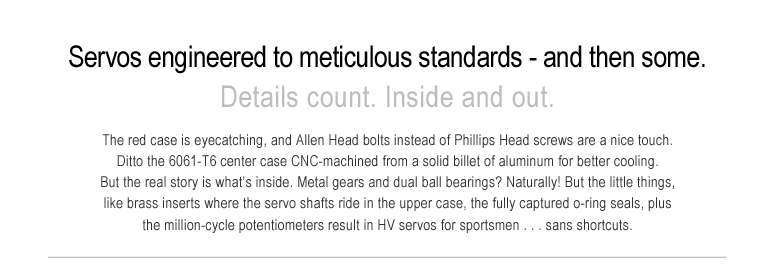

The DS270DLHV is a high voltage (HV) digital servo built on a hybrid aluminum/polymer case that outputs 270oz-in with a transit time of 0.12sec/60°. This servo will often find a home in sport models where it's perfect, and IMAC and 3D models spanning 74-78" and powered by 35cc engines. This, because it centers superbly and is, quite simply, built better than others in its class. But it's merely OK for folks seeking 3D on the cheap because it's really designed for sport-use.

While the torque is adequate, the speed is still rather slow for 3D - but more importantly - they're not built to the same level of precision as other servos in our line-up. This holds down costs, but is also why they're not really suitable for 3D-use. Put another way, these servos are great for a sport pilot flying a 74" Edge 540T, but they simply aren't the best servo choice for the model of 3D is on your mind because long servo arms and exaggerated throws will immediately expose the DS270's sporting-heritage (another way of saying its shortfalls).

Be like someone calling to bitch they bought a Fiat to play boy racer at Monza and it's unsatisfactory because it's not carving corners as precisely as a Ferrari costing 10X as much. Does that make the Fiat a bad commuter? Nope! And note for just 2X as much as our 'Fiat' , we offer you servos that *will* deliver the Ferrari experience!

A far better selection for the 74-78" Edge or Extra would be our DS415 or DS505 brushless servos. And servo arm wise, PDRS101 if you're happy with polymer, or PDRS25-25T if you'd rather have alloy, and if 3D is what's on your mind, then our PDRS35-25T are far superior to the cheapo el cheapo alloy arms offered by a country mile.

For example, mechanically, everything depends on the DS270's center-case. To begin, it's hogged out of a solid billet of 6061-T6 aircraft aluminum. Then, because cooling is critical for long motor life we CNC-mill the cooling fins. Also, because stiffness is critical for maintaining gear mesh, instead of securing the assembly with 4 screws, we use 10 Allen head machine bolts . . . and beneath each is an o-ring!

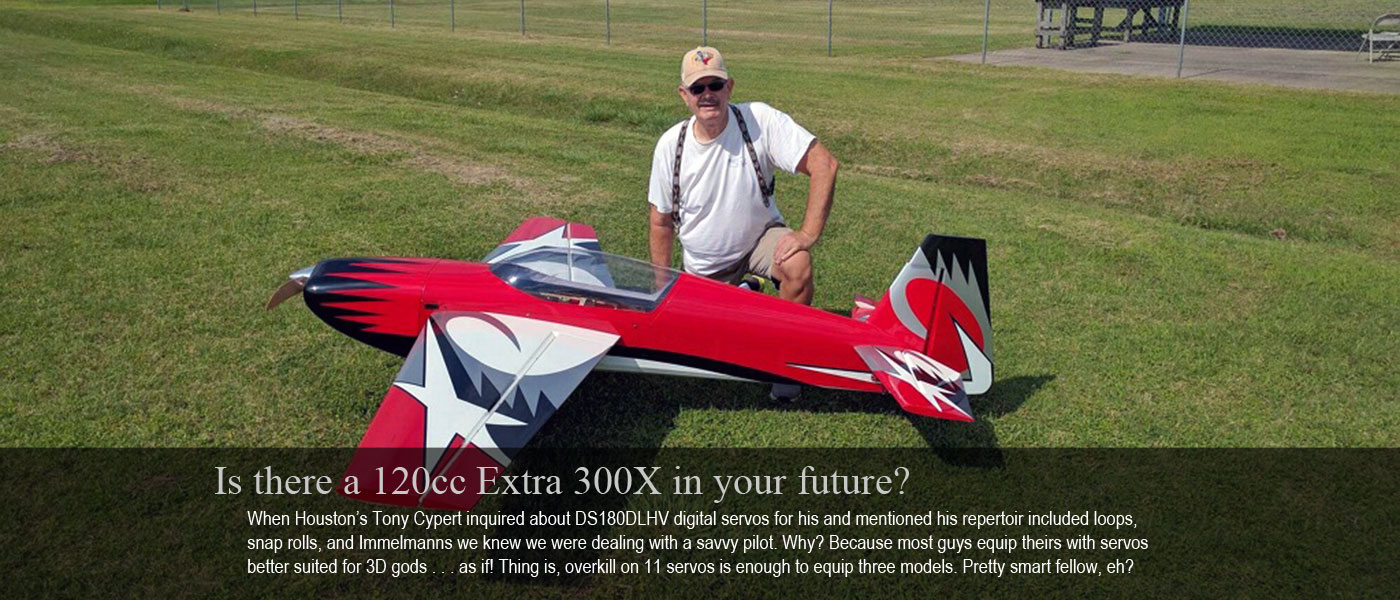

What about the things you can't see? All servos use steel shafts for the gears but while other fit them into plastic pockets, we reinforce our upper case pockets with bronze inserts because this gives you the durability of an all-metal case without the weight or the expense. The gears? All metal, of course and where the 25T spline exits the case, there's another o-ring! And instead of garden variety ABEC-3 bearings, you get the highest precision ABEC-9 because it results in reduced freeplay!

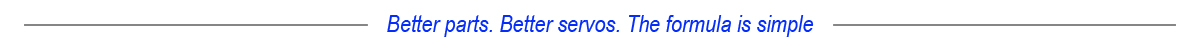

It gets better, because taking a page for the aerospace industry, the critical PCB (printed circuit board) receives a conformal coating to better protect the components against shock and vibration. Plus two more o-rings where the three case sections come together (for a total of 13 o-rings protecting your investment. You won't find another servo on the market that is this well protected - at any price!

Oh yeah, the electronic components are MIL-SPEC because the tighter tolerances result in better centering. And the potentiometer? It's is a genuine million-cycle Japanese Nobel-brand instead of a knockoff. Anyway, this is what's called a standard-size servo (meaning it fits most remote control models, even .40-size). And to help you figure out whether this is the servo for your next project, we've grouped information into various tabs. For example;

- Specs - useful if you're curious about the raw numbers, dimensions, etc.

- Comparison - a guide regarding how it compares to other products.

- TL;DR - gets down into the weeds with the nitty gritty - it's for the detail-oriented.

- Reviews - short and sweet with real names and places - no BS.

INTRODUCTION:

Part of what makes the ProModeler DS270DLHV the right servo for your model is unlike hobby-grade servos, it's built to meet military standards (and subjected to these tests).

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

While you may not need servos that can deal with the shock of 20mm rounds impacting the airframe, isn't it nice to know you're flying with ones that can? And because it's assembled with 13 o-rings, exposure to summer afternoon pop-up rain showers, exhaust oil, or putting a model on floats to attend a float fly doesn't mean you need to take special precautions.

