Folks are always asking, 'What's the beast servo for my Arrma Mojave 6S? That's their 1/7th-scale desert rig, and of course, we also get calls asking the exact same thing about the smaller 4S-powered 1/8th-scale rig. This 4S rig is probably better off being the subject of a separate article but for now, we won't shy away from ideas for it, too. So here's the thing, the answer to what's the best servo is always . . . it depends.

Depends on what?

Principally on you and how you drive. Obviously, that, and size matters, too. So whether it's a 6S, or a 4S rig, what's actually most important is 'you', you are the critical factor. It's your needs, expectations, budget, etc. that matter the most. However, while rig-size matters, because both take the same size standard-class servos, then there are many similarities *and* it's defensible to yak about both within this article.

Meanwhile, another important factor is; will it stay stock or be hopped up to the moon? The more alloy you add, the heavier the rig gets and hot motors make them faster and faster. Means needing not just a stronger servo to turn the wheels, but a large rig like this that's fast and heavy eventually gets to the point you need a servo that's more ruggedly built, too.

Strong because of the equation for force, which equals the mass X the acceleration, or F=ma and this matters when you're cooking along at speed and cut the wheels. Better known as Newton's 2nd law, the servo has physics to contend with and shifting the vector of acceleration is harder with the heavier and faster rig. In fact, absent the servo, Newton's 1st law dominates, meaning it wants to keep going in the direction it's been traveling.

Ever seen a bowling ball smack 10 pins that started off as 4x4 chunks of lumber? Sends them flying, right? Ball weighs maybe 16 lbs and is going 18-20mph tops. What's one of these rigs weigh and how fast is it going? See what we're dealing with. Steering one of the things is not trivial.

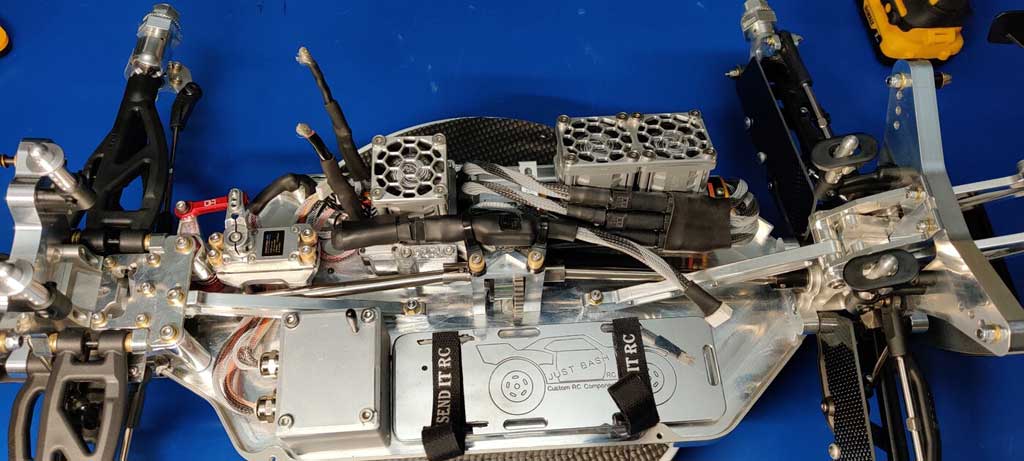

- Thoughtful component selection can result in an amazing Mojave

For example, we also get calls from guys who bought a 6S roller and because they were Jones-ing to stuff an 8S power system in it - like maybe left over from a Kraton K8S EXB, which they have already hopped up with an $1000 motor/ESC combo only to end up with a left over stock motor/ESC laying around in a drawer. So maybe they get to thinking about their 6S Mojave and go, 'Hmmmm, I wonder?', and then one thing leads to another! Presto, 8S Mojave is born!

That said, these particular guys are obviously more advanced than most of our customers with stock RTR moving into a better servo so when we speak about servos they're usually well prepared (like knowing they want a DS845 or DS1155), so basically just calling to confirm a few things before pulling the trigger. These are typically our buy once, cry once kind of customers because they already have the experience of buying Amazon-grade servos.

Don't know what I mean by this? Review this article where (because we don't hide from competitors) we put up one of our DS505BLHV ($100) against a $60 el cheapo, and then you'll be able to judge for yourself what's meant by the term - and whether it's fair.

Regarding 8S Mojave customers being more advanced, by this I mean they fully understand what's coming their way before proceeding down a path of increased maintenance when converting the rig. Meaning there's added maintenance, which accompanies keeping three 6S-sized diffs alive while a *lot* more power is poured through them, and they know it before deciding to go that route. Pretty expert modelers.

Moreover, quite often, these very folks are the ones who stuff our hairiest standard class servo in their Mojave. Servos like the DS1155BLHV, because they're also using big tires, maybe equipped with paddles. Interestingly, with some of them we hit it off like rum and Coke and because some have forgotten more than I know about the Mojave, they become a resource. Basically, a panel of experts to whom I can reach out and touch when I don't have an answer for a question someone's posed me. Anyway, we have yet to stump the panel and if we're being honest, 'I' learn a lot from them!

