This mechanical kit is for fitting ProModeler DS635/845 or DS1155 standard size servos to an X-MAXX. This does not fit other brand servos and is not for sale separately. Kit includes mount adapters, servo horn, and hardware.

Background:

With the X-MAXX, Traxxas unleashed a beast on the modeling world. As delivered, it's a great introduction to the sport, but skilled drivers soon discover the limits of the stock steering servo. While Traxxas offer metal gear upgrades, they ultimately responded with the #7749 mount adapter, which lets drivers fit a superior standard size steering servo.

Two stood out; the ProModeler DS930BLHV and Savox SB2290SG Monster. While the Savox is pushed by hobby dealers, ProModeler servos are available direct.

Digging into the specs, the ProModeler is both stronger and faster . . .

- Torque: 930oz-in vs. 694oz-in

- Speed: 0.010sec/60° vs 0.13sec/60°

. . . and with regard to build quality, it's also better.

For example, the ProModeler alloy case is bronze reinforced where the steel gear shafts fit while the Savox fits steel directly to aluminum. Both use o-rings to seal the case, but while ProModeler uses 13, Savox only uses 2. And in terms of vibration and shock resistance, with ProModeler you get . . .

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

Slam dunk ProModeler, end of story, right? Nope! Why not? Because we don't recommend a DS930BLHV for use with an X-MAXX. What?!?

Confused? It's simple; the reason we don't recommend the DS930 is we've learned it doesn't hold up. Surprised we'd admit this? Don't be, it's because we're a company founded by engineers and hiding from facts isn't our style. So we've developed a line of 3 standard-size servos that 'will' hold up. These are the DS635BLHV, DS845BLHV, and DS1155BLV.

Here's how they came about. You see, we get servos back that have failed. And you don't have to be an engineer to see what's going on. Basically, X-MAXX owners are destroying DS930 gear sets. And look, we can't speak for the Asian import, but we figure the same thing is happening with theirs because they both share very similar construction.

Anyway, this is a photo of what we're seeing happen . . .

- The best steel-gear money can buy . . . not proof against curbs and roots!

Note, in the photo above, that steel shaft is literally TWISTED out of shape! And it's not because we're using cheap ass materials, it's twisted despite our using the very best steel available. Why?

Simply put, it's because the X-MAXX is such a big, heavy, and fast rig we're seeing the proverbial irresistible force meeting the immovable object! In short, something's gotta give and that something are gears, which when we open the servo often look like this . . .

- Doesn't happen to all DS930 (or the Savox) but it's not uncommon, either!

And note two things; first, this doesn't happen with aircraft (not even in a crash), and second, it only rarely happens with any other vehicle. This is almost 100% an X-MAXX phenomena.

So in light of the fact gear teeth, which remember are made of STEEL, are being sheared off it means we're talking incredible forces! Also note; a loaded rig weighs about as much as a bowling ball. Thing is, an X-MAXX goes way faster than you can toss a bowling ball, so now do you understand how much force is involved? Anyway, the only 'real' answer involves larger gears. Thing is, how do you stuff larger gears into the servo without making it a bunch larger? If it were easy everybody would be doing it!

So here's the thing, one morning waking up from a dream, the solution hit me. Seriously, this problem had been bothering me so much I'd actually begun dreaming about it! But I suddenly had it - like a lighting bolt striking me - I'd realized how we could rearrange the internal components to let us increase the gear size (without also increasing the size of the servo).

Anyway, for years I've made a habit of keeping a pen and pad of paper next to my bed (for just this kind of thing), and it really paid off this time! So before the dream faded, I sketched out my thoughts. And honestly, it's really quite simple. It merely involves relocating the potentiometer lower into the case, and then using that space to create a well to accept larger gears - ones that are about twice as long as the ones we'd been using . . .

- Offering twice the gear area, this gearbox design is patent pending.

And note; if you look at model servos going back decades, they all use a common three shaft layout with gears raised from a common plane (exactly like what we use with the DS930 and Savox uses for their 2290SG). However, in going to a dual-plane layout, along with an added stage, what we've done is invent a totally new gear layout. It's one that lets us increase the gear size while retaining the same volume. And because it's a totally new concept, it's patent pending!

Anyway, that same day, I jumped on the CAD workstation and began fleshing out my idea (to see if it would work). and to my immense satisfaction, although I worked until past midnight, it all came together perfectly. What resulted from the long hours at the workstation rendered out like this . . .

And note; it's important to realize that just as we first developed the DS505, which led to the DS630, and then culminated with the DS930, with the DS1155 we went the other way around. First we created the DS1155, then the DS845, and finally, the DS635. Point being, gears big enough for the DS1155 are serious overkill in the DS635 and DS845, capice?

So like the DS505/630/930 are similar, the DS635/845/1155 series are also three peas in a pod, e.g. built very much in the same way. What does this difference in gear dimensions mean in practice? Well, the picture below explains a lot . . .

And note; while this photo compares the relative sizes between the DS1155 and 2290SG gear train, in truth the DS930 and 2290SG gear trains are about the same size.

Point being, if you grok what this picture actually means, then you'll also understand why we don't recommend the DS930 - at least 'not' for such large heavy rigs as the Traxxas X-MAXX!

Simply put, in standard size, the DS635/845/1155 are a better way to go!

The rest of the story

Paul Harvey was famous for his 'rest of the story'. So with apologies for not being nearly as good a storyteller, kindly allow me to share what came next.

So we put the new servo design into production. Meanwhile, a good customer came to me with an idea for a mount similar to the Traxxas #7749, but different in that it allowed fitting DS1155. We gave him a production-order (and he did a nice job 3D printing them). Once delivered, they became our part #7749X and in combination with the PDRS19F-25T servo horn, the S7749A mechanical kit, alloy. And over time, what we hoped was proved out. What's that?

Simple! X-MAXX owners tearing up the gears of an DS1155 have become very rare. No, they're not unbreakable, but it's really, really rare. Only thing is, then we learned the polymer mount had become the weak link in the chain.

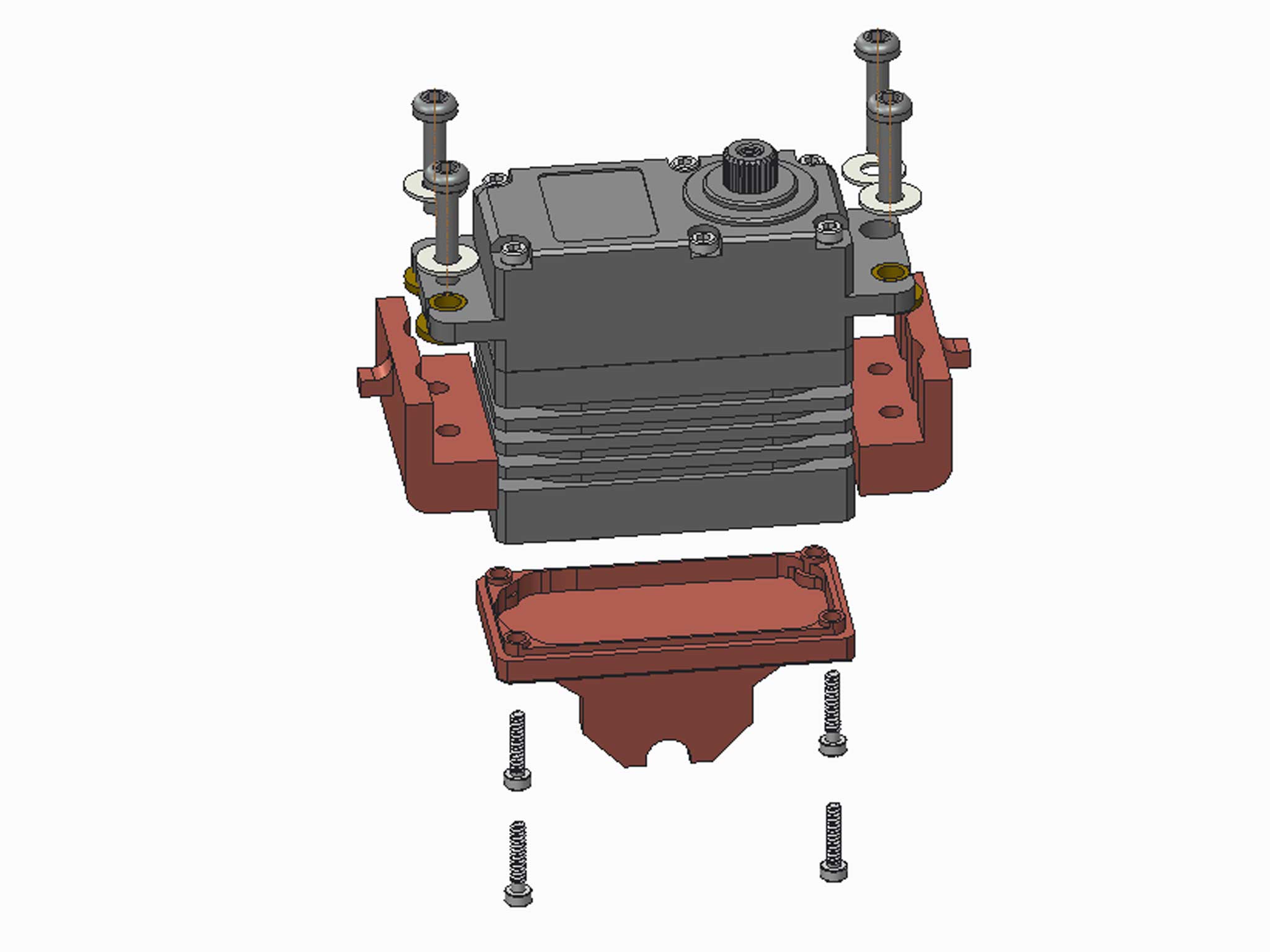

So next I turned my hand to designing an all new type of mount. One designed to better mate the servo within an X-MAXX. Rendered out of the CAD workstation it looks like this . . .

- X-MAXX mount for our DS635/845/1155 servos . . . also patent pending

And that, folks - in a nutshell - is the story of America. You have an idea, you put in the hard work, and a product is born. Bottom line? When you're dealing with big forces, the only 'really' good answer is . . . bigger gears!

Anyway, this alloy mechanical mounting kit is designed expressly for fitting a DS635/845 and DS1155 within an X-MAXX. If for whatever reason you want to use a smaller gear servo (like the DS930 or 2290SG), then no offense, you have to rely on the Traxxas part because we don't want any part of it.

Included are mount components, which are CNC-machined from a solid billet of 6061-T6 aircraft aluminum. We also supply you with grade 12.9 Allen-head mounting hardware, plus our PDRS19F-25T control horn together as a combo (e.g. one part number to make it easy).

And this is what the mechanical kit looks like after you spend a few minutes replacing the servo's existing electronics cover, adding the beam adapters, and the special horn. Pretty sweet, eh?

- The X-MAXX mechanical kit, alloy - created to update the stock 2085X

Folks ask us about buying just the control horn. Since we're in business to sell stuff, this link takes you to where you can buy just the X-MAXX control horn without the rest of the mechanical kit, alloy. Just don't say nobody gave you a heads up regarding installing this on another brand of servo, OK?

PDRS19F-25T X-MAXX Control Horn