Ownership Considerations:

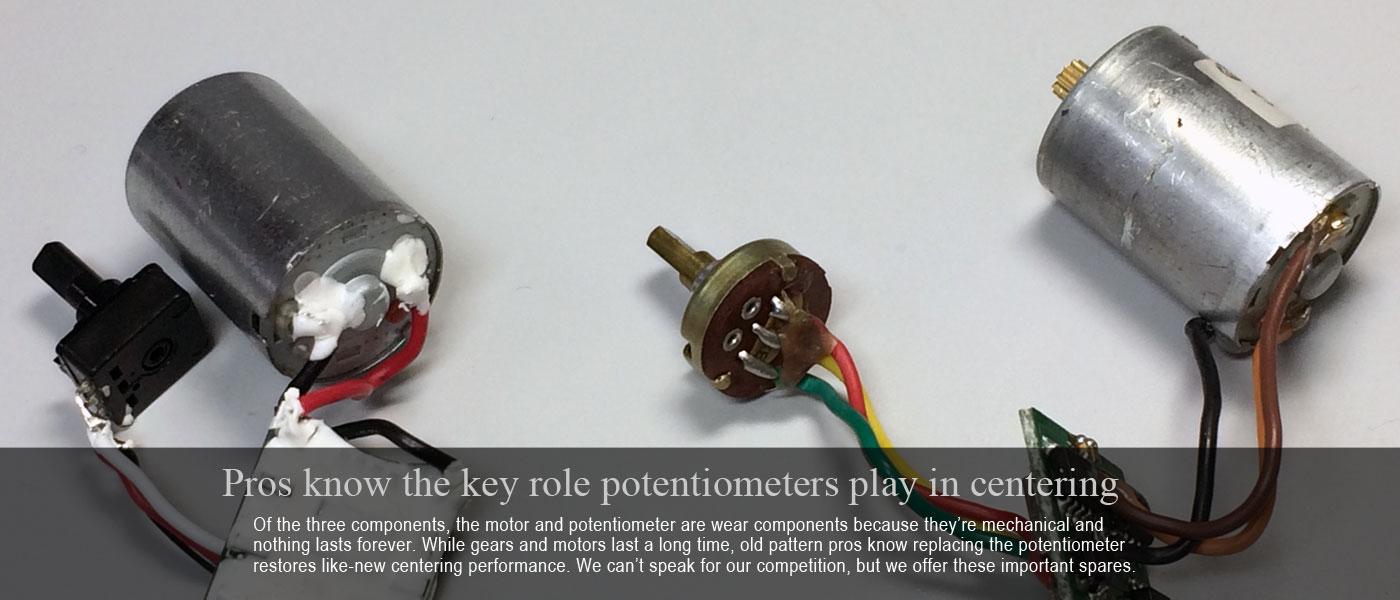

When it's time for repairs, everybody offers DIY modelers components like gears and cases. But if you're a competitor, you'll be pleased to know we also offer you motors and potentiometers. This is because 'full' spares support is a requirement of military contracts . . . and this is a game changer in the world of civilian-use servos.

For example, sport pilots probably won't ever fly enough to wear out our servos, but IMAC pilots - hard core competitors whom over the course of 40 weeks will put in 30 flights/week - are a different story! After all, 6 practice flights/day (which they do 3X/week) plus twice more on weekends, works out to 1200 flights/year! Thus, even our million-cycle pots need to be replaced yearly to restore like new centering when you fly that much. The other guys? They require you to return your servos for service meaning by the time you pay their service department for the parts and labor (and don't forget postage) you're more than half way to the price of new servos! Coincidence? Fortunately, replacing pots is an easy DIY job - 3 solder joints isn't rocket science!

DETAILS:

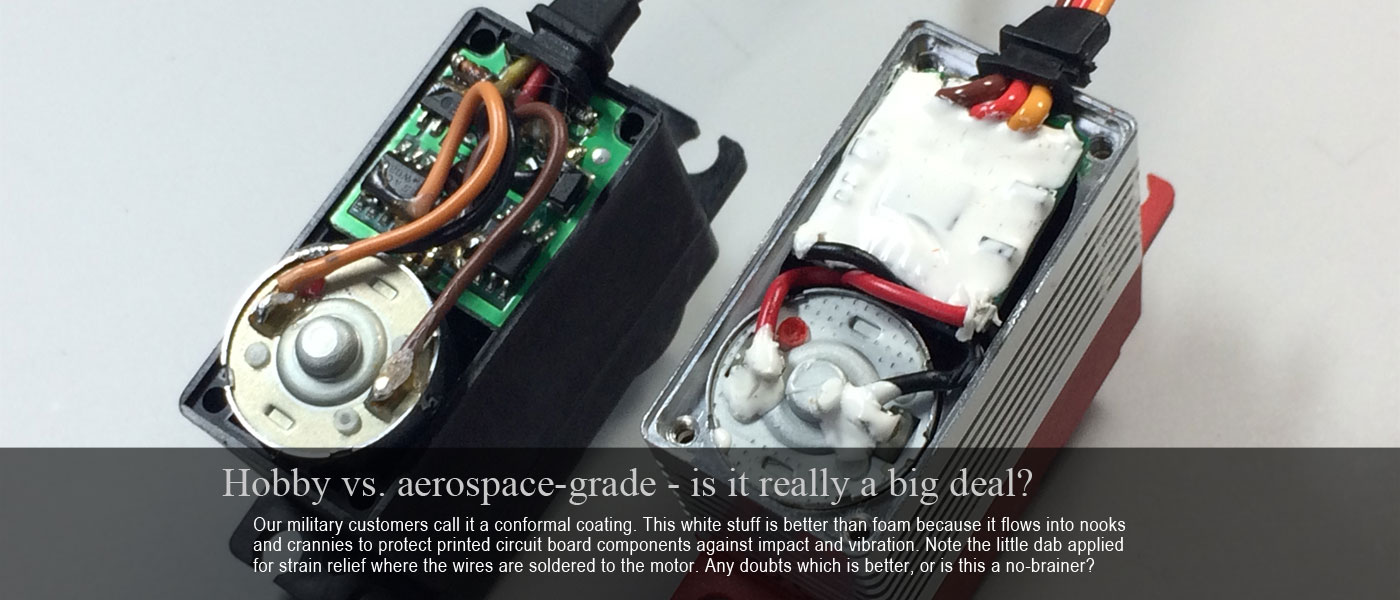

If you're an electrical engineer you'll immediately notice we protect the PCB from vibration with a conformal coating instead of a little square of foam rubber. Referred to as potting compound on the civilian side, we call it monkey-snot because it's such a sticky mess to apply. This stuff is applied to the PCB and oozes between components and once it sets is what lets our servos thrive in harsh high-vibration environments. This is an aerospace-grade technique and it makes ProModeler servos more valuable.

Another area where a ProModeler servos stand out is protection from environmental contaminants, typically dust, water, and exhaust-oil. The assembly of the DS180DLHV is protected with o-rings - basically at every opening - even beneath the screw heads! We all know how pernicious water can be with respect to penetrating where we don't want it so this detail helps make ProModeler servos better. It's a no brainer.

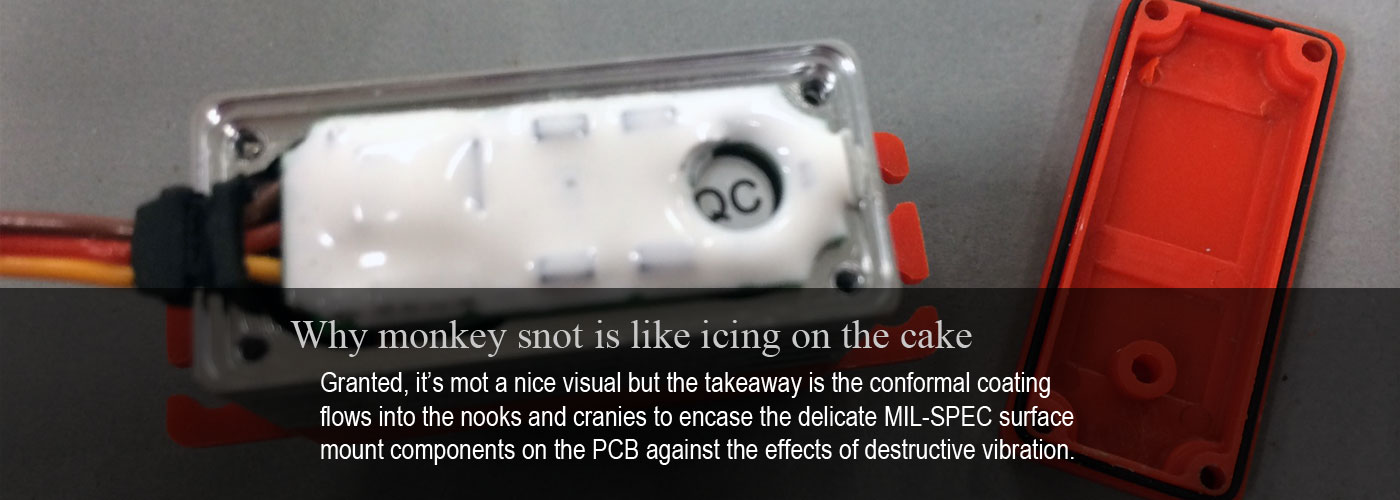

As you learn how well the DS180DLHV servo is made you might reasonably expect this to be our most expensive servo, but it's not. Instead, this is our best

general purpose servo. It's the servo that expert modelers select for a wide variety of sport and scale models. For example, savvy pilots - ones who grok what Eastwood meant (in the role of Callahan in Magnum Force) when he said, "A man's got to know his limitations." - will opt to use these for models as large as a 120cc gasser. Especially when they're intended for sport use versus 3D. For example, for performing old-school aerobatic maneuvers like loops, point-rolls, stall turns, as well as occasional snap maneuvers and Lomcovák.

Ever taken a servo apart? The metal gears rotate on steel shafts. The end of the shaft fits in a hole in the case, what's called a pocket. In cheapo servos, the steel fits into a plastic pocket but in a ProModeler servo, there's a brass insert reinforcing the plastic. When you pay a little bit more for a ProModeler servo, this is part of the reason why. As long as it moves, we know modelers won't throw anything away . . . so we produce ProModeler servos with the expectation of a service life measured in decades!

USE CASES:

So who uses these servos? In light of the MIL-SPEC and MIL-STANDARD test methods, you won't be surprised to learn the government has driven a lot of our product development. They're our biggest customer. So are universities, plus commercial UAS operators in agricultural and pipeline inspection ops. We've branched out to the civilian world, so our customers now include hobbyists.

This customer is often a highly experienced modeler, but also includes savvy beginners who realize just because the servo will first be used in 40-size trainer doesn't mean you throw them away when you transition to a higher performance model. Anyway, you may use this servo in a wide array of sport and scale models - with wingspans ranging from about 48" on up. And when we say 'on up', we're not kidding because the models in which the DS180DLHV may appear can be spectacular!

For example, look at the photo below. This is a scratch built (meaning the plans began as a blank sheet of paper, and every rib, former, stringer, longeron, leafing and trailing edge - everything except avionics, engines, etc. are built from bits and pieces). This, versus coming out of a box pre-assembled or from a kit! Anyway, this is a model of the WWII Bristol Blenheim. It weighs in excess of 44 pounds! Just look at the details - like the rivets, the pitch change mechanism on the dummy props, venturi which on the real aircraft powers the turn and bank indicator (and other vacuum gauges). Peer inside the cockpit and recognize the work of a master modeler, a pro's pro. Then consider the work of years has been entrusted to DS180DLHV servos. And while it spans more than 144" and weighs more than 46 pounds!

This master craftsman also groks servo selection. In choosing the DS180DLHV digital servos he perfectly demonstrates understanding of the requirements based not just on how large and heavy the model is, but on how fast it flies and the size of the control surfaces. Most importantly, because this is a one-of-a-kind scale model involving years of effort and planning, we are humbled that he's put his faith in ProModeler servos. Do you think he understands the difference between what something costs versus what it's worth? There's a lesson in this.

SUMMARY:

At heart, servos offering 180oz-in of torque and transiting in the 0.17sec/60° range are fairly common. It's the sweet spot in performance for most manufacturers. We believe finding another that offer everything these do is impossible to the point we believe there isn't a better servo - for the money - on the planet. Period. No other servo offers this level of power, precision, quality, plus tank-like durability (and nobody else lets you completely rebuild them yourself). So if you're an experienced modeler, and if you are mechanically 'ept' this is yet another consideration (if you can do basic soldering but naturally, you can also send them to us for R&R if you aren't comfortable doing these things).

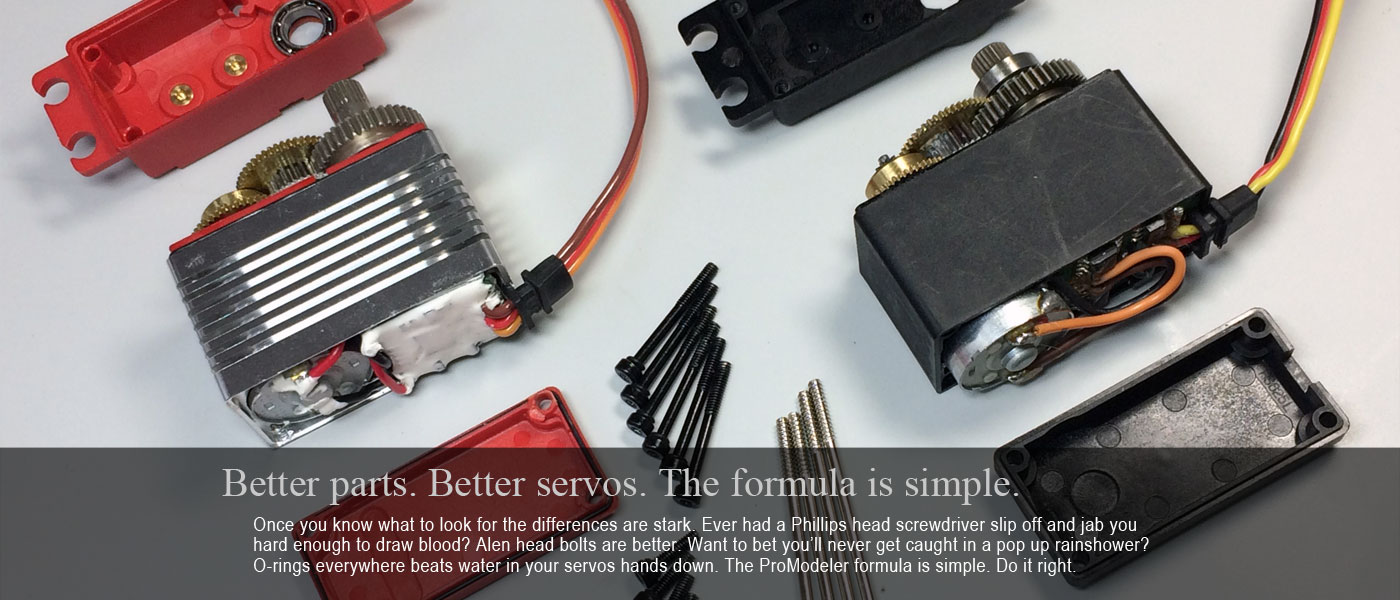

Better components. Better servos. The formula is simple. Decisions regarding what goes into ProModeler servos aren't made in accounting to optimize price and profit, but in engineering. In light of what goes into it - we believe $40 is a pretty reasonable price and we hope you agree because. Simply put, this is the best servo available for the money. Add a set to your cart. Do it now because you're going to love them!

Other Resources

For detailed specifications and dimension drawings, select the Specs tab above. Also, there's an even-handed look at the competition in the Comparison tab. Meanwhile, TL;DR is chock full of nitty-gritty details - where we disassemble and show you this servo side-by-side with a popular competitor. If you love delving deeply into stuff some find too tedious to read, don't overlook this tab.

Note: operating voltage is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo instead of a BEC. This is because LiPos deliver the required current without voltage spikes, noise, or otherwise adversely affecting the delicate avionics (25C or better is recommended). After all, synthetic orange colored Tang may have gone to the moon, but it doesn't compare to freshly squeezed orange juice. Same thing when it comes to feeding your avionics!

When customers mention a competing servo, they're basically asking our opinion regarding how it compares to our DS180DLHV. What follows is a summary of our observations. This is offered in hopes of informing your opinion while at the same time trusting you'll judge us to be blunt . . . but fair.

The workhorse of the servo industry are standard-size digital-servos equipped with 3-pole Fe-core motors. They're used for everything from 40-size trainers through giant scale models. Thing is, figuring out which servo is best can be hard because there are so many similar servos on the market. The purpose of this page is to compare and contrasts the ProModeler DS180DLHV digital servo with other high quality servos. That said, this isn't a comprehensive market survey because we're not including what are, in our opinion, junk servos.

This, in part is because we're modelers like you. Thus, we place a high value on our models. But it's also because we've been at this long enough to grok the the real risks posed by servo failure resulting in an out of control model. look, there's no nice way of saying this but when a nice ARF model costs $200-300, an engine is $125-200 (or motor, ESC, plus batteries are $250), and four good servos are about $160, while we understand there are some who want to believe they can get good servos for $60-80, we just don't agree. That said, there's obviously a market for $15-20 standard-size digital-servos. Thing is, once we eliminate what makes our servos better (just to make them cheaper), we're not willing to put our name on it. Bottom line? The servos presented are ones we'd consider buying for our own use if we weren't in the servo business.

Finally, please note; because we don't hide from good competitors, while some of these cost more and others cost less than ours (and some actually outperform us in some manner), we nevertheless show them because we believe you'll judge ours are, on balance, the better servo for you. Anyway, servos are listed alphabetically.

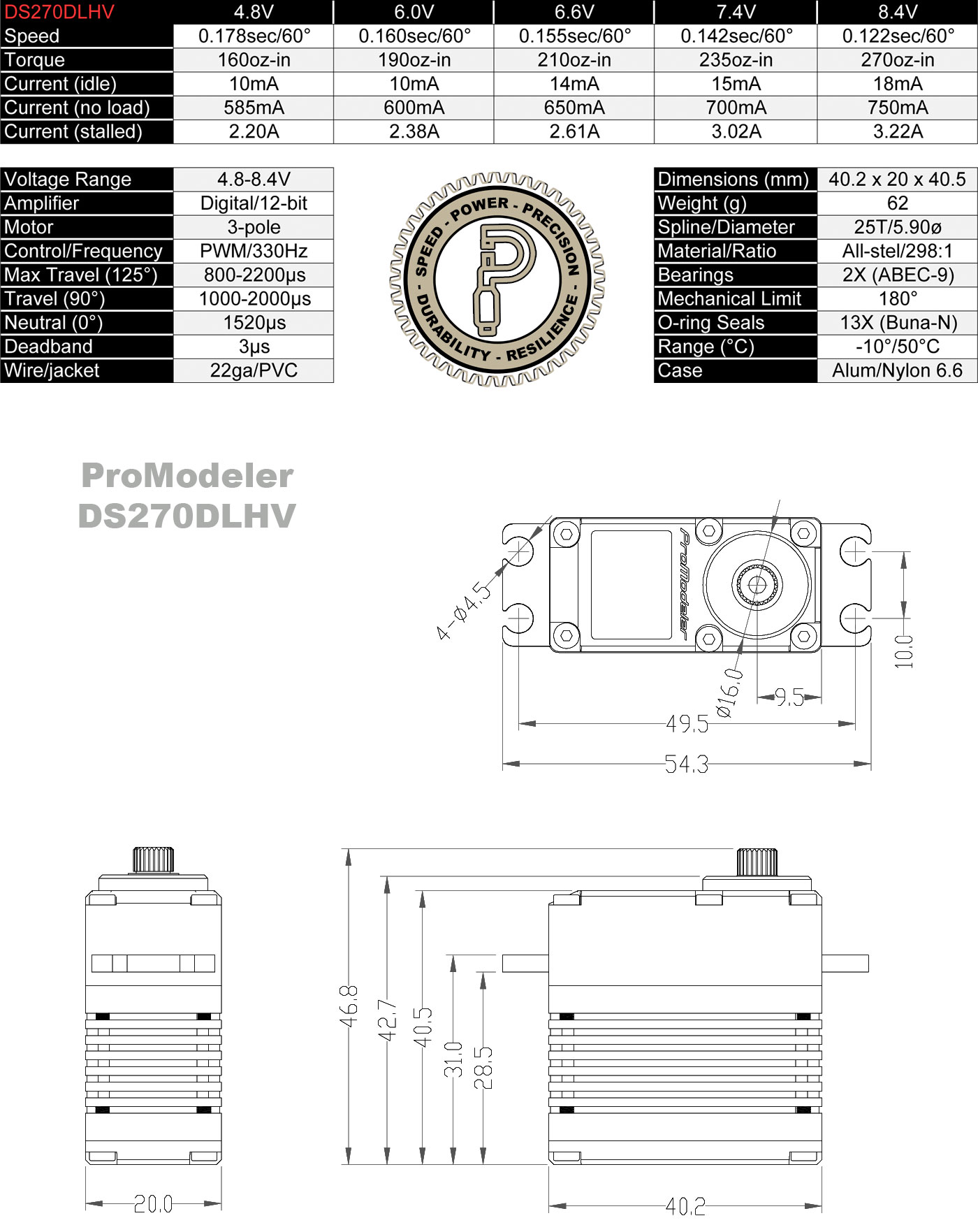

- Futaba S3071HV - $49.99

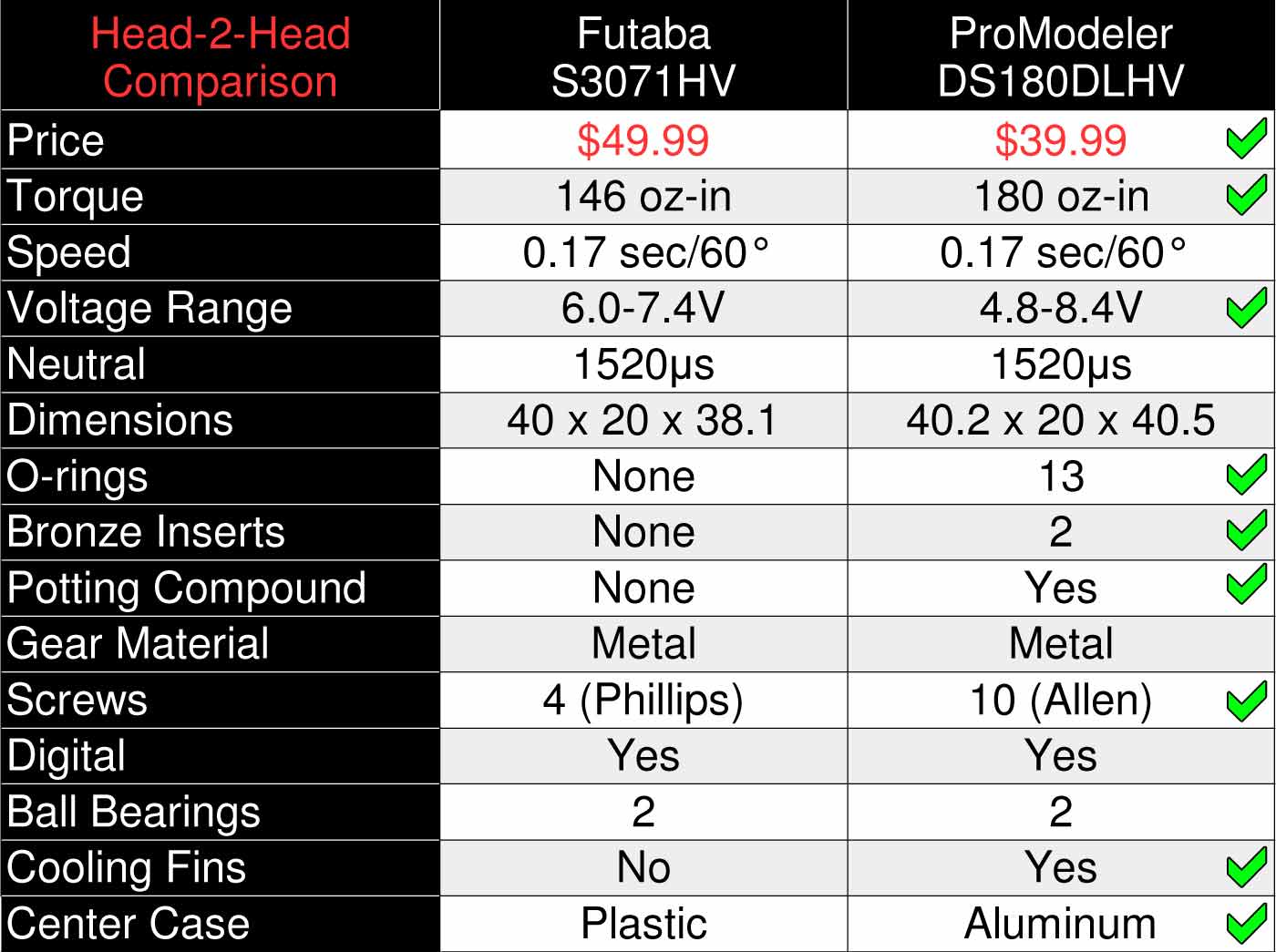

- Hitec HS-5645MG - $39.99

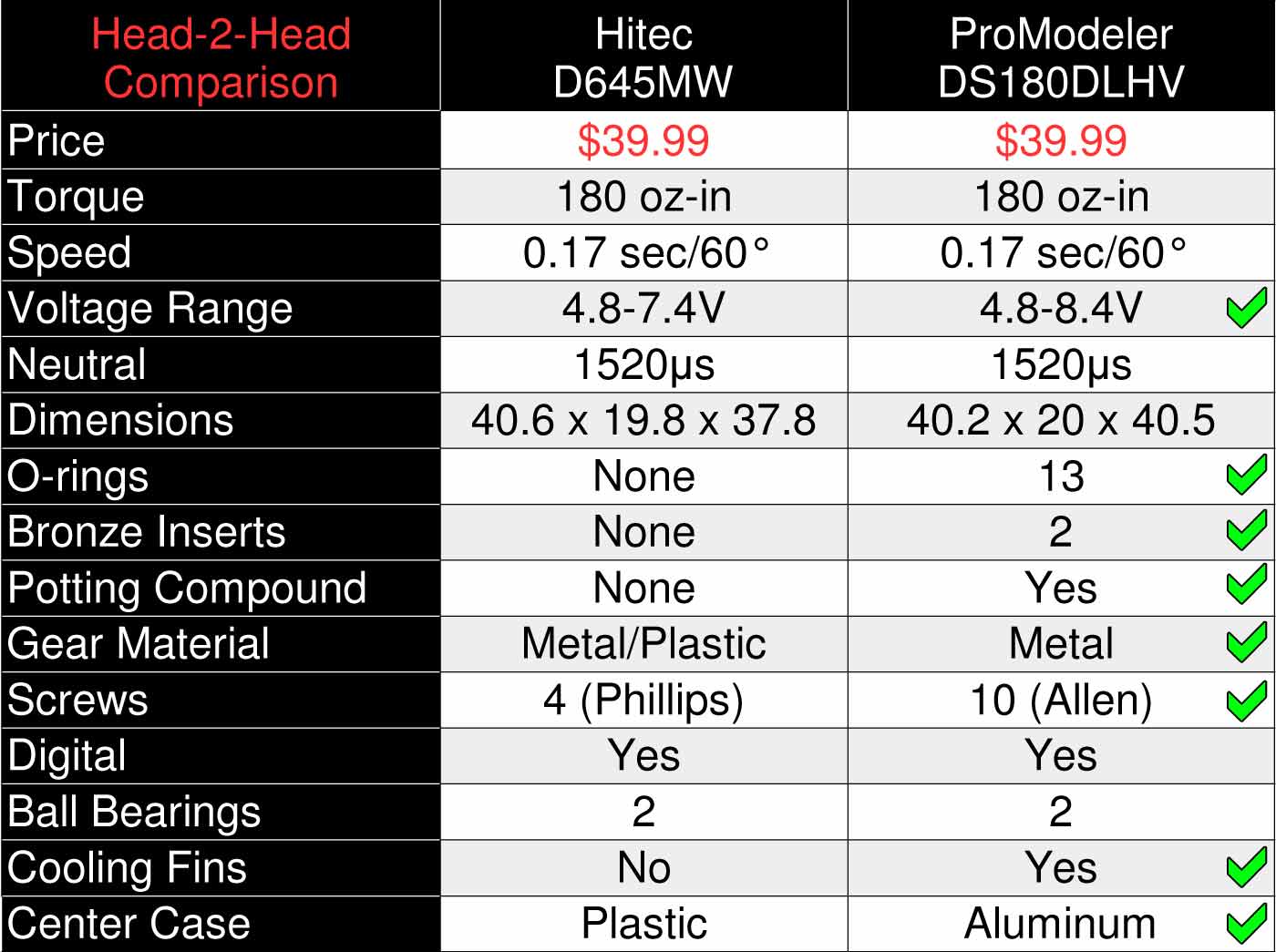

- Hitec D-645MW - $39.99

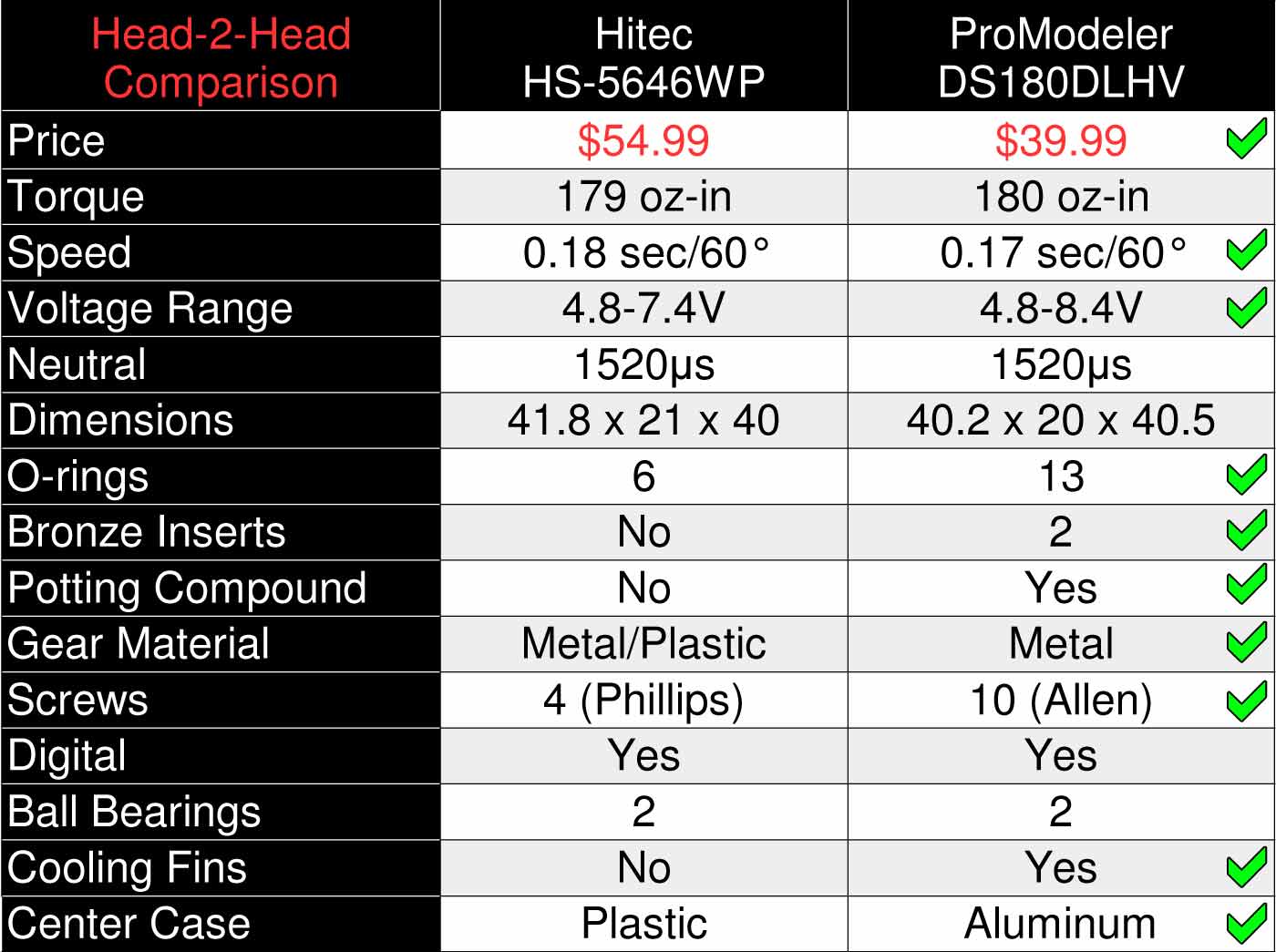

- Hitec HS-5646WP - $54.99

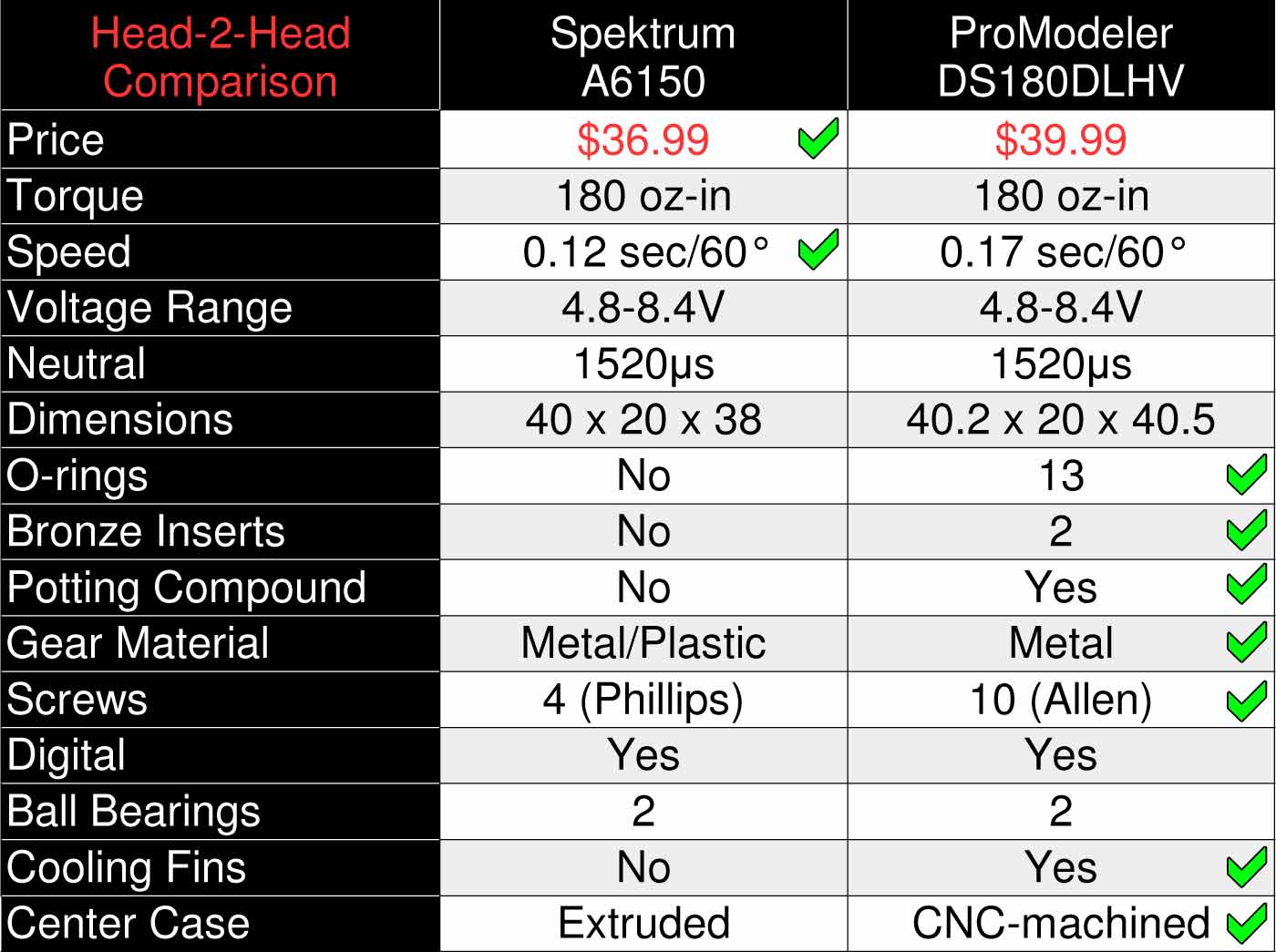

- Spectrum A6150 - $36.99

First up is Futaba's S3017HV. As modelers we've had a lot of experience with Futaba-brand servos. They're well built and reliable. The S3017HV upholds the tradition. Sure, theirs touts S.Bus as a native feature but we counter with a) if you're not smart enough to plug a servo into the appropriate channel of your receiver you have bigger issues to worry about and b) they offer adapters for non-native S.Bus servos so it's our opinion; for the vast majority, it's just a gimmick. Meanwhile the DS180DLHV offers more torque, the same speed, and costs less, plus we feel ours is built better.

Here's why; they fit the steel gear shafts directly into a plastic pockets (within the top case). we designed bronze inserts to reinforce our plastic top case. This is important because the useful working life of a servo can easily exceed 10 years. This means the question of which servo will still be nice and tight is a no-brainer.

Similarly, Futaba decided 4 screws was good enough to hold it together. We, on the other hand use 10 because we achieve a stiffer assembly. Stiffer is better for keeping the gears in perfect mesh even under high loads. Again, something of a no brainer. Added to which, instead of Phillips heads, our servos use Allen-head screws.

However, a key difference is Futaba rely on a plastic center section for this servo while we believe you get more for your money with a center case that's CNC-machined from a solid billet of 6061-T6 aircraft aluminum. You get cooling fins too because these help with dissipation so the motor lives longer when the servo is being worked hard.

Then there's the PCB (printed circuit board) which we protect against vibration with a conformal coating (eyeball the detail photos within the TL:DR tab). And to protect against environmental intrusion, we seal the DS180DLHV with thirteen (13) O-rings (versus none for this Futaba servo). Bottom line? Experienced modelers judge the ProModeler servo to be made better - and if you do too - then it's game, set, match!

The Hitec HS-5645MG has been around a long time. In fact, there's a reasonably good chance you can see one at any model flying field in America because it's such a darn good product (and FWIW, this was our internal benchmark when designing the DS180DLHV). To the point both theirs and ours offer about the same torque and speed, and they even cost the same! That said; we believe ours is better.

Here's why; to begin ours is more versatile because it can be used with a wider range of input voltages. It also has O-rings for water resistance - important when you're dodging rain drops from a pop up rain shower one fine summer day (or perhaps enthralled by float planes and re-purposing your servos for flying off water three years from now).

But what about the programmability Hitec touts? Well, since you can reverse a servo and set end points, etc. within the transmitter we fail to see why it matters that you can also do it within the servo. Basically, it just isn't that big a big a deal - not like it was back in the day when transmitters were primitive. Not that it's totally useless, but is it sufficient reason to justify buying what's ultimately, considered by many an inferior servo?

Here's what we mean; beyond water resistance and a wider range of input voltages, the DS180DLHV has an aluminum center section for better motor cooling. It also uses 10 Allen head bolts for assembly instead of Phillips head screw. Added to this, it has a conformal coating on the PCB for better protection against vibration, and the plastic top case has bronze inserts which reinforce it where the steel gear shafts fit (theirs fit the steel shafts directly in plastic).

Add one last thing; when did it become OK t market MG (metal gear) servos with a plastic gear? We mention this with respect to the HS-5645MG because their 'metal' gear train includes a plastic gear! It's their part #55016 and FWIW, they're sold in 3-packs (for whatever that tells you regarding its durability). Anyway, while it's still being offered brand new, it seems even Hitec realize its day is passing because they're making newer versions, the D546MW and the HS-5645WP - but more about them later. Below is the Head-2-Head match-up between the DS180DLHV and the HS-5645MG and quite frankly, we believe we run away with another win!

With the D-645MW, the torque of the Hitec digital servo remains about the same as the earlier generation HS-5645MG but they kicked the speed up a notch - to match ours exactly. Not, if we're being honest, that there's a heck of a lot of difference between 0.18 and 0.17sec/60° (6%). The biggest benefit most will realize with the D-645MW is the ability to run off a straight 2S LiPo at 7.4V (nominal). This is nice but we still score a win in this category because the DS180DLHV lets you operate off a much wider range of input voltage (from 4.8 to 8.4V).

Otherwise, for all intents and purposes, while this is a very nice update to the HS-5645MG it's by and large a very similar servo (reflected in the cost, which is the same-same between this one and their older design - and ours). Frankly, we suspect few would see anything worth crowing about because once you consider the conformal coating on our PCB (for improved resistance to vibration), the much stiffer 10-bolt case (plus Allen head bolts vs. Phillips head screws), as well as the 13 O-rings for sealing, and especially the CNC-machined aluminum center section, which lets a motor run cooler (for a significantly longer lifespan when a motor is worked hard) it's just no contest when the cost is the same. Especially considering how just as with the HS-5645MG, the D546MW has a plastic gear within the gear train (same part number).

Next up is the Hitec HS-5646WP. It's another standard-size digital-servo in their vast lineup and it more seriously competes with the DS180DLHV because it's waterproof. This is great if you ever develop a interest in flying off water, believe us. Flying off water is almost as much fun as sex (just kidding, but barely). Meanwhile, performance is about the same-same as their other versions (and about the same as ours). Yes, the speed drops a skosh (6%) but this isn't anything worth writing home about. They even keep the plastic gear within an otherwise metal gear train (once again, same part number).

However, there's a rub. Hitec wants this servo to go back to their service center any time you need the little plastic gear (or the case). Remember, they sell the plastic gear in 3-packs so it wouldn't be unreasonable to conclude it's somewhat fragile. Add in for postage (plus the delay before you get it back from their service center) and you better think long and hard about getting married to this servo. Especially because this one also commands a hefty price premium of $55 vs. $40 (28% more expensive). This isn't quite 3-servos for the price of 2 but it's close.

On top of all this, theirs sports an all-plastic case, no conformal coating, and no bronze inserts for reinforcing the case where the steel gear shafts fit the pockets and once again we believe the DS180DLHV wins (going away).

This brings us to the Spektrum A-6150, which is another worthy competitor to the DS18DLHV. It outputs the same 180oz-in as the DS180DLHV but it's faster, which can be important for some applications. It even has a metal center section plus it's 3 bucks cheaper! Better deal? Not so fast!

Let's begin with the gear train. They say 'metal' but if you investigate, it's metal and plastic (look up their part #SP1003). And there's a catch because according to their website the gear set won't be available until sometime in 2018 - hmmm. Conversely, when we say metal gears we're not bullshitting you. Plus replacement gear sets are available if you want them without waiting.

Next, let's discuss the metal center section. Theirs is an aluminum extrusion (formed just like a window frame is squeezed through a die - exact same process). And it doesn't have cooling fins. Ours? We begin from a forged billet of 6061-T6 aircraft aluminum and CNC-machine it to the final form - complete with cooling fins. Why is this important? Basically, the servo motor will last longer (when the servo is being worked hard) because the fins help it shed heat faster. Maybe this doesn't matter to you, but there are other factors that may.

For example, instead of four long Phillips head screws, which totally bypass the aluminum because their extruded aluminum center is merely sandwiched between the plastic bottom and the plastic top pieces (that's right, the screws thread into plastic), our aluminum center has ten holes tapped for fine-thread Allen head machine-bolts. Thus, the center case of ours is the foundation to which the plastic pieces attach. Do you grok the difference? Our servo is a Hell of a lot stiffer meaning that under load the gear mesh doesn't vary - at all. Especially because we us 10 vs. 4 screws (to say nothing of Allen being better than Phillips heads). But there's more.

For example, the metal gears are fitted to steel shafts, right? These tiny steel shafts fit into plastic pockets within the servo top. Over time they become egg shaped due to the loads being imposed. They sell you a replacement case (we do also) but our plastic bits are better because we reinforce the gear component with bronze inserts. Why? It's because as experienced modelers know, the working life of a servo can easily exceed 10 years. Since the bronze inserts are much harder than plastic (meaning they won't wear away like plastic) this means you can depend on a much longer service life. Is this worth an extra three bucks? It's your call but we think this is something of a no-brainer because what if you can't find parts for their case in 10 years? Just saying.

Bottom line? These days metal gears doesn't really mean all-metal, and all servos with an aluminum center case aren't equal, either. Basically, today's marketing guys practice a sharp form of word-smithing that means you have to be careful, or put another way, all that glitters isn't gold!

In closing, unlike hobby-grade servos, the DS180DLHV servos are built to a higher standard. They meet MIL-STD-810G-Part 16 (Vibration) Test Method 514.6 as well as Test Method 516.6 (shock) because like you, we know all about impact from crashes and engines vibrations that propagate throughout an air frame! This is why our PCB (printed circuit board) has a conformal coating (potting compound in the civilian world), it's why we reinforce the gear case with bronze, and it's why we CNC-machine the center from aircraft aluminum. You won't find this level of detail in the above Spektrum servo, or the ones from Hitec and Futaba. When we suggest ours is built better, we back it up. It's your money, choose wisely.

A $40 DS180DLHV costs about $32 to make. A good quality competitor like a Hitec D645MW also sells for $40 - while costing maybe $7. The reason a $7 servo sells for $40 is due to a business focus on making and pricing a product with a business model that prizes putting the product on display in the local hobby shop. We figure folks would rather receive more servo for their money and buy off the internet. It's why Amazon succeeds. Same with us and thus, instead of ponying up for a US-importer, who sells them to a distributor, who sells them to hobby shops, who in turn sell them to you (e.g. such that everybody gets a cut while you pick up the tab), with ProModeler you're dealing direct!

Of course, this isn't rocket science. The Hitec is a pretty good servo but realizing how the game is played thrifty modelers buy off-brand metal gear servos for about $14 because they receive pretty much the same as the $7 servo (thereby paying about what the US distributor would pay). So while cheapskates are taking a risk of buying junk, and cautious modelers reflexively buy what they've always bought, the astute see the obvious - we spend 4X more on making a servo - and because they're not afraid of trying something new we gain converts amongst the savviest modelers.

Thus, if you prefer a better servo to a cheaper servo, then for the same $40, you get a Hell of a lot more servo for your money. Better components. Better servos. The formula is simple.

Better components. Better servos.

Most of us have felt that lurch of panic as we dropped a servo during installation before we snatched it off the floor to inspect for damage. It's this shared experience as modelers, which led us to build the DL-family of servos to an aerospace-standard.

For example, to better mitigate against shock (and vibration), we use what the military refer to as a conformal coating to protect the delicate electronics components mounted on the PCB (printed circuit board). Compared to the square of foam rubber used in hobby-grade servos, this is much better because it gets in all the nooks and crannies between components. We call the white stuff smeared over the electronic components monkey snot because it's such a sticky mess to deal with during application.

Anti-vibration and impact protection are a big deal to our military customers. Perhaps you aren't flying a million dollar UAV, but if you simply want better servos for your pride and joy, monkey snot is one reason they rely on ProModeler servos.

Also important is how we use MIL-SPEC components - plus the best motor and potentiometer money can buy. These are critical for the best centering performance possible. Yet nothing is quite so telling as this simple fact . . . you can actually buy these components from us. While hobby-grade servos offer cases and gears, for all else you have to return it for service. ProModeler is different because we make these components available.

Considering sport pilots probably don't fly enough to wear these components out in a decade, who are these spares for? Typically competition pilots - ones who get in 4-5 practice-flights after work 3X a week (plus the same, or more, on weekends). These guys fly so much they require PM (preventive maintenance) once a year. If your winter-project list includes returning your servos for R&R, but you can make three solder joints as well as the factory technician, then you can save money with ProModeler servos because we know DIY is a big part of the hobby. Making internal replacement parts available, so you can bring your servos up to snuff without breaking the bank, is a benefit competition pilots will especially appreciate.

Beyond helping you restoring your servos to like-new performance by making internal components available, do you believe in better engineering? We do too. Unfortunately, unless your hobby dealer lets you open it up to look before buying, the other guys don't make it very easy to know what you're actually getting. Anyway, if you appreciate attention to detail, yet another thoughtful touch (one that ensure your investment in these servos delivers value) are the bronze bushings reinforcing the gear shaft pockets.

To recap, not only is the molding for the polymer pocket more robust on our case, but the bronze inserts reinforcements are there so your servos will last, and last, and last! Bottom line? Understanding the difference between something's price and its value comes down to grokking the details.

Along the same lines, a big difference for why experienced modelers prefer ProModeler servos and something priced about the same is found in how the center section is made. One the one had an injection molded piece, on the other one that's better because it's made of aluminum so the motor cools better when you're working the servos hard, has cooling fins for shedding heat more quickly, and is drilled and tapped to accept fine thread machine-screws for the ultimate in rigidity.

Finally, eyeball all the major components laid out side-by-side. We suspect it's rather easy to see why your next set of servos should be from ProModeler. If you're especially sharp eyed you'll have noted the assembly uses 10 Allen-head bolts with machine-threads instead of 4 Phillips head screws with cheese-cutter threads. You'll see how each has an O-ring - and - threads into aluminum instead of plastic. You also also know to look out for gears represented as metal but which include a plastic gear so fragile they sell replacements in 3-packs. You also understand that servo manufacturers that shove a cheap piece of foam beneath the electronics cover and call it good aren't just shortchanging you, but playing roulette with your model by paying less than perfect attention to vibration protection.

As you get a better idea of what to look for, you buy smarter. It's as simple as discerning the differences between hobby-grade and professional-grade. So let's tie it all together. Better parts. Better servos. The formula is simple. It's a no-brainer and paying the same, or more, for another brand just because it's what others do is a non-starter with savvy modelers. You've found the servos you want for your next model.

Overall Customer Rating of 4 Reviews: