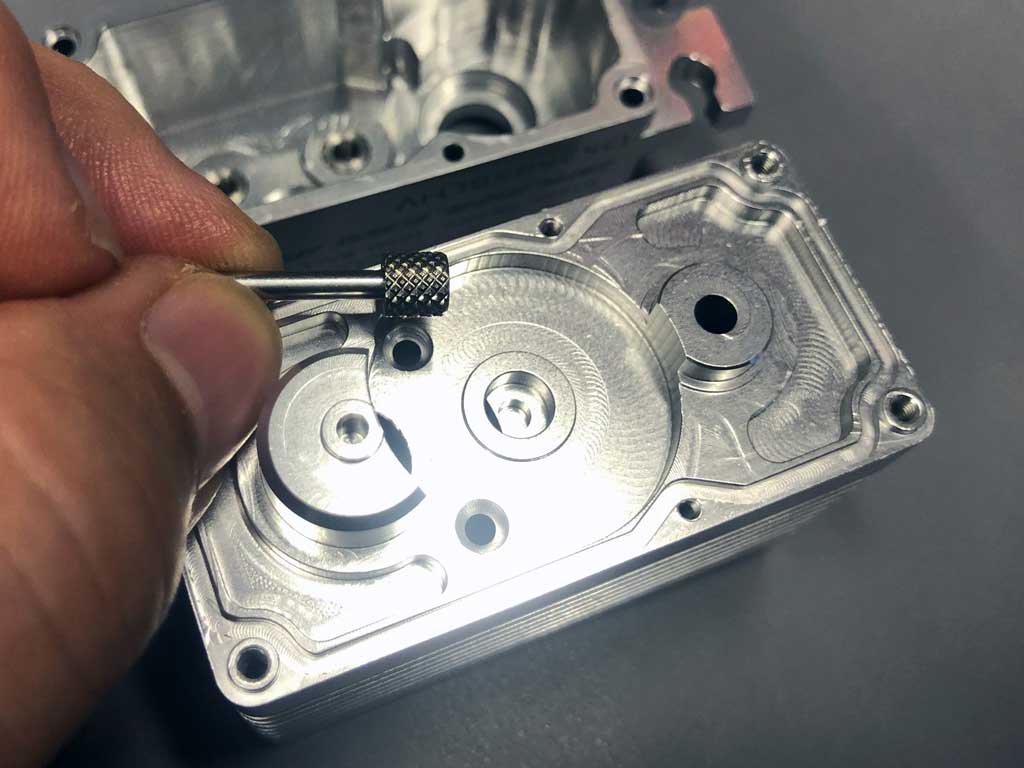

The center case is the foundation of the whole thing. It's what everything is mated to and it needs to be rigid to maintain gear mesh - and - it needs to help the motor shed heat when it's working hard. Both!

We begin with a solid billet of 6061-T6 aircraft aluminum and hog away everything that doesn't look like a servo (using a CNC-mill). To professionals, what's left looks like a work of art. Same with you?

