We've parked a standard size DS635BLHV next to the low profile DS490BLHV servo (both share 20mm x 40mm footprint) to show off its svelte low-profile design. So if you're looking for a standard class servo with a lower profile than a conventional servo (perhaps for wing-mounted applications or 1/10th scale carpet racing) then this is a very rugged alternative to the usual suspects in the class. Maybe one you'll judge best for you!

Let us show you a little more about it . . . beginning by juxtaposing it with our DS635BLHV.

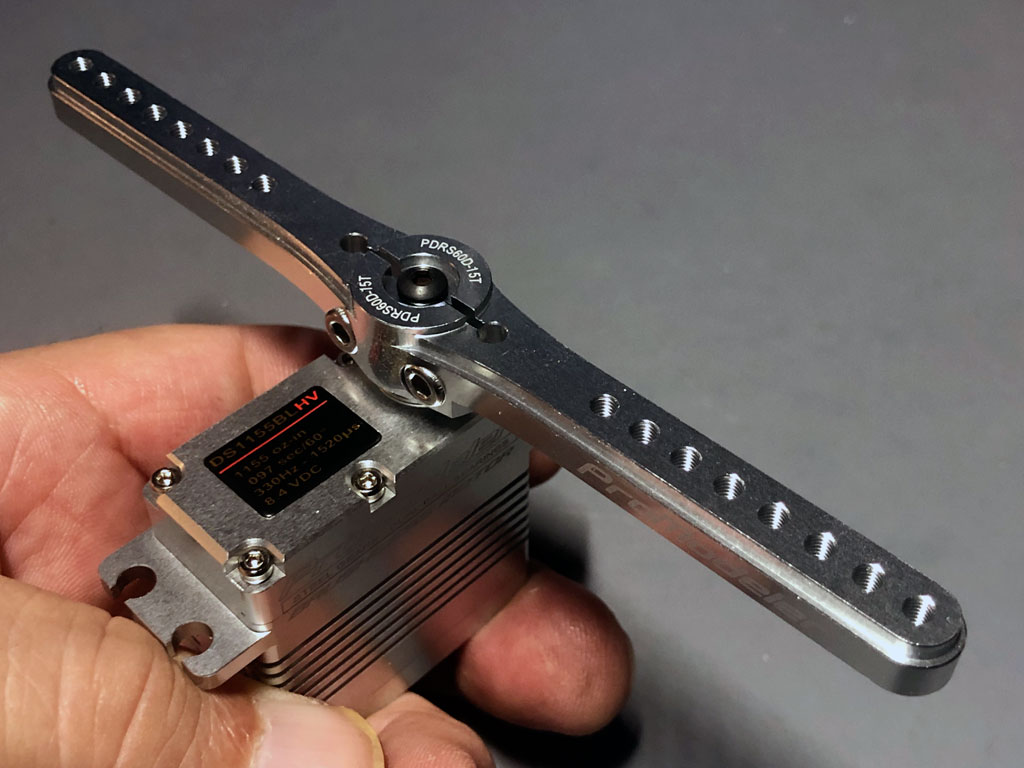

Perhaps you noticed the beefy 15T spline (ø8mm). Reason we went to this is because servos have become so powerful with the new class of neodymium magnet motors that 25T splines were twisting under the loads. Even using the best steel in the world, they just aren't holding up in some applications!

Eyeball this brief article showcasing the process of gear repair for our conventional DS505BLHV, a 500-oz class standard equipped with conventional 25T spline output shaft (ø6mm), to better grok what we mean.

Anyway, we resolved the shafts twisting under extraordinary loads by turning to our +2685oz-in quarter-class servos and borrowing the gnarly spline off one of those. This sorted the issue.Totally.

Here's a nice comparison photo showing how they look side-by-side.

- Conventional 25T output spline versus gnarly 15T super duty

Naturally, you're probably wondering about available servo arms, right?

Servo arms

We've got you covered with a nice assortment of 15T spline servo arms. As usual, clicking the link opens a new browser page so you don't lose your place here. The arms range in length from 1" (25mm from center) through monster 60mm long arms (2-3/8"). We even offer them in double-side configurations like this one.

And take note, these are threaded for M3 hardware and we CNC-machine them from a solid billet of 7075-T6 aircraft aluminum. Plus, they're

beefy enough to make double nutting the ball screw a thing of the past!

Furthermore, we also produce several fork arms (where the ball link is captured top and bottom).

Model numbers

If you're wondering what our servo model numbers mean . . . you don't need a decoder ring, it's actually something understandable in English;

- DS = Digital servo

- xxx = torque rating in oz-in

- BL - Brushless motor

- HV = High Voltage (to 8.4V)

Moreover, part of what makes a DS490BLHV better than what our competitors offer you (beyond torque and speed) is unlike hobby-grade servos, it's built to meet military standards (and subjected to these tests).

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

Bottom line? When it comes to servos . . . they aren't built any better by anybody on this planet!

Basic specs (open the specifications tab for the detailed specs)

- 490oz-in of torque

- 0.078sec/60°

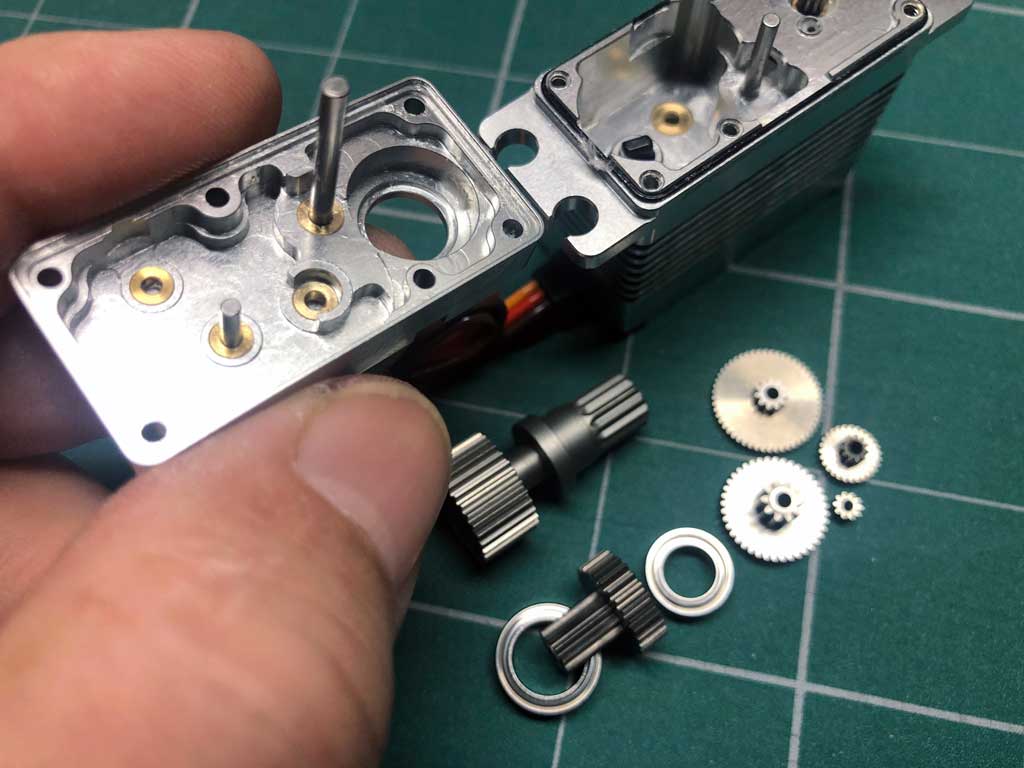

And with regard to how the internal build qualities compares? I know it'll be hard to figure it out because our competitors don't disclose how theirs are built (meaning by showing photos of their guts like we do). But maybe this photo will clue you in regarding how ruggedly built ours are because we don't hide what you're actually getting by only showing you a pretty outside.

After all, as it turns out, your Mom was right . . . beauty really is more than skin deep!

Speaking of beauty, maybe you'll also appreciate the parts making up our servos, which we buy instead of make. These include the best Japanese brushless motor we can lay hands on. If you're unaware, these last 5X longer than competing coreless motors. And if you don't know diddly squat about the kinds of motors found inside servos, review this article to learn more:

Also, your DS490BLHV is equipped with durable all-steel gears (instead of anodized aluminum alloy or titanium). Curious which is better? Well, this really isn't rocket science and you don't even need to be an engineer to realize steel is stronger by a country mile.

Sure, marketing types love using terms, which see the inexperienced reflexively reaching for their wallets (like titanium and carbon fiber) but we suggest just using your eyeballs Mk II. This is because if you check out what the money-is-no-object racing teams like Ferrari in F1 or Ford and Chevy in NASCAR rely on, their transmissions use all-steel gears - just like ProModeler.

To this add dual ball bearings plus the world famous Japanese Noble 1mc potentiometer for superb centering.

Magic

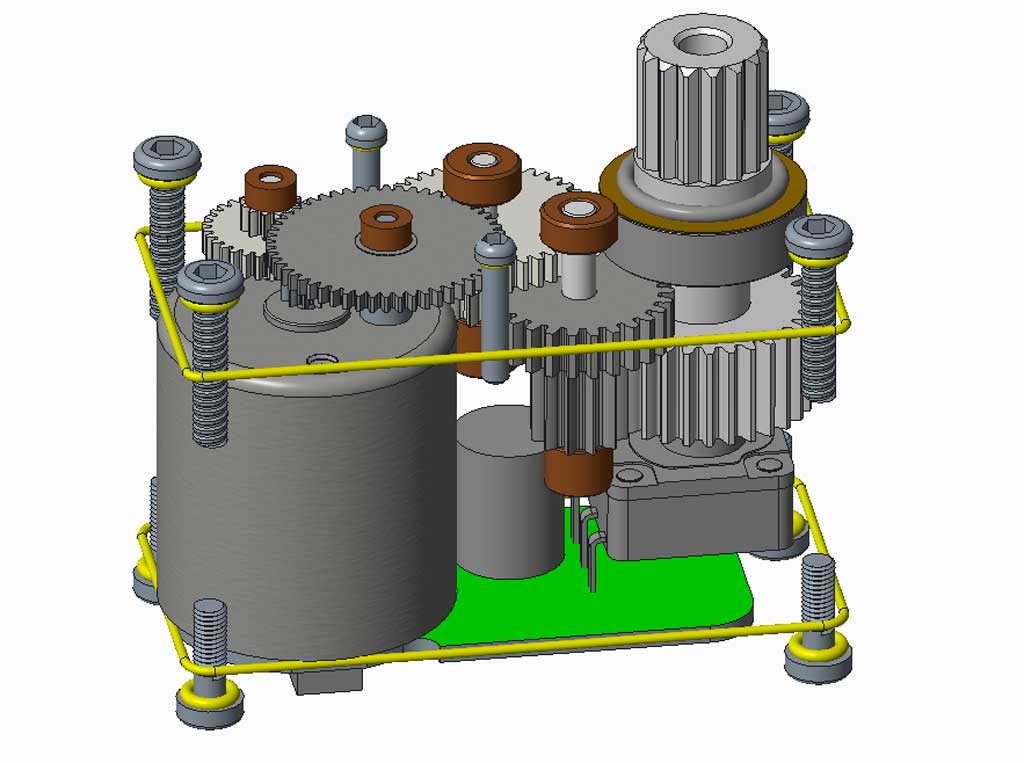

So where's the magic in this servo? It's in the design of the gear train that allows us to stuff much larger gear surfaces into a standard size footprint because all things equal . . . bigger is better when it comes to gears.

- Yellow are o-rings and the bronze bits anchoring the gear shafts in the alloy are shown in brown.

This DS490BLHV goes head-to-head with products of similar dimensions and purpose like;

. . . and all of these links open in a new tab so you don't lose your place.

So which servo is best for you? Ours or one of these? Well, the answer as always is . . . it depends!

On what? Like what's more important to you, naturally! Maybe it's torque, speed, price, or build quality. Dunno because we're all different so we emphasize different things. We just hope you judge ours as best for you application and if so, we welcome you to the ProModeler family!

Note; if a link's broken, tell us:

info@promodeler.com because your heads up lets us fix it with alacrity.