Also, while we're being honest, these converted 8S rigs always strike me as, *be careful what you wish for because you might get it'. By this, if I may mix my metaphors, you'll maybe discover the grass isn't really greener on the other side of that 6S-fence, but whatever, not my call.

Other factors in selecting the best servo for your needs include; do you strictly bash? Bashing out in the open, not crawling, and not jumping at a skateboard park, or ever taking it to a track because, after all, bashing is what this and other similar purpose rigs, like a Traxxas UDR, are made for.

But in fact, there are some of these things out on a track. And those are the guys who pony up for our faster servos, like the DS415BLHV, which I later will advise you to steer clear of in favor of another within our lineup, the DS505BLHV.

- This gorgeous EXB is the essence of the Mojave for the guy who wants to roll his own

Regarding RF and other electronic components

Then there's the question of RF-equipment, are you still running a stock Spektrum radio plus the stock ESC/BEC that came with the RTR rig? Radio is actually pretty OK but you don't get much in the way of current out of one of these things. The stock ESC-specs states 150A but this is for the propulsion-motor and they don't say squat about the BEC, and available control-electronics current - or at least not out front the way an aftermarket unit from Hobbywing, will.

This business of BEC-current is important the stronger you go torque-wise with servos because you can't make power out of thin air. So eyeball the servo specs to grok what I'm talking about if you don't understand what I mean. This is usually part of why many will recommend you upgrade the ESC because it also upgrades the BEC (because they realize the stock BEC won't cut it with a powerful servo).

Note; most 8S callers have opted for something like a Hobbywing Max5 but there's also the equally nice Max6 for the 6S crowd (although it *is* 8S capable). And if it's a Max5, then it's always interesting to learn if it's an 8S capable Gen1 or the 12S capable Gen 2? Or maybe something else altogether, like maybe from Castle?

- Hobbywing EZRun MAX6 V3 Sensorless Brushless ESC & Motor Combo w/4985SL (1650kV)

Anyway, RF-wise, it's also good to know whether you've upgraded from an entry level Spektrum SLT3 and the surprisingly decent S652 servo setup to what pros run, e.g. a Futaba 10PX, Futaba 7PXR, or maybe RadioLink RC8X. This information clues us in on who you are and how serious. Be prepared to tell us.

For example, we don't sell RF gear of any sort (Radio Frequency systems) so we don't have a dog in the hunt. By this, meaning our advice is unbiased by a desire to sell you a radio, take my meaning? Like it's our opinion a major benefit of the RadioLink is the TBS crossfire piggyback module for extreme range, but a hobby dealer who sells Spektrum certainly wouldn't tell you this kind of stuff, for the same reason he pushes Spektrum and Savox, instead of RadioLink, capisci? Anyway, if we know something, we will share it with you.

And of course, it goes without saying, knowing what servos you have *already* destroyed can help us help you. Be pointless to guide you toward a DS360DLHV if you've already destroyed a Savox 1210 since they have similar construction, take my meaning? Ditto a DS505 if you've already destroyed a Savox 2290, right? So once we know more about your level of experience, not just yours but with other products, then we can better gauge what you're probably needing servo-wise from us.

Finally, there's the ever present bottom line, meaning how much can you actually afford to spend! After all, it's kind of pointless to engage in mental masturbation with me when we're chatting about your needs. By this, I mean some guys call and get wound around the axle with what they're dreaming, to the point of convincing me they need one of our DS630BLHV servos ($120) only for me to subsequently learn they only have the budget for a DS360 ($50). That's kind of stupid, agreed?

- Note the powerful DS630BLHV right at home, like it was born there for the job

Point being, while a DS630BHV will take a you a looong way with a 6S rig, the DS360 is probably only suitable for a few 6S drivers, and is mostly suited for the 4S rigs (but not all of them, either). Honestly, only those with a 6S rig on a incredibly tight budget like, 'We just had a new baby and this is all I can afford', should reasonably consider the DS360DLHV in that class of rig.

Anyway, by not being straight with me, some guys just piss my time away, and no offense, but that's not fair because I do have a business to run! Major point being, if you want to engage in bench racing, then you *should* be doing that with our friends at ArrmaForum, instead.

That's where you'll get all kinds of advice but in general, it's good advice and if not, it's well meant (and someone else will put you straight soon enough). If the ArrmaForum is news to you, click the image to visit (opens in a new browser tab so you don't lose your place here) and join.

Click to open a new browser tab and join

Click to open a new browser tab and join

Bottom line?

So a simple question like, *What's the best servo for my Arrma Mojave?* quickly becomes complicated and honestly? There's only one right answer . . . it depends! So let's jump in and see where you might stand in relation to our servos.

So the other day a guy calls to chat about what's the best servo for his Mojave 6S. As it happens, I'd just had the same conversation (but via email) with a fellow that very morning. Since it was fresh in my mind, I was able to help him lickity split.

So what does a guy with an 4S rig need versus a 6S rig? Maybe something different, but maybe not since by definition, *all* standard servos will fit. What's different? Being lighter the 4S doesn't really need to throw as much servo at solving the servo puzzle. Anyway, after getting off the phone with my 6S customer, I jumped into my Sent Messages to dig out every message with Mojave within the body. Why? Simple, because these captured all my previous email conversations.

Point being, we offer a wide range of suitable servos, but there are so many possible Mojave variations, it can be hard to keep them all straight. So distilling the emails into one document served as crib notes before I settled in to write this caseSTUDY for the Arrma Mojave.

Setting the table

While we offer 15 standard class servos, there are only 8 of these I can reasonably recommend for you and your rig. All fit perfectly, so one of these may be just right for you, but which one is best? Dunno, let's see something about each and see what strikes a resonant chord with you.

Listed in order in increasing ruggedness, while sidestepping torque where BLS1 and BLS2 have an overlap with DS845 and DS930, these step-up in price sequence (generally getting more power and expensive, both), these are;

Other than price, maybe you notice there are four different series - DL, BLS0, BLS1, and BLS2.

With regard to the economical DL-series, while there are five of them ranging from 90-360oz-in, only the one (360oz-in) makes the cut. Similarly, of three BLS0, again, just one of those, the DS415BLHV makes the list. Then there are three BLS1 servos and three BLS2. The BLS2 are what we call the hairy brethren amongst ourselves, the bad asses. Cost the most, as you'd expect.

Servo horn and spline discussion

Because the first five use bog standard 25T output shafts, you can either order one of our PDRS25-25T horns, or use whatever came with the rig, or if you're feeling it, maybe order one of those steel 20mm Vanquish servo horns. Not sure you really need it but what the heck, it's a hobby and need has precious little to do with anything!

- The sweet 25T Vanquish horn mounted with the link at 20mm on to a DS630 servo

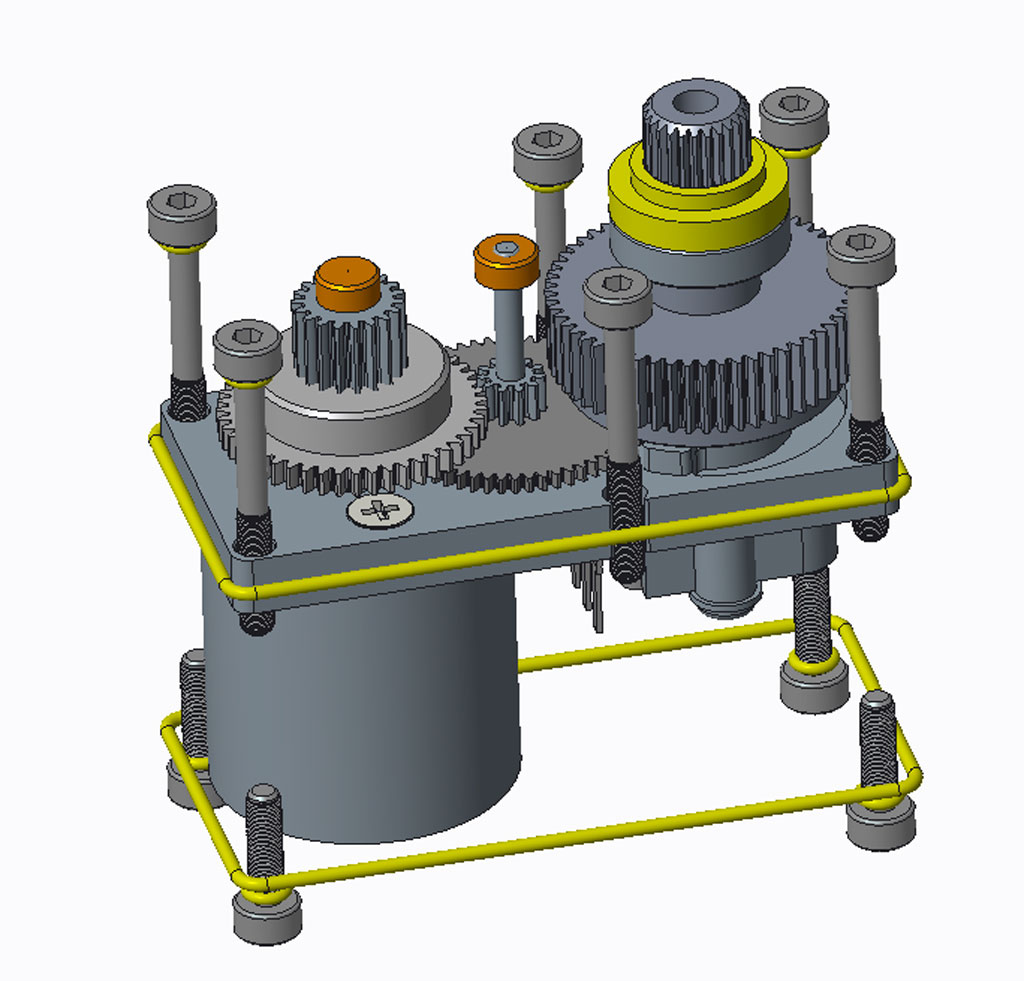

Now here's something you need to bear in mind, when we discovered trucks were destroying the 25T spline shaft, we looked into the parts bin to see if maybe we could use the ginormous 8mm, 15T spline shaft from the DS2685BLDP (yes, 2685oz-in).

Turns out with custom gears, we could although this also meant a larger output shaft bearing which destroyed hopes of an economical retrofit for older generations. So eyeball this image of a stainless steel output shaft twisted following impact. And that's not the worst we've seen, so more later because again, we don't hide from anything, even things that may be misinterpreted without explanation!

- Yes, this 6mm, 25T output shaft is twisted . . . stainless steel not some bullshit titanium

25T vs 15T

Point being, for the ultimate in ruggedness, we abandoned the 25T spline everybody else uses (even us through BLS1 servos) and once you step into BLS2 series servos, now you get a whole different animal servo wise.

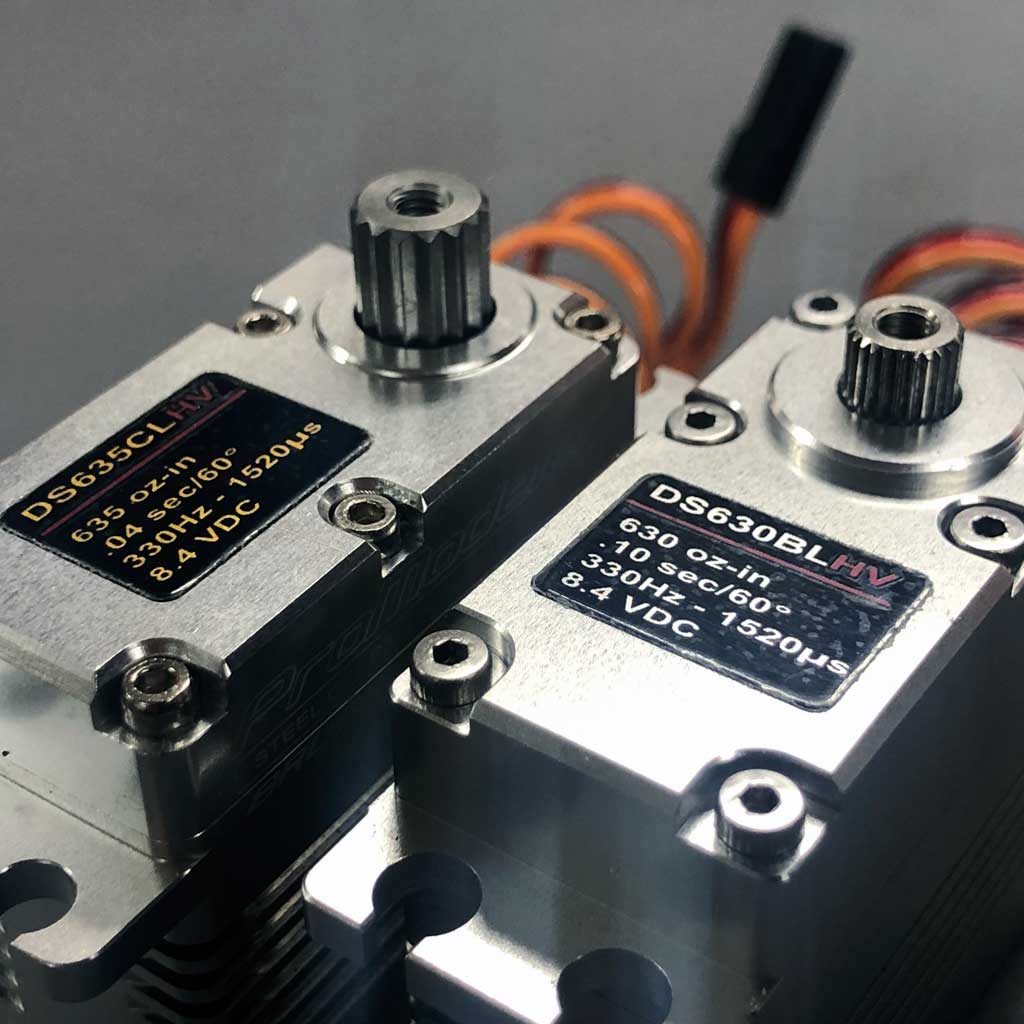

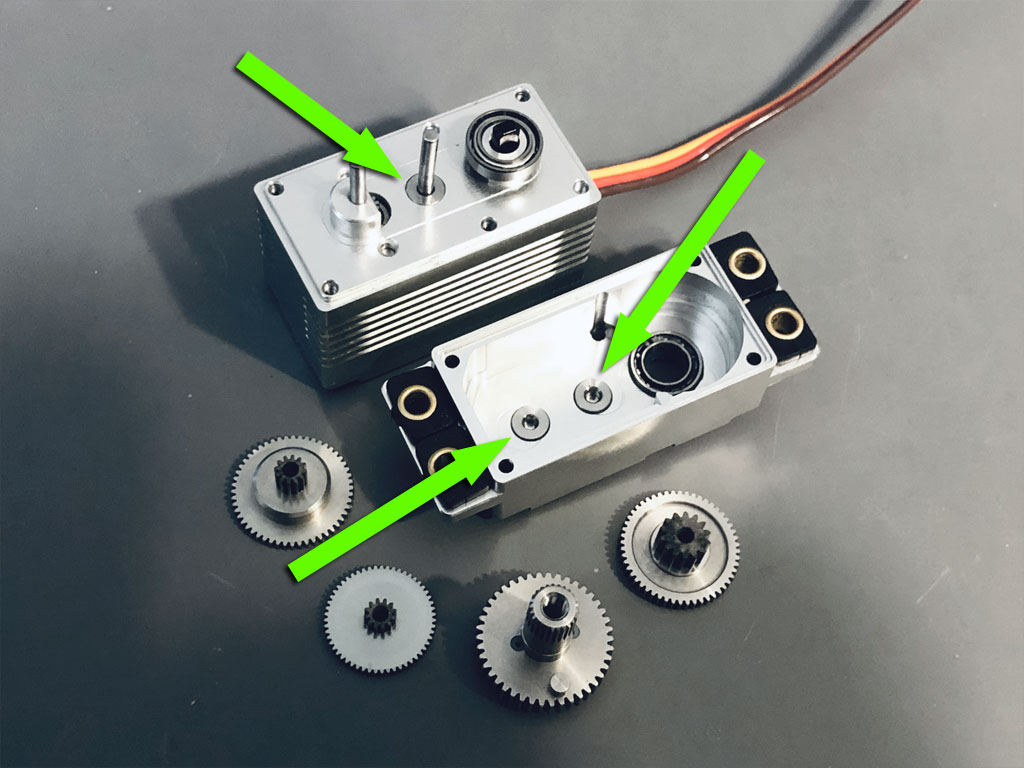

These are MUCH more rugged and heavily built (and more costly). For example, the gears and shafts inside are larger, which means they'll take more abuse. These are the guts of is a DS845BLHV but the DS635 and DS1155 are as alike as three peas in a pod!

- Rugged steel gears and shafts of the BLS2 series are larger than conventional servos

Add to it, from the outside it's easy to see the difference because the BLS2 servos use the ginormous 8mm, 15T spline instead of the familiar 6mm, 25T output spline shaft.

- The gnarly 8mm, 15 spline juxtaposed with a 6mm, 25T spline - big difference

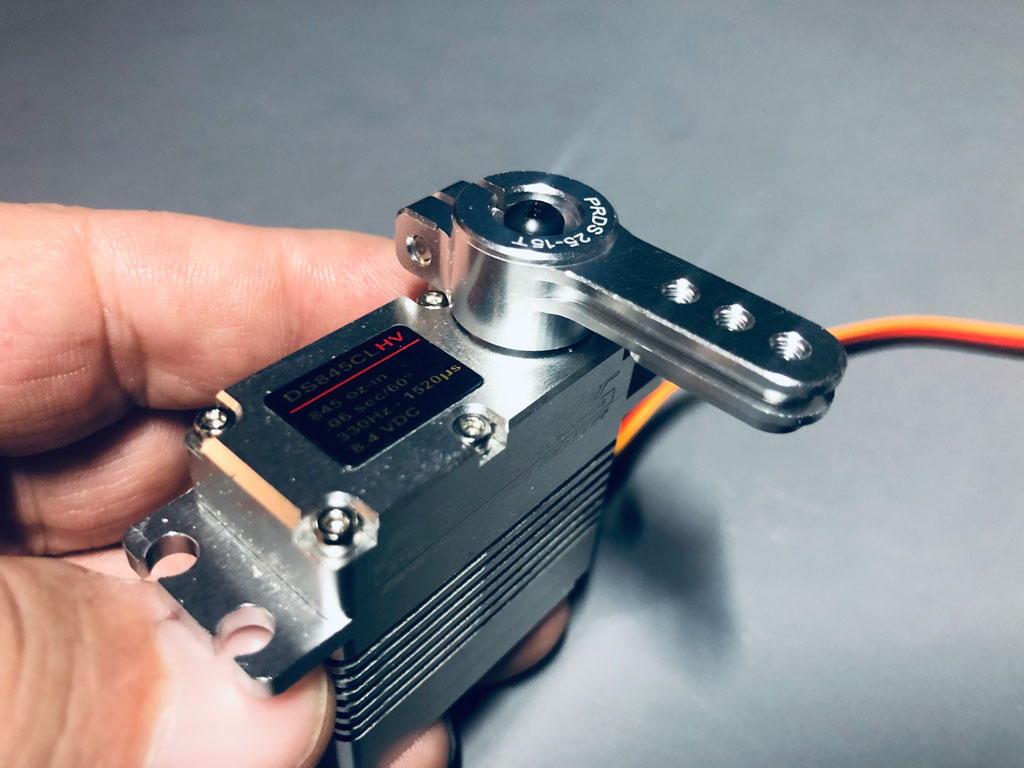

Of course, this also means the servo horn you need are not widely available from the aftermarket, so you likely will run ours, instead. We suggest the PDRS25-15T.

Fortunately, our horn works very nicely in the Mojave (yes, it has a 20mm mounting position (but also has two others, one each at 15mm and 25mm - thus increasing versatility just in case you subsequently want to repurpose your investment toward another application). By the way, we refer to this as a universal arm because it's so useful. So because it doesn't cost an arm and a leg, you'll be good to go with your Mojave equipped with this if you opt for a BLS2 servo.

Note; eyeball the H-beam cross section, which makes it immensely strong, and resistant to flexing under load. These are CNC-machined from a solid billet of 7075-T6 aircraft aluminum.

- ProModeler PDRS25-15T, M3 at 15, 20, & 25mm - the 25 refers to the outermost

Decoder ring and three types of motors

Before we get going on how-to select the right servo for *you*, let me first clue you in regarding what the letter/number combinations for our part numbers actually mean. This, because there is actually a method to our madness.

Anyway, if you're of a certain age you'll catch the reference about being so simple you don't need a decoder ring. But in fact, it's so straightforward and simple you'll wonder what the other guys are smoking when they invent model numbers that make no sense.

Here goes, for a DS845BLHV . . .

- DS = Digital Servo

- 845 = Torque rating in oz-in

- BL - Brushless motor (there are also DL and CL in our lineup)

- HV = High Voltage (to 8,4V)

. . . and if you don't know diddly about servo motors, review this article and after you grok what's going on, then you'll become the expert your mates call on for advice going forward when iron-pole, coreless, and brushless servo motors are being discussed.

Note; for this article, we took the various types of motors we all use, and by *we all* I mean *all* servo vendors, so not just us, but also Futaba, MKS, Savox, Spektrum, Hitec . . . everybody because these are the three motor types that exist.

Anyway, we chucked the one above in a lathe collet and cut it apart. Then we took this CU photo (and many more) to explain what's going on inside! Why? We figure the more you know about servos, the more critical you'll become of shitty products.

Heck, you don't even need to be an engineer, you just need a set of Eyeballs Mk II and you'll quickly come to recognize junk when you see it. You just need a little bit of knowledge nobody else shares. After all, knowledge is power!

DL-series

So first up, let's take a gander at how these different series servos are built beginning with the $50 servo we believe will work for those of you on a tight budget, the DS360DLHV. This one features hybrid construction.

Hybrid Construction

This means an alloy center section, which is CNC-machined from a solid billet of 6061-T6 aircraft aluminum, mating to a glass-filled nylon transmission section. Alloy and polymer, or plastic are a good combination to help keep the price down.

- Porcupine case - no logos - just cooling fins to shed heat better when working hard

Downside is . . . how to get the plastic to live in rugged conditions? For this, we reinforce it where the steel gear shafts are fitted. We make hardpoints using SAE65 bronze. These bits of metal are turned on a Swiss lathe to a very high precision and are insert molded within the case components.

Anyway, the end result of using bronze inserts in a plastic case is it's pretty darn rugged.

- Impact resistant glass-filled nylon 6.6, like what's used for a 9mm Glock handgun

Cheaply made servos don't use inserts and instead, set the steel gear shafts directly in plastic. So if you ever wondered why some servos go to Hell really quickly, now you know! It's likely because they lack this critical reinforcement?

So $50 for a DS360DLHV buys you a lot of the good stuff used in our pricier servos. Things like the alloy center with cooling fins, which are crucial when a servo is working hard, and bronze insert to improve durability. Unbreakable? Nope, but light and tough as hell.

Add to it, this servo has strong and very durable all-steel gears. Look around at Ferrari's F1 team car and NASCAR use - titanium gears? Nope, steel gears for them, also. Anyway, this servo meets three MIL-STDS (shock, vibration, and water intrusion), and is a bargain in the servo world. And we sell a butt load of them!

Heck, eyeball that gorgeous gear train, and take note of the o-rings (we use 13 in the assembly). Also, check out how the servo is assembled with 10 Socket Cap screws instead of the cheapo Phillips others use for entry level products. Take special notice how we use six bolts for the top case and four of these box in the output shaft bearing. Makes for a very stiff assembly.

- Take note of the shinny bits in the upper case, those are the bronze hardpoints . . . $50

Anyway, this DS360DLHV servo, will set you back $50 and if it'll do for your rig (great for many 4S applications), simply delivers a Hell of a lot of bang for the buck. However, while I might hesitate to use this with a 6S rig, for a 4S rig where the goal isn't to destroy the truck doing stupid YouTube shit, and instead it's having fun? Then yes, definitely!

Bottom line, if the rig is basically stock, then this servo will love a long and happy life (maybe until you clock a fence post or other immovable object when all bets are off). But if you do break it, it won't cost an arm and a leg to replace the case.

BLS0 - 415oz-in and amazing speed

So next up is a BLS0 series servo, the DS415BLHV. If you've noticed we have BLS0, BLS1, and BLS2 series brushless servos, and 0, 1, 2 doesn't mean anything but a way for us to classify them. As you saw with the $50 DS360DLHV, we don't make crap at any price point!

So the DS415BLHV will set you back $90 and if you've seen the guts of the DS360DLHV you've basically seen how this 415oz-in brushless servo is built. The basic difference is the motor, which is brushless like all the BLS series servos. This is what they look like if you had Superman's X-Ray vision.

- The yellow are o-rings, bronze color are hardpoints in the case

Yes, these brushless motors are mo' betta than an iron-pole or coreless motor because they're quicker, produce less heat, and last about 5X longer due to the lack of brushes to wear. Downside is they cost a Hell of a lot more, too.

And if we're honest, with a desert type rig that'll never see the race track, the super speed of the DS415BLHV probably doesn't make a heck of a lot of sense *because* you're not racing it's wasted. But if you are, then eyeball this servo closely, or consider the DS635BLHV, instead.

Anyway, unless you're not racing, for your 6S rig, straight up, it's our opinion you should skip the DS415BLHV servo altogether and instead, look to buy a DS505BLHV because for another $10, the DS505 gives you more torque plus the rugged durability that comes from an all-alloy case.

DS505/630/930 - BLS1 series

So the outside of aluminum servos all look pretty much the same. Some anodize them for looks, which ignore how anodizing reduces heat transfer. Others leave off cooling fins altogether (probably because they're very expensive to machine). And some competitors are dumb to the point of stupidity by anodizing *and* reducing the amount of cooling fins so they can laser etch logos and shit. Like what part of these are high performance servos are they missing? This isn't a beauty contest for crying out loud.

First and foremost, they have work to do, and if they're working hard then they *have* to shed heat as efficiently as possible! Nothing, and certainly not marketing BS should take precedence.

- This DS505BLVH is a tool, it has a purpose - wrong place for gimmicky marketing

So let's eyeball the inside of a DS505BLHV instead of the outside. Why? Because that's the part of a servo that matters, and interestingly enough, it's the part our competitors fail to show you. Us? We're proud to show you how ours are made!

This picture? It's the inside of a DS505 that failed but could be rebuilt. Why show this? Simple, it's because we're not ashamed of how well our servos can take a licking and come back for more! So why is this important? Because unless your money grows on trees, you don't buy disposable servos, you want ones you can actually repair economically.

Let me tell you a dirty secret of the Asian import servo business. They make them cheap and sell them dear, they offer your gears, but never tell you that if you tear them up, you almost certainly also damaged the case to the point it can't be repaired and hold tolerance (so the gears will wear out or break again quickly). Here's the gotcha, when you price a new case plus the gear set, they're not economical so your pretty bauble of a servo is one and done!

- This DS505 has been crashed and is being repaired, take note of the steel inserts

So this DS505BLHV, which at $100 is smack in the middle of our range, is nearly bullet proof. So I mentioned this one (picture above) has been crashed and undergoes repair. Review this article if you want to see the rest of the photos documenting the repair. Honestly, just using your eyes will inform you of what makes it worth your money to invest in ProModeler servos.

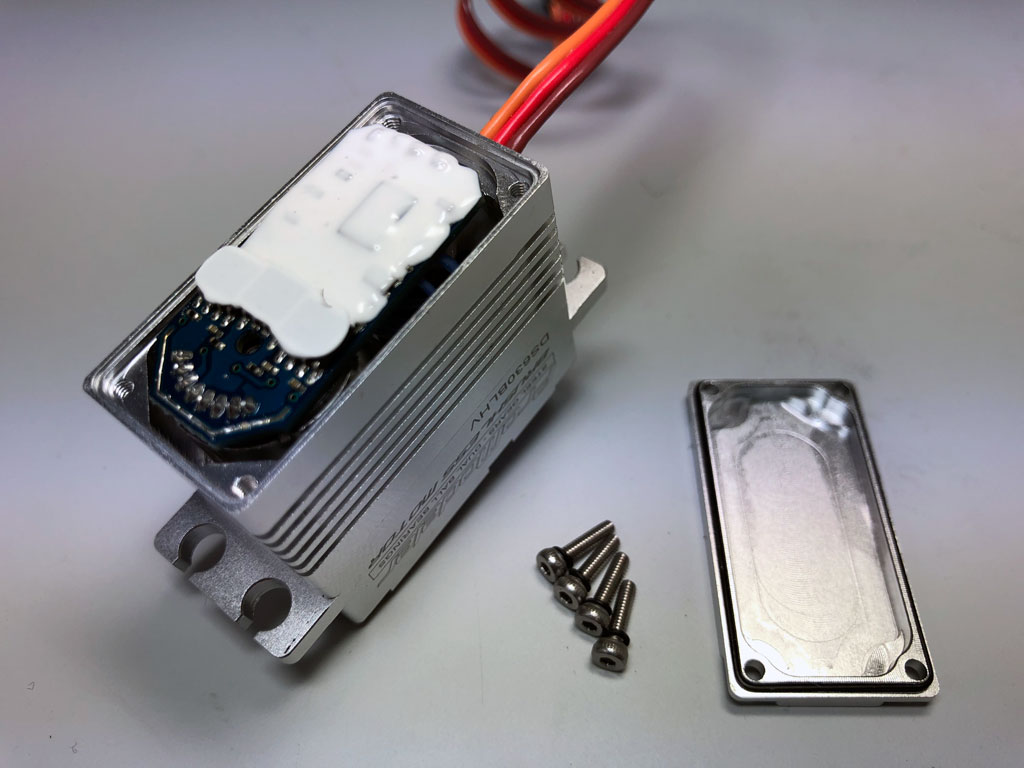

Note, the DS505 and DS630 are same-same except for the motor. So when we turn one over and take a look, you'll see a PCB covered in monkey snot. Actually it's potting compound, but we call it that because it's a stinky and sticky mess to apply. Once it sets up, the components are encased and won't move.

This is the secret sauce for how these servos meet MIL-STDS for shock and vibration. And if you eyeball this photo closely, you'll spot the o-rings, which give it another MIL-STD for water intrusion, also. And note also, no cheesy Phillips head screws, these are all socket cap bolts with o-rings beneath the heads, also.

- The white stuff is potting compound, sometimes it's black, it's aerospace technology

So the last of the three BLS1 servos is the DS930. Built pretty much the same as the DS505 and DS630, but with larger gears and stronger motor, it sits in a curious place between the DS635BLHV and DS845BLHV price-wise, but also sporting the highly compatible 25T spline shaft.

- Painfully plain compared to the gaudy exterior of competing servos - performance speaks

This brings us to the BLS2 servos, the hairy beats of our line up consisting of the uber fast DS635, plus the rugged grunt of the DS845 and DS1155BLHV servos.

BLS2 - DS635BLHV, DS845BLHV, and DS1155BLHV servos

What separates the DSS635 from the other two isn't just the difference in torque but the blinding speed. It is an entirely different beast not just for these two but from all others in the line up and the world.

What the BLS2 have in common with each other is their rugged constructions. Perhaps the best way to see this is to compare internals to a worthy and well know Savox SB-2280SG, which any hobby dealer in the country would delight in selling you.

Power to the people

Look, don't forget, servos making this kind of torque, have to be fed enough current. Like your stock BEC will likely feed a DS360, DS505, maybe even a DS630. But if you've decided one of our hairy servos is what you want for your rig, then don't expect your stock ESC/BEC to cut it.

Basically, you're either going to need to pony up for an aftermarket ESC, or if you're pretty happy with the stock motor and speed control, then we can offer you a solution that won't break the bank. These being a standalone BEC or a dedicated battery pack. Like if money is tight, maybe try it with your existing BEC and if you're happy, great! And if not, then power it with either great standalone BEC like is this CC BEC PRO 20 (we offer two, one is waterproof) or if you're comfortable charging another pack, then treat the rig like one with nitro-power. Use an inexpensive dedicated 2S battery,If you do, remember to also order two 4" extensions. These will be where you make/break power to the battery. This inexpensive B2850 pack is all you need.

A nice advantage of the dedicated pack is you get longer runs since the propulsion pack is not being parasitized for juice to run control-electronics. These articles will help guide you further.

Conclusion

There are eight ProModeler servos suitable for your Mojave. Which one is best for you? It depends! If money is tight but you don't mind spending for good stuff, the DS505BLHV or maybe the DS630BLHV are probably the best deal for a modified 6S rig.

If your wallet can stand it, a BLS2 servo is without question giving you the best your money can buy. You have three to choose form ranging from 635oz-in through 845oz-in, and topping out at 1155oz-in. Which one is best for you? What's your rig weigh and how fast is it, and how much tire are you carrying. This is what it comes down to.

For a 4S rig, the DS360DLHV is a reasonable alternative to the stock servo that gives you great performance and durability, but a DS505BLHV is probably the best bang for the buck.

What makes ProModeler servos best for you? It's the time and attention that goes into the details. There's a saying, it's attributed to an architect name of van der Rohe and he said, God is in the details. By this, he meant the same think we think, pay attention to the details and the big picture takes care of itself.

For us, it's down to the parts, better gears, better motors, use o-rings to seal them, put hard points in the cases to make them durable, use the best potentiometer money can buy, the Japanese Noble 1mc, and ignore the nonsense like laser art and anodizing is great for attracting immature youth. Instead, focus on offering value and delivering great bang for the buck. Those who know the difference between flash and value will pay attention. Make the product for those people.

Thanks for reading, we hope we've provided a good glimpse of what separates our servos from competitors and in doing so, have helped guided you toward selecting the best servo for your needs. If you have any questions, reach out via email: info@promodeler.com or by phone: 407-302-3361 and we'll try and help.

Last thing, our thanks to Steve 'Cheez' Wilson for generously sharing photos of his rig with us.