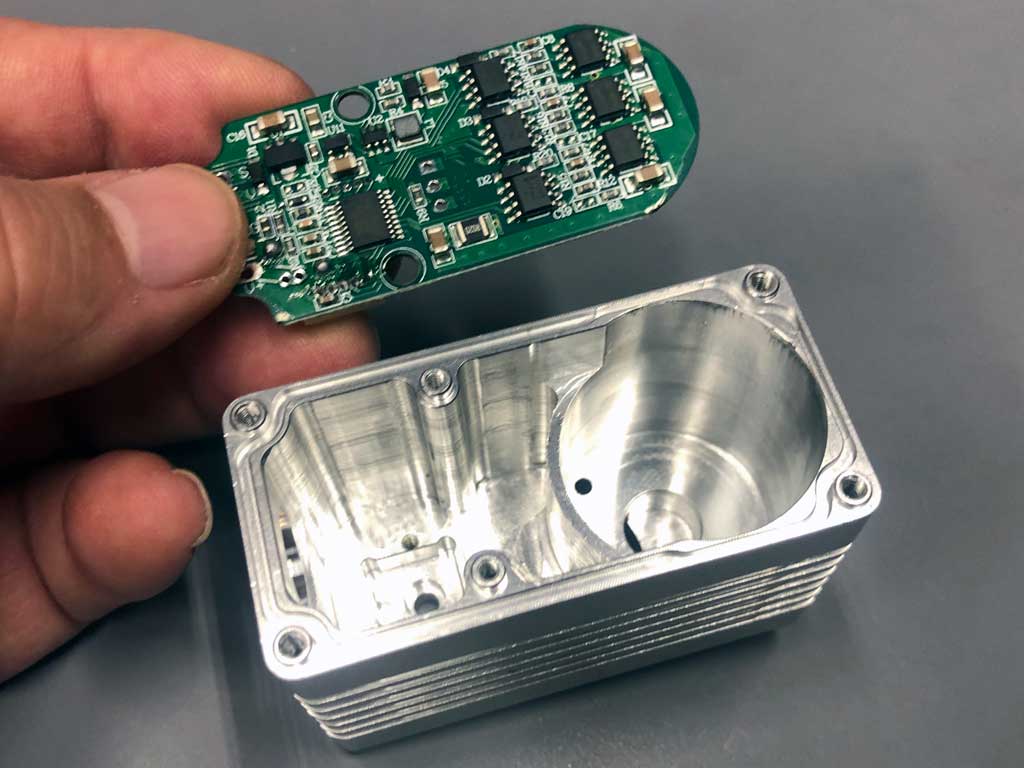

Anyway, if you appreciate finely made parts, then feast your peepers on these! What's that in my fingers? Read on because it's an important detail.

- Steel shafts into aluminum are a no-no - the best servos have hard points!

So here's the thing, if you want a servo like this to hold together then you have to go the extra mile. How? By providing hard points for the steel gear shafts (where they mate to the aluminum). Hard points work by spreading the load over a larger area. Otherwise, if you mate the shafts straight into the soft aluminum of the case, and then apply large loads, the bores wallow out (meaning they go egg-shaped from the constant pounding).

Ever wondered why the top guys not only pony up $500 for a competing product but immediately send it to a 3rd party to have them outfit it with hardpoints for another $100 (plus shipping). It's because hard point are how you ensure the gear mesh stays tight. What's the point of getting such a beast if the alignment goes to Hell when you hit stuff, anyway? So we do it from the get go because we know it's the only way to build the servo if you want the gear mesh to stay consistent over time.

Speaking of gear mesh going out, the funny thing is, first it happens slowly and then all at once. This is because once the gear shafts aren't in position for the proper gear mesh, it doesn't take a genius to realize what's next, right? Basically, that's when the gear train begins accelerated wear (and then it's pay $200, do not pass go). Not cheap, either because not only do you replace the gears but having learned your lesson, you ship it to someone else to reinforce it. Not ours because we're paying attention to this detail for you. Us? we don't get why they don't, but whatever because it provides an for us to earn their customer's business.

Sure, the saying you get what you pay for may be trite, but it's true. Installing hard points from the get go is maybe 'the' perfect example.

- Stout solid steel gear shafts as well as steel inserts - there's your beef!

Anyway, visit a competing servo's website. They're pretty on the outside (complete with flashy anodizing). Add a lot of advertising copy about how great they are. Maybe sponsored drivers (who get them for free touting them - like what else are they allowed to says?) but they're pretty! Inside? Could be another story. Be nice if they'd show you, right?

Want to know what sucks? Imagine you swallowed their sales pitch (hook, line, and sinker . . . meaning how someone who ponied up 500 bucks for the competing servo feels upon seeing how the inside of of their servo compares to this one). You know, that moment when they realize they paid through the nose and didn't get the best? Absolutely sucks!

And why? Could it be maybe they think you're too dumb to know the difference? Or that you'll never look? Or perhaps they don't appreciate how hard the top drivers run their rigs? Honestly, we dunno, we cannot fathom leaving out such a crucial reinforcements, but there you have it.

ProTip: if you're looking at our servo (maybe regretting how you've already bought a competing import), and only now realizing it's not up to scratch, don't sweat it. Why not? Simple, it's because there are American companies dedicated to retrofitting less well made imports with gear shaft hard points (so yeah, you can fix theirs but only if you throw more money at it). Funny thing is, some guys swear by those servos, even lend their reputation to them. And just because it's free to them? Go figure!

Anyway, not to belabor the point but this isn't rocket science. Since we know you're planning on installing this into a beast of an application, we're going to deliver what you expect to get. Especially for this kind of dough!

Why? It's because it's the right way to do the job.

- More bolts, more rigid. Webbing between bores? Ours is beefier there too.

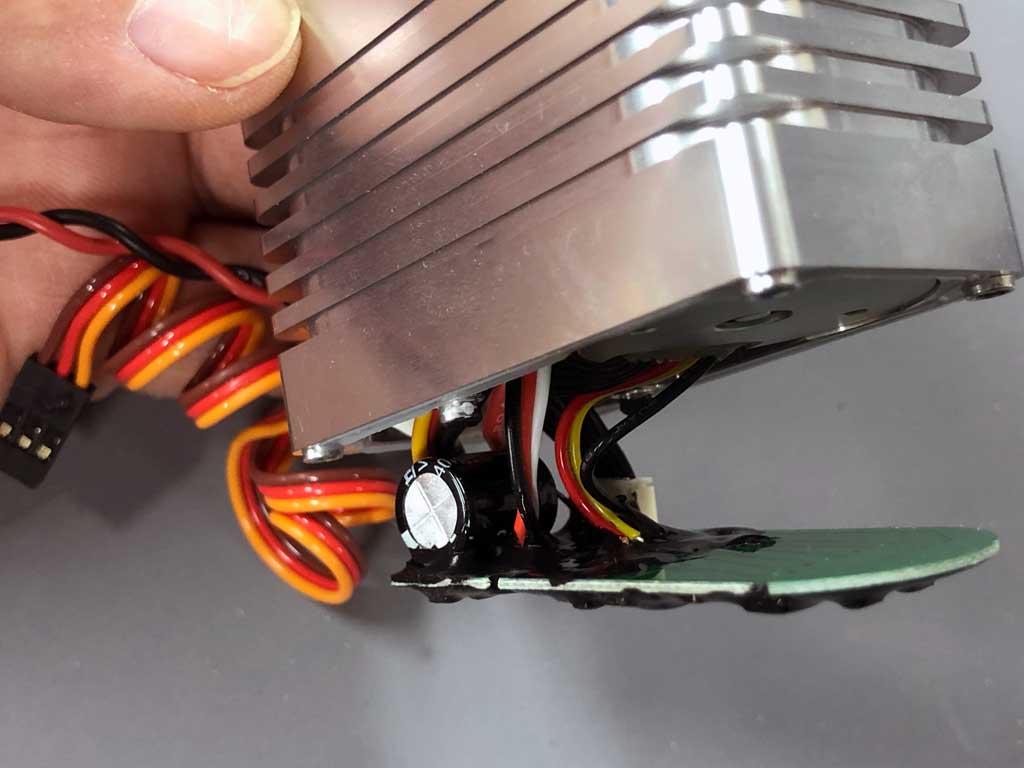

Next up is the servo motor itself. It's the heart of the whole deal. And basically, there are three kinds. We use the best money can buy. It's brushless, so it lasts 5X longer. And it's both powerful, and fast.

Don't know squat about motors? Then read up on them by clicking this link, which conveniently opens in a new tab so you don't lose your place;

The 3 types of motors found in RC servos.

Anyway, if you check the specs of competing designs, you'll soon discover another shortcut for saving on manufacturing costs - a lesser motor. Maybe it's because they don't know you. Or they have no clue how hard you're gonna run the rig, or fly the model. We start from the position you're gonna abuse the crap out of it and you want it to last a long time. Seriously, is there any other way to look at an investment in such a pricey servo?

Want to know something about cheap motors? They're not as strong, they wear out quickly, and they're slow as molasses in January! Anyway, top modelers buying this class of servo do it as an investment in the future. Not just how much fun they have a week or even a year form now but for how well it's still performing ten years from now. We're building this to the best possible standards and we you don't have to be an engineer to recognize it, you just need a set of eyes!

This servo is made for modelers who hold the highest possible standards.

- Readily identifiable by the connections, brushless motors are the best!

It's s a small touch, but take note of the output shaft. Sure, it's 15T and yes, it's beautifully broached from the very finest steel, but that purposeful look? It's because it has to be beastly strong. It gleams softly like a fine jewel because we take the time to stress relieve it and make it smooth. It's how we ensure you get what you pay for, the very finest quality.

Sure, we know it's just a small detail - but - in our book, it's the sum of all the little things that add up to make the whole package the best.

- Boxed in by 4 machine screws around the bearing, this is a stout beast

So what else is there to see? How about the PCB (printed circuit board)? We're proud of it because it's nicely designed to protect against shock damage (note two two mounting keys designed to slip over aluminum bosses machined into the case before being secured with two bolts). They, which along with the motor at one end and the leads at the other effectively give the assembly 4-point stability.

Competing products use single-point mounting and that's not the way you do things when the goal is to meet MIL-STDS for shock, capice? That, and take note how we protect the crap out of the individual components using thick potting compound for withstanding vibration.

Anyway, while we show it to you naked, this is because after you get it, it's coated in monkey snot. Just kidding (monkeys bite), but that's what we call it. Why? Simple, it's because it's a sticky and stinky mess to apply. Not kidding!

And what makes it especially costly isn't the price of the stuff (it 'is' pricey) but because it's time consuming to put on. This is because you have to go slow and careful or you spend a ton of time cleaning things up. Anyway, once it sets up, the components are encapsulated fully. This is actually an aerospace technique. It's also been used on circuit boards that have gone to the moon, as well as in every fighter jet built.

Why? Because it's the best way to protect against shock and vibration. The downside? It never gets work on again (but honestly, if something on one of these craps out you're going to want a brand new one because otherwise, you're never going to trust it again). So this board is made to be replaced outright.

And think about it; in the real world, taking into account what a good tech's time is worth, it's just how it has to be. Also note, the motor isn't soldered on, it plugs in, which makes for a quick and easy job so (point being, in the event it needs doing, it's done in a matter of minutes and without heating the board to un-solder and again to re-solder). Better. Trust us.

Find it strange we'd mention something can go wrong when we're telling you how great it is? You shouldn't because only God is perfect. The rest of us? We're doing the best we can. Ever gone to work on something only to find you first have to remove something else? Don't you hate it? Our view is designing with an eye to making repairs easy is smart. Some may say it's old school engineering to make things easy to repair. We're good with that!

Anyway, before application of monkey snot, below is what the circuit board looks like naked. Also, take note how - in the interest of protecting against shock damage - instead of depending on solder joints at the motor to help hold the PCB in place, ours are made with two alignment keys (holes). These slip over the shoulders machined into the case. This, so once the electronics cover and bolts engage over it, it's perfectly aligned and thus, firmly secured in place. After all, small design details count, right?

- Gleaming like a fine jewel, note mounting bosses machined into the case.

So once the motor and PCB are assembled, you're not going to really see the board components because the board gets coated with potting compound.

Note; this stuff can be either black or white. Doesn't matter, same stuff and which we use depends on the supplier. Anyway, the point of using it is expressly because it oozes into all the nooks and crannies of the components. Then once it sets up and it's fully encapsulated, it can withstand rocket launches, meaning serious G-forces! This is what you do when you're serious about protecting these things against shock and vibration.

And for what it's worth, we didn't invent this technique because this is a proven aerospace process! Moreover, it really is a total pain in the ass to apply. And as you may imagine, some on the assembly crew grumble the whole time they're doing it - but without it - it's not a ProModeler servo.

Oh, and if you're wondering, yes, it's applied to both sides. No shortcuts!

- No easy way; more time means more pay so more cost, but better servos!

The other guys? Honestly, some resort to a little piece of sticky backed foam, others don't use anything at all, and a few use 'economical' amounts of conformal coating compound (what my grandmother would have described as them being 'parsimonious' with it).

Parsimonious? Not familiar with the word? I'll save you the trouble of looking it up . . . means stingy! You want someone being stingy when it comes to protecting your servo? There's a reason we are known for the best servos.

Granted, the stuff's a little expensive, and of course, the employees earn more the longer something takes to do, but come on, it's not all that expensive. At least not compared to the value of your model, right?

Why pay such close attention to the smallest of details? Reason is to be found in the words of the world's greatest architect, Mies van der Rohe, who said . . . 'God is in the details.'

- Single-point solder-mounting vs. 4-point suspended and 100% coated.

And if you're curious regarding why our PCB is larger, it's because it's controlling a brushless motor instead of an ordinary brushed DC motor.

So the last thing to look at are gears. They're made of steel, both the pinons and the ring gears. Even the very thin 1st gear is made of steel. And we use the good stuff, too.

Did you take note the size of that big ass shaft? And the steel insert? Bottom line? This servo is a beast through and through!

- Totally sealed against the elements with a custom polyurethane gasket!

Next we'll show you the entire gear train. This is what you've been waiting for so without further ado, here it is assembled in all its glory. Note, we've posed it side-by-side with a good quality competing servo because we've got nothing to hide. Both are brand new never been run. This is what you get.

- Gorgeous gear train burnished to a sweet finish . . . you gotta love it!

In fact, we're even a bit proud of the gear train. But not too proud because some day a competitor will come along and try to knock us off. Since pride commeth before the fall, we're going to keep our heads up, and with clear eyes always look around at what's coming our way. You can help, too because if you think know of something better than the DS2685BLHV, then please tell us so we can buy one.

Honestly, we want to see any servo you think is better for ourselves because we're not sitting on our fat fannies at ProModeler. We'll happily take on all comers and if someone is doing us one better, then we'll apply what we learn from them and improve ours. We make you this promise, it's because we're not too proud to learn from others. It's what all good engineers do.

So there you go, we've had nothing to hide, and we've shown you everything that goes into making this puppy. What's more, we're not afraid to put it side-by-side with a significantly more costly competitor.

Reason being, when it comes to deciding where to spend your hard earned money, your alternatives include only one servo built to MIL-STDS. You can either believe marketing that chooses it's words carefully, or your own eyes.

Next, click either the Arrma Kraton 1/5 EXB or Warranty section.

Arrma Kraton 1/5 EXB

Warranty

Our warranty is pretty straightforward; 1-year parts and labor against defects in materials and workmanship. What's not covered?

Easy, customer abuse isn't. For example, if you tear up the gears, that's probably not covered because we're not saying our servos are unbreakable. Why not? Simple, it's because we're not stupid and 'anything' can be broken!

However, fair's fair and we'll certainly eyeball any damage because we want to do the right thing by you. OK, fair enough. So what's this really mean? Basically, that we'll look for a defect in the material, like maybe an occlusion (an occlusion is a void in the metal). Believe it or not, a metal isn't always solid through-and-through and it can have a tiny (or large) void.

Since voids are invisible defects in the metal, which may lead to failure, we look for them (because when metal tears away or breaks it exposes the void). So if we see 'anything' that lets us, then we'll absolutely warranty the gears. This, because we'll subsequently put in a claim with our gear hobber who will replace them for us because we replaced them for you. This is how these things work in the real world.

Thing is, just don't play us for fools, OK? For example, a fellow sent in his servo for repair. Said it was jammed and he hadn't done anything for it to act this way. Said he wanted us to repair it under warranty. Fair enough, we said send it in for a look-see.

By the way, fellow was kind of angry with us, also. We knew this because he'd added in his note how he believed we make crap servos. This, because it hadn't held up for even a complete run before he destroyed it.

Thing is, we totally grok being disappointed but eyeball this photo. That's a the steel output shaft . . . and is twisted! Honestly, that doesn't just happen on its own, take our meaning?

- Steel output shaft twisted like this requires a huge external force!

So once he saw this photo, the fellow gave an embarrassed little laughed. Then he allowed as 'maybe' he had abused it a little bit. So with a photo and a phone call we defused the situation.

Enough so he subsequently shared a video of what he likes doing with his rig. Seems he's into jumping it. He goes to a shop where they built custom ramps expressly for customers to come and jump their rigs (pretty smart if your business is selling and repair rigs).

Thing is, remember what I said earlier about nothing is unbreakable? This bit shows when he broke the servo. Whether it was the landing (likely) or after plowing into the wall at the end, we're not 100% sure it without question, it wasn't nothing, agreed?

- Black rig lands hard, crashes against wall, results in twisted output shaft!

Anyway, this brief 5 second clip is near the very end of a much longer clip. During the early part he'd clearly shown the skills of an awesome driver because he nailed most jumps. I mean like everybody who sees the clip is amazed how good the guy is (yes, I have it saved on my phone).

That said, you don't get to be good at anything without a bunch of practice. And with jumping, this means crashing . . . a lot! You gotta pay to play, folks. It's the natural order of things. True, whether it's shooting a bow, solving a quadratic equation, or jumping heavy rigs. Takes practice.

So being good at anything takes practice, and being real good means 'lots' of practice. Doesn't mean we're going to pay when the thing lands wrong and twists the output shaft. Not how it works, OK? Note, his rig? It easily weighs as much as a bowling ball. Honestly, against those forces, nothing is going to hold up. Not to that!

He knew, too. Maybe thought we wouldn't notice. But not fair to us or anyone because if we warranty it, it also means we're going to have to pass the costs on to the next guy. And that's totally not fair. Be straight with us.

Another example is when a fellow says the servo won't turn. Tech opens it up and some gear teeth are sheared off. This gear is made of steel and this kind of damage doesn't happen on it's own. Either he crashed it hard, or dropped it off the top floor of a parking garage (whatever, but it's not a warranty repair).

We want your business - but right now - we're showing you up front where we draw the line. If you disagree, then take your business elsewhere.

- Steel gear with teeth sheared off from a hard impact - not warranty!

Point being, in the above photo immediately above we;

1. don't know what happened because we never got video of it crashing

2. nor were we there to see

. . . but please don't take us for stupid!

Remember, we're not out to make cheapo servos, we're trying to make the very best. Major point being, you absolutely will not tear up steel gears doing nuttin', OK?

For our part, building the best we can means selecting the best materials. Believe us when we say, you can't shear off the teeth of a gear under normal use or twist the output shaft without huge external forces. We know it. You know. Man up, tell us what happened when you broke it and we'll try our best to help.

We make them, we can repair them, but don't expect us to pay for stupid!

So what about warranty for the electronics? This is easy too. We're quite liberal in our warranty coverage - but - not for some things.

For example, we can tell if a servo got hit by too much voltage. Most are rated to 8.4V and some are rated to 15V. Regardless, we can take one look and immediately know if an 8.4V servo got hit by 11.1V because a fellow hooked it up to a 3S LiPo. It's because of 'what' goes poof. And no, we're not gonna warranty it, either. Yes, we can repair it by slipping in a new hot-section and it'll work like brand new but we're not going to eat the cost of you being dumb.

Similarly, when a servo's failed because you forgot to set the end points and burned it up, then that's on you once again, not us. We'll repair it but not for free, not as part of the warranty.

We've seen it all, believe us. We know how and when they fail and we're happy as can be to make the repair for free 'if' it's our fault, e.g. materials of workmanship. That's the deal we're agreeing to up front.

So just like a guy who buys a new pickup truck and goes muddin' with his pals, clogs the radiator leading to the engine overheating and then has a flatbed fetch it to the dealer, they're not going to warranty customer abuse and install a new engine . . . we're not either.

Guys love our servos for crawlers, airplanes, boats, robotics, etc. Thing is, sometimes a rig gets stuck and the driver wiggles the steering back and forth. You know, trying to get it loose. We do the same thing! Thing is, you gotta know when to quit because if you continue too long, poof go the output transistors. Guess what? Not warranty. You have to know when to stop and walk over to free it by hand! Don't come whinging to us claiming you didn't do nuttin', OK?

We're not going to warranty this stuff because it's not our fault. You can burn up any servo on this good Earth doing this. You did it, accept it, don't blame us. Or go buy an import and see if they'll buy that cock and bull story how you didn't do nothing and it just failed, because we're not.

Look, there's not a servo in the world proof against stupid, OK? Learn from it and move on. What shouldn't you do? Don't play us for idiots because we can repair your servo (and you'll learn what not to do when your rig gets stuck, next time). This, by the way is what we're talking about . . .

- Output transistor gave up the ghost on this one and no, it's not warranty!

Last point we want to make. Does Ford warranty the injectors of an engine when you run shitty gas with water through them? You bet your hind end they won't. Point being, we are not fans of BECs. Reason is they can fail low (0-volts), fail high (pack-voltage, maybe 30-50 volts), or be intermittent.

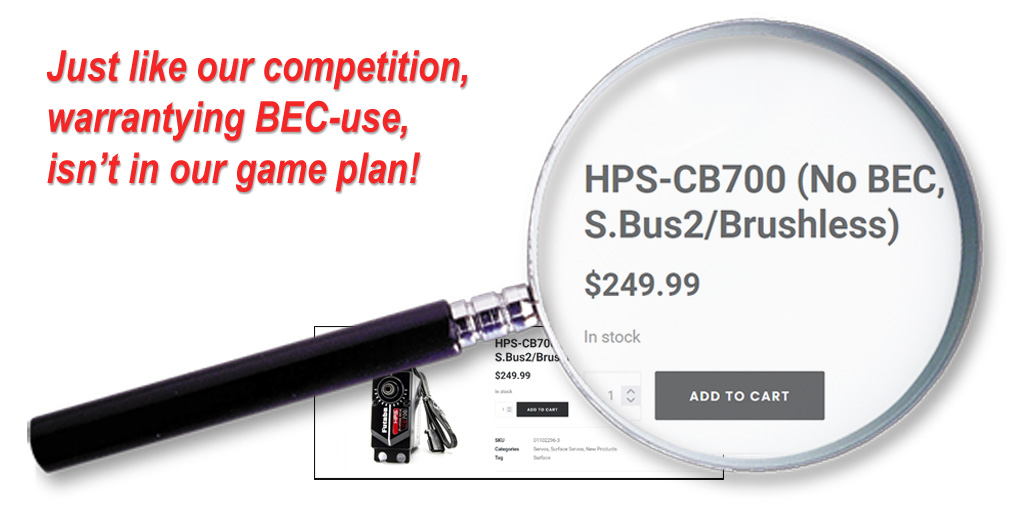

So when we see a failure due to someone being lazy and running a BEC instead of a dedicated pack, we're not going to want to warranty the damage. Competitors like Futaba don't, and we're not keen to do it either.

Seriously, folks like to feed servos with a BEC because it's easier, and we're telling you don't use these things. You insist because, whatever, maybe you're too lazy to run a dedicated pack. Don't know but don't get your panties in a wad when the servo gives up because we'll know what happened.

Look, bottom line? A product warranty is designed to protect you and us.

You only care about you, we get it. And note; we want to make you happy. But we're not going to pick up the tab for stupid. Be reasonable and you'll be glad you're doing business with us. Mistreat us and we'll recommend you buy an import servo, instead.

We love you, but nobody hangs around when they're being mistreated. Your girlfriend won't do it, your dog won't, and neither will we! Nor do we expect you to if the shoe is on the other foot. Point is, we promise not to mistreat you, and if you don't mistreat us . . . then it's